BOPP EVA Pre-Coated Film

- Product name: BOPP EVA Pre-Coated Film

- Adhesive: EVA

- Surface: Glossy/Matt

- Thickness: 17mic~27mic

- Width: 300mm~1890mm

- Length: 200m~4000m

- Overview

- Specification

- Advantages

- End-To-End Customer Support

- After-sales Service

- Recommended Products

Product description:

Thermal lamination film is a pre-coated adhesive material that delivers high-quality laminating results through a simple heat and pressure application-no extra adhesives required. It effectively improves the durability, smudge resistance, and overall appearance of printed items. This finishing method is quick, clean, and eco-friendly.

Project Showcase:

TicketLabel Hangtag Greeting Card

Gift BoxCalenderBrochureBox

Specification:

|

Product name |

BOPP pre-coated film |

|

Adhesive |

EVA |

|

Surface |

Glossy/Matt |

|

Thickness |

17mic~27mic |

|

Width |

300mm~1890mm |

|

Length |

200m~4000m |

|

Core |

1 inch(25.4mm)/3 inch(76.2mm) |

|

Packaging |

Top and bottom box/Carton box |

|

Laminating temp. |

105℃~120℃ |

|

Place of Origin |

Guangdong, China |

Advantages:

- Exceptional Clarity & Enhanced Appearance:

It offers superior optical clarity, which significantly boosts the vibrancy of colors and sharpness of images underneath. It is available in both high glossy (for a shiny, premium look) and matt (to reduce glare and provide a sophisticated, non-reflective finish) options, greatly improving the overall visual appeal of the product.

- Excellent Moisture and Water Resistance:

It acts as a highly effective barrier against water, humidity, and other liquids. This protective quality prevents prints from warping, smudging, or deteriorating, making it ideal for products that might be exposed to moisture or require frequent handling.

- High Durability and Tear Resistance:

The biaxial orientation process during manufacturing gives BOPP film remarkable strength. It significantly increases the tear, puncture, and abrasion resistance of the laminated material, thereby extending its lifespan—especially important for items like book covers, menus, and packaging that undergo heavy use.

- Cost-Effectiveness:

Compared to other film types (such as Nylon or PET), BOPP is generally more affordable, providing a high-quality, protective finish at a competitive price point. This makes it an economical solution for a wide range of projects, particularly high-volume jobs.

End-To-End Customer Support:

Customized Film Solutions:

Solve Your Specific Pain Points

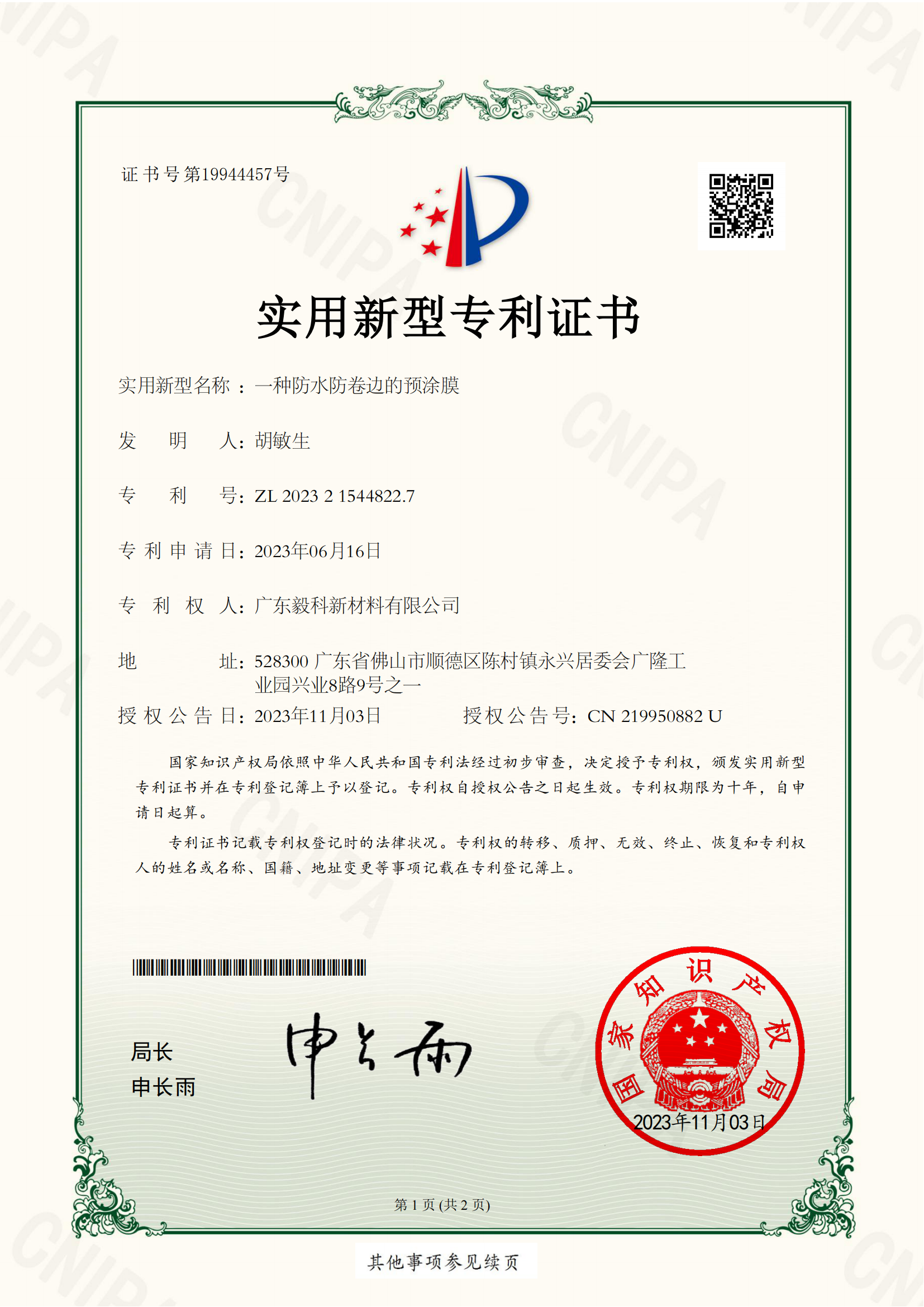

Edge warping of heat-intolerant printing materials after laminating

SOLUTION:LowTemperature Thermal Lamination Film

Delamination of digital toner printings after laminating

SOLUTION:Digital Thermal Lamination Film

Low adhesive of inkjet printings after laminating

SOLUTION:Thermal Lamination Film for Inkjet Printing

Solution:

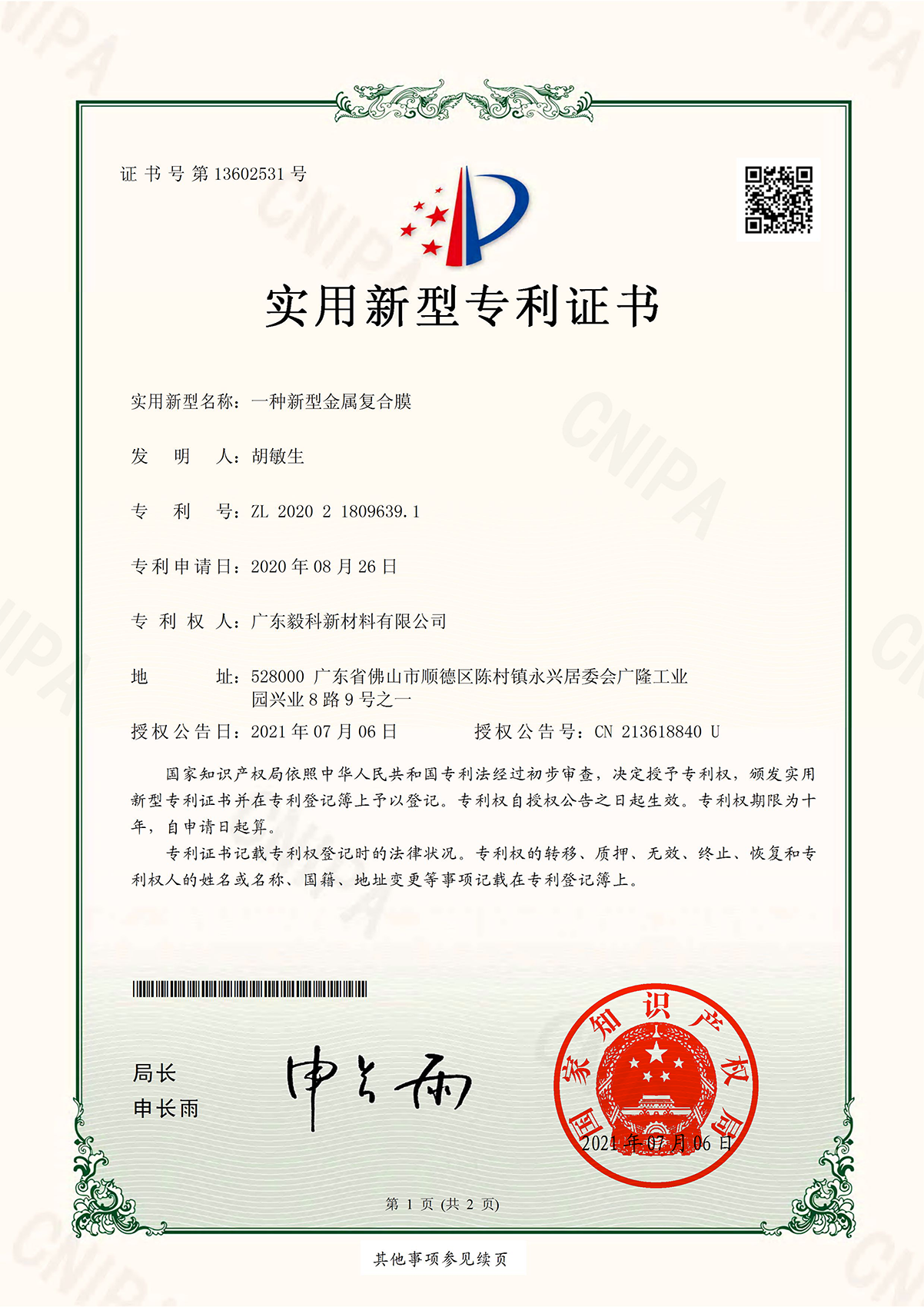

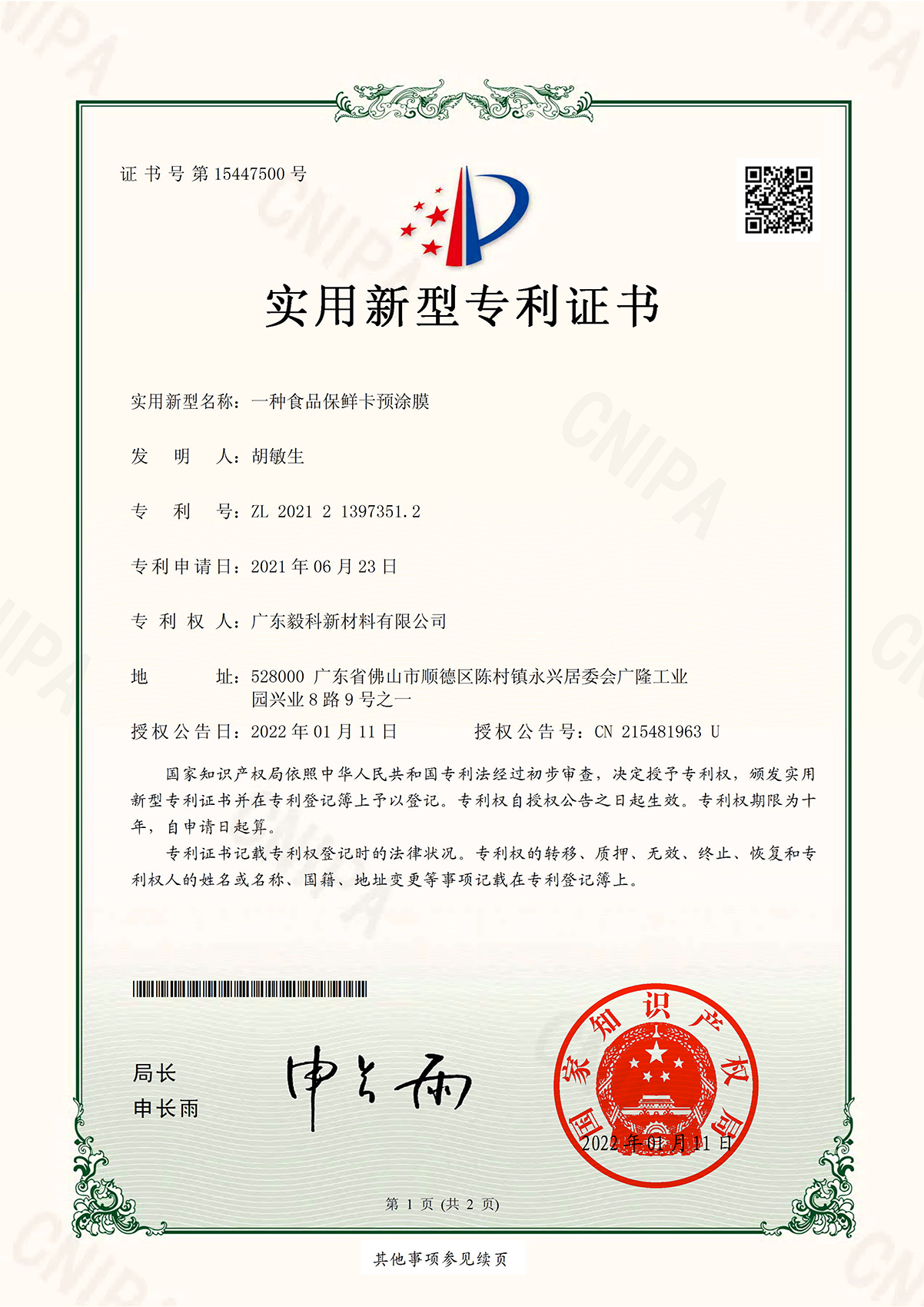

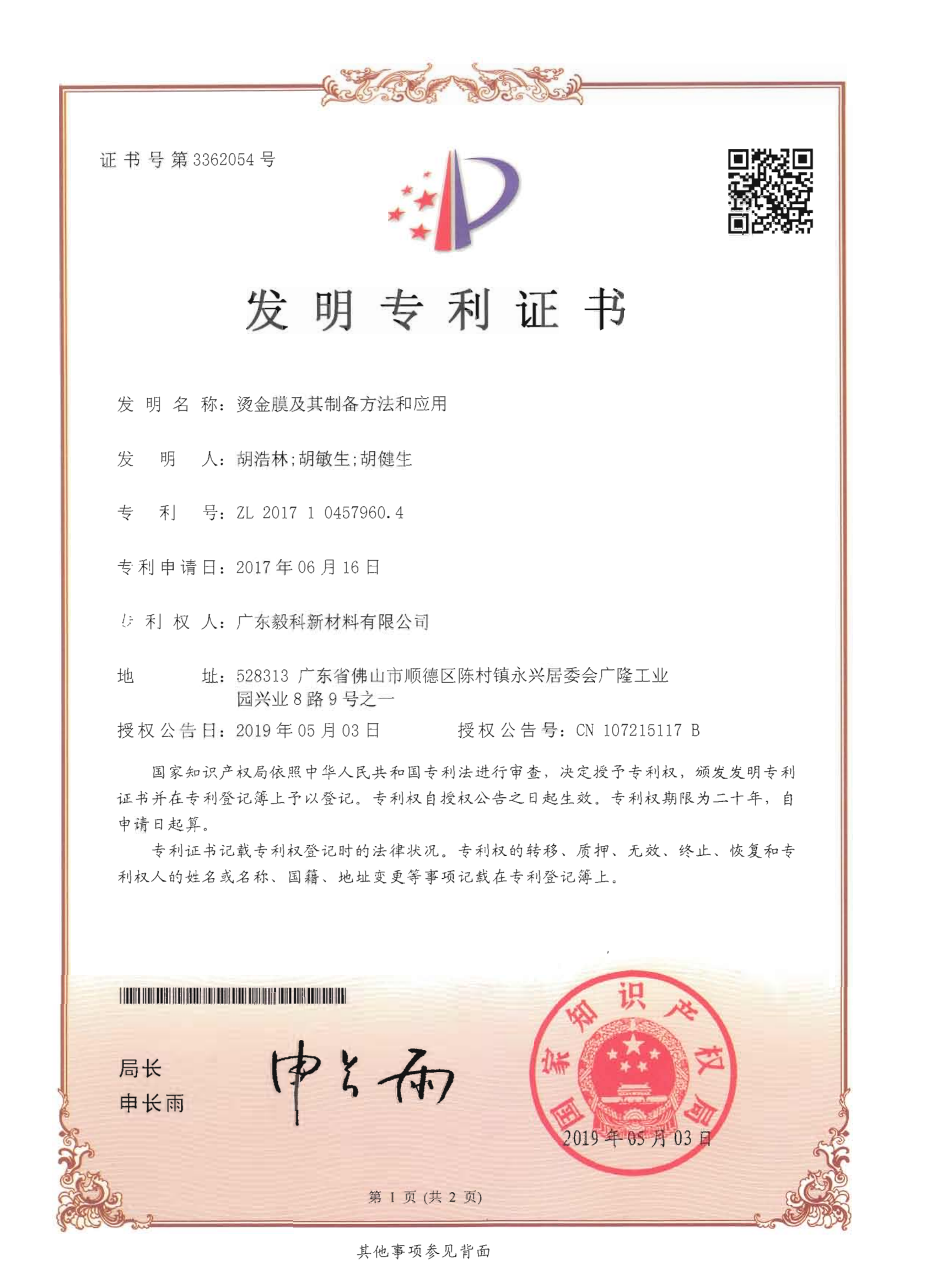

Deep Cooperation with School's Research Department Delivering Customized Solution

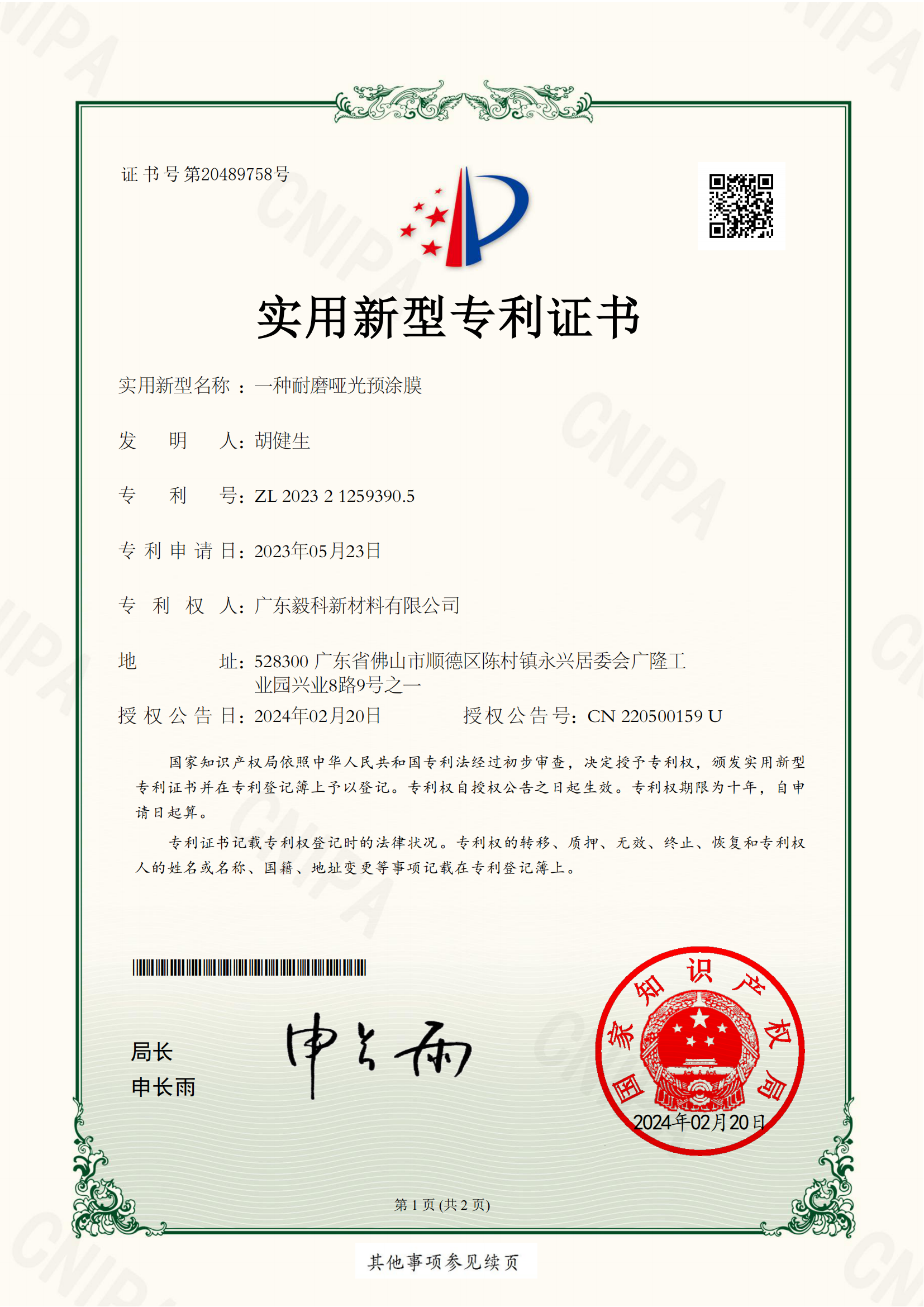

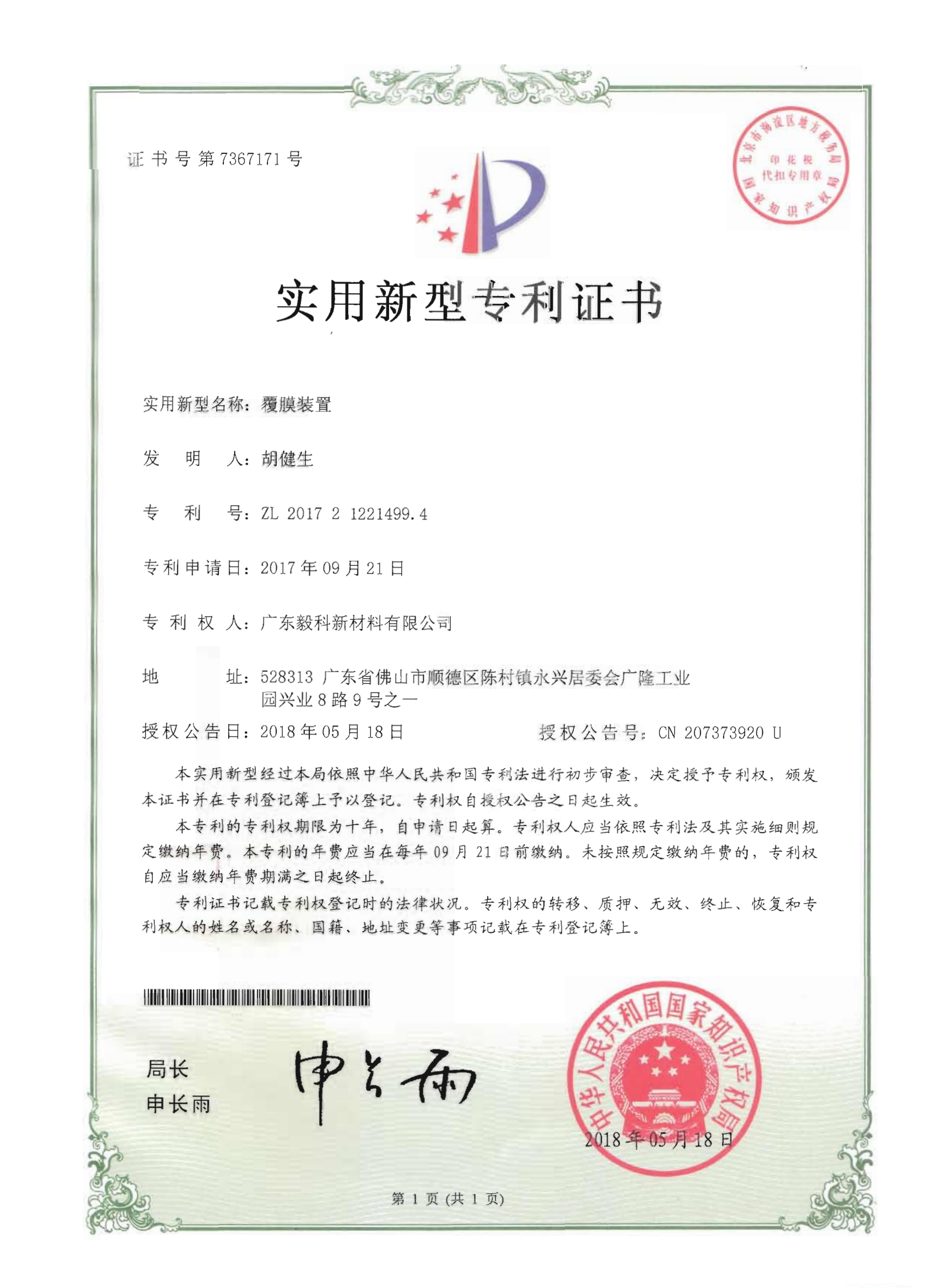

Compliance:

RoHS & REACH & Food Contact Material Triple-Certified

Packaging & Shipping:

FAQ:

Q1:Are you a factory or a trading company?

A: We are a company integrating R&D, production and sales.

Q2: How do you ensure the quality of your products?

A: We do end-to-end quality control-real time thickness check, corona value detection, bond strength testing, performance packaging.

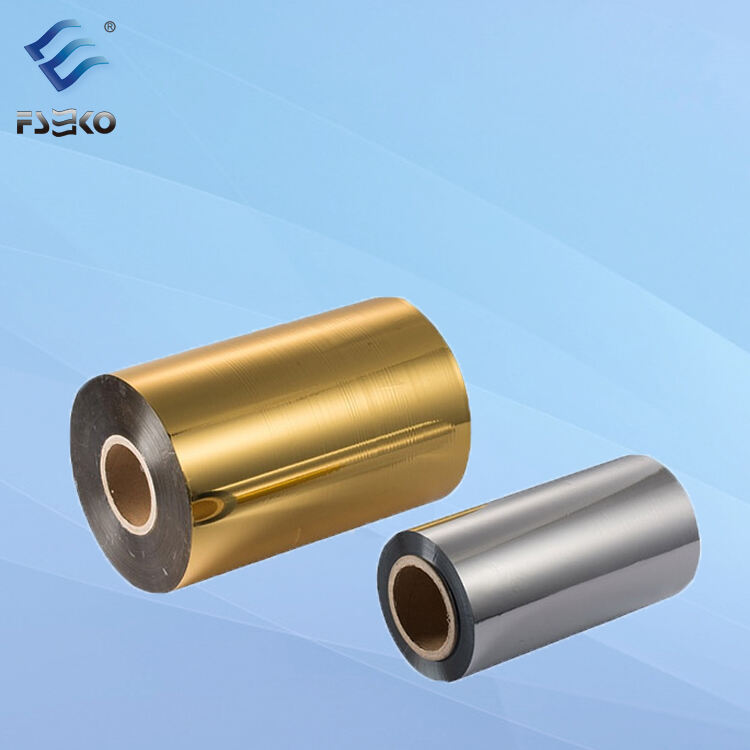

Q3: What is your main products?

A: EKO has a broad product portfolio by catering to a wide range of industry needs, including BOPP thermal lamination film, digital super sticky thermal lamination film, thermal lamination film for inkjet printing, digital toner foil, DTF film & paper, heat sealable film, etc..

Q4: Can I get some samples or trial order for trying?

A: Yes, we provide free samples, the sample size is 320mm*30m per roll. You only need to pay for the shipping cost.

Q5: What services can we get?

A: We provide end-to-end customer support including professional customer service, customized solution, free samples, trial order, product information pack, technical consulting, full logistics tracking and feedback, comprehensive customer complaint process.

Q6: What payment terms do you offer?

A: We offer EXW, FOB, CIF, DAP, DDP, etc..