Velvety Thermal Lamination Film

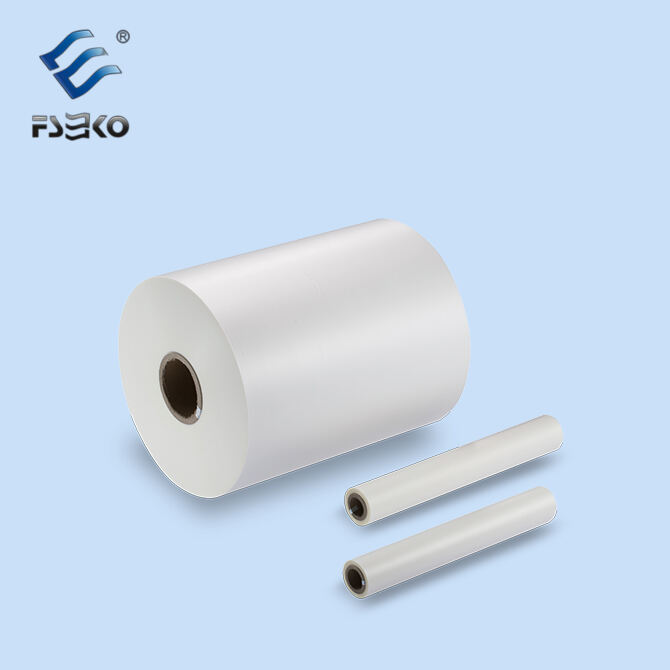

- Product name: Velvety Thermal Lamination Film

- Adhesive: EVA

- Surface: Matt and velvety

- Thickness: 30mic

- Width: 300mm~1890mm

- Length: 200m~4000m

- Overview

- Specification

- Advantages

- End-To-End Customer Support

- After-sales Service

- Recommended Products

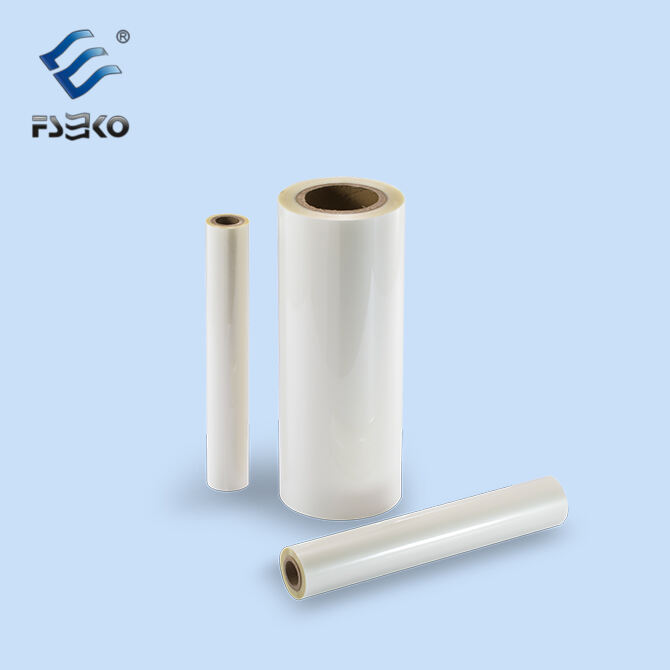

Product description:

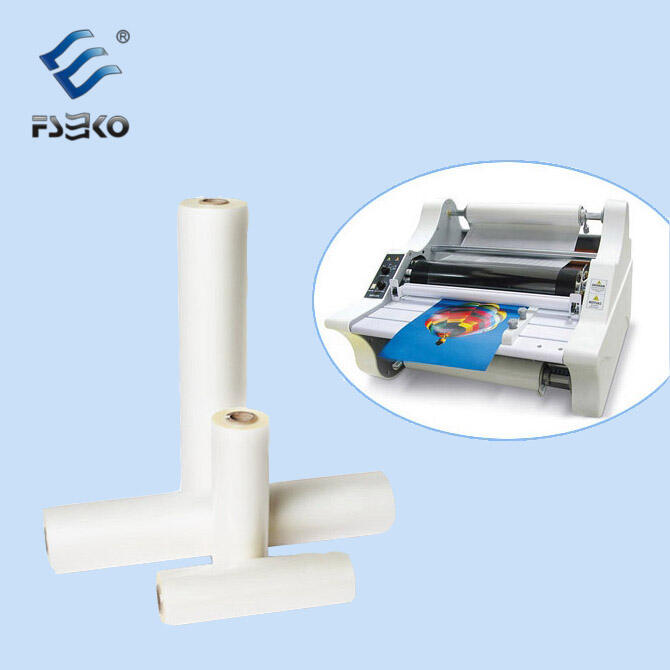

Soft Touch thermal lamination film is a premium-grade finishing material designed to provide printed products with an exceptionally smooth, velvety surface texture. This specialized film is coated with a non-glossy and special treatment layer that creates a subtle and luxurious tactile experience. Applied using standard thermal lamination equipment, it enhances both the visual appeal and physical feel of printed items—making it a popular choice for high-end branding, packaging, and promotional materials where sensory engagement and elegance are critical.

Project Showcase:

TicketLabel Hangtag Greeting Card

Gift BoxCalenderBrochureBox

Specification:

|

Product name |

Velvety Thermal Lamination Film |

|

Adhesive |

EVA |

|

Surface |

Matt and velvety |

|

Thickness |

30mic |

|

Width |

300mm~1890mm |

|

Length |

200m~4000m |

|

Core |

1 inch(25.4mm)/3 inch(76.2mm) |

|

Packaging |

Top and bottom box/Carton box |

|

Laminating temp. |

105℃~120℃ |

|

Place of Origin |

Guangdong, China |

Advantages:

- Luxurious Tactile Experience:

Delivers a distinctive soft, silky feel that invites touch and significantly elevates the perceived quality of the product.

- Elegant Matt Appearance:

Provides a sophisticated non-reflective finish that reduces glare and enhances readability, making it ideal for text-heavy designs or premium visual presentations.

- Fingerprint and Smudge Resistance:

The non-slip textured surface helps conceal fingerprints, dust, and minor scratches, maintaining a clean and professional look even after repeated handling.

- Excellent Print Protection:

Shields against moisture, UV exposure, and minor chemicals, helping preserve color vibrancy and image clarity over time.

- Brand Differentiation:

Adds a sensory element to print materials, helping brands stand out in competitive markets through unique tactile appeal.

End-To-End Customer Support:

Customized Film Solutions:

Solve Your Specific Pain Points

Edge warping of heat-intolerant printing materials after laminating

SOLUTION:LowTemperature Thermal Lamination Film

Delamination of digital toner printings after laminating

SOLUTION:Digital Thermal Lamination Film

Low adhesive of inkjet printings after laminating

SOLUTION:Thermal Lamination Film for Inkjet Printing

Solution:

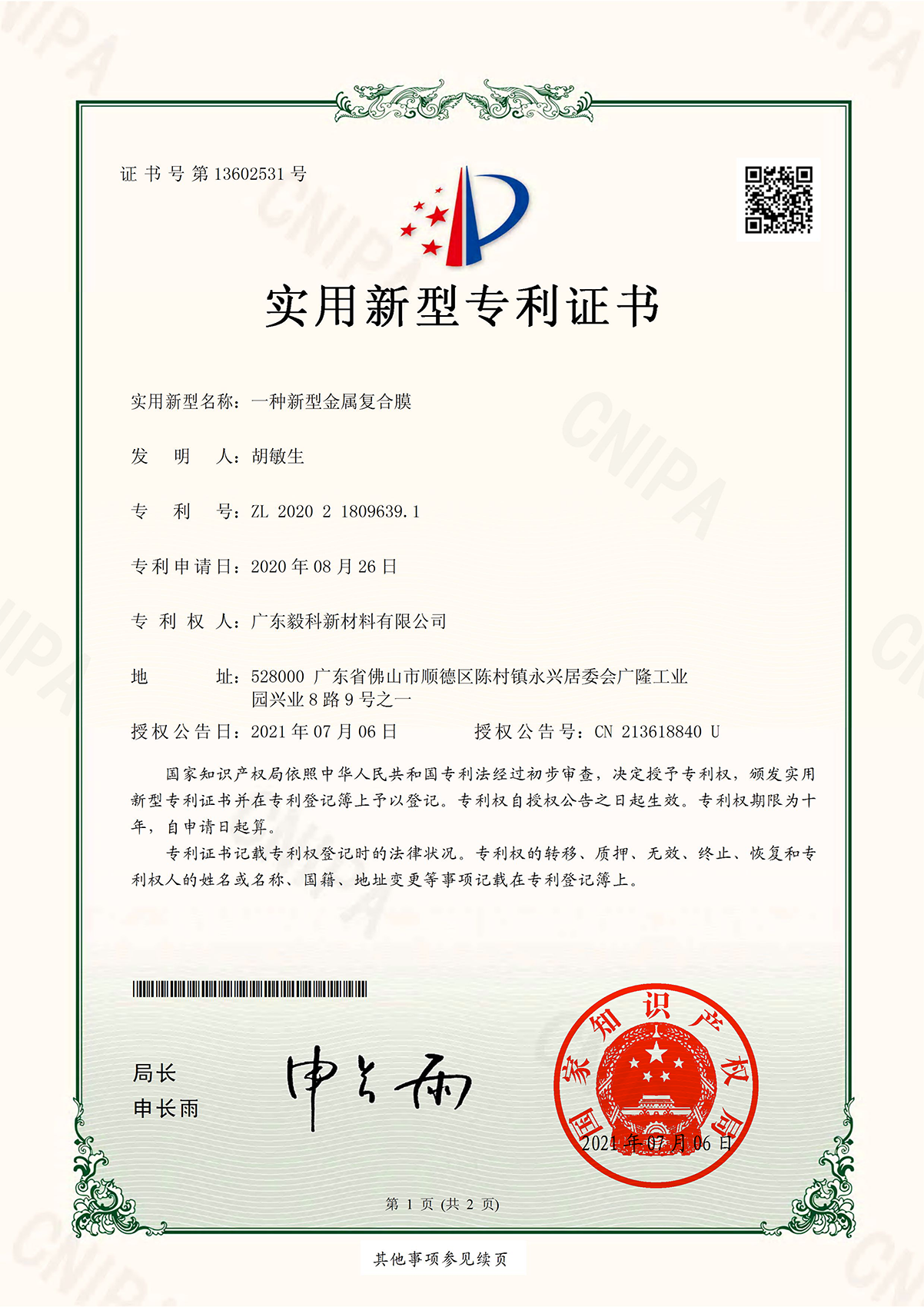

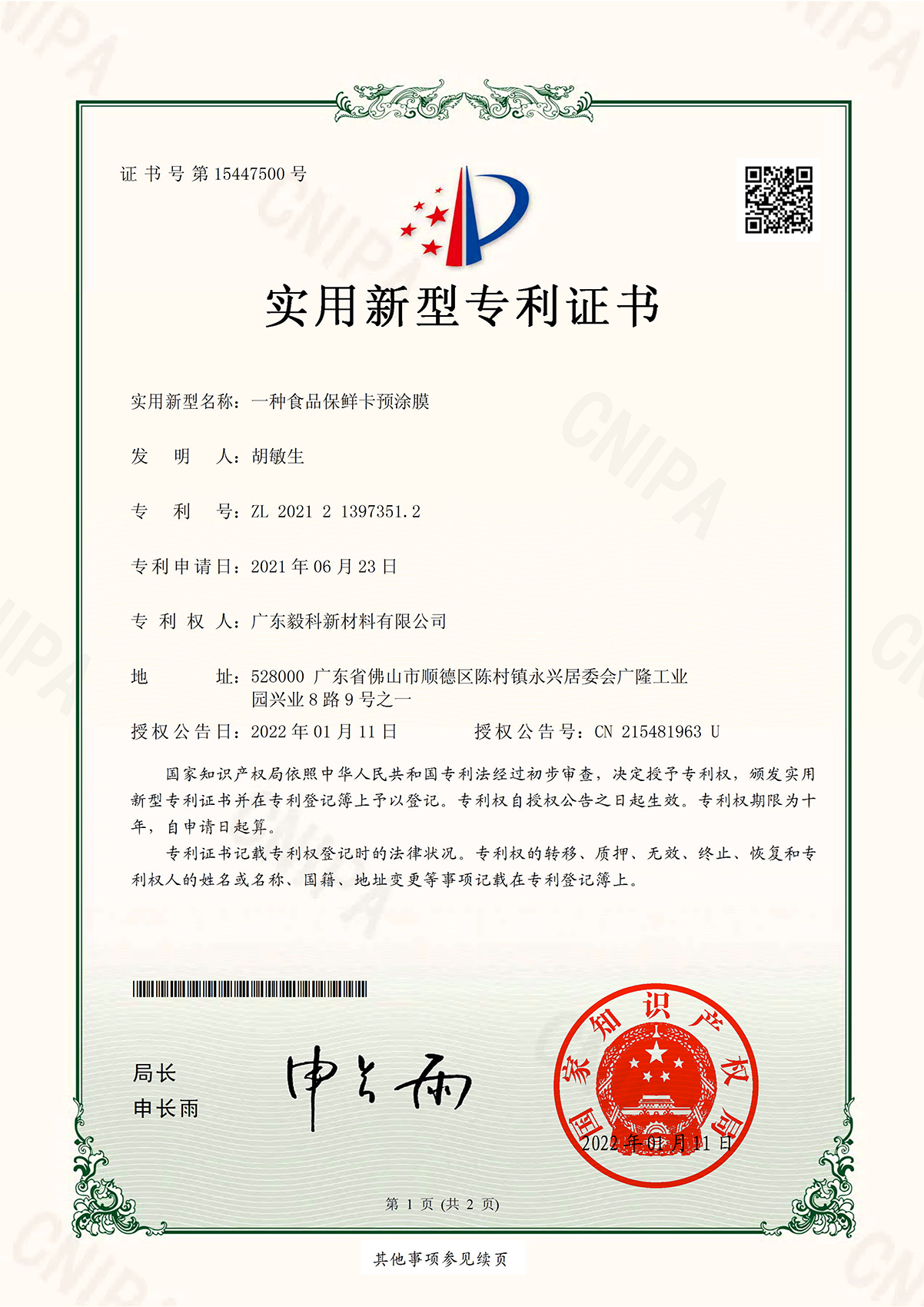

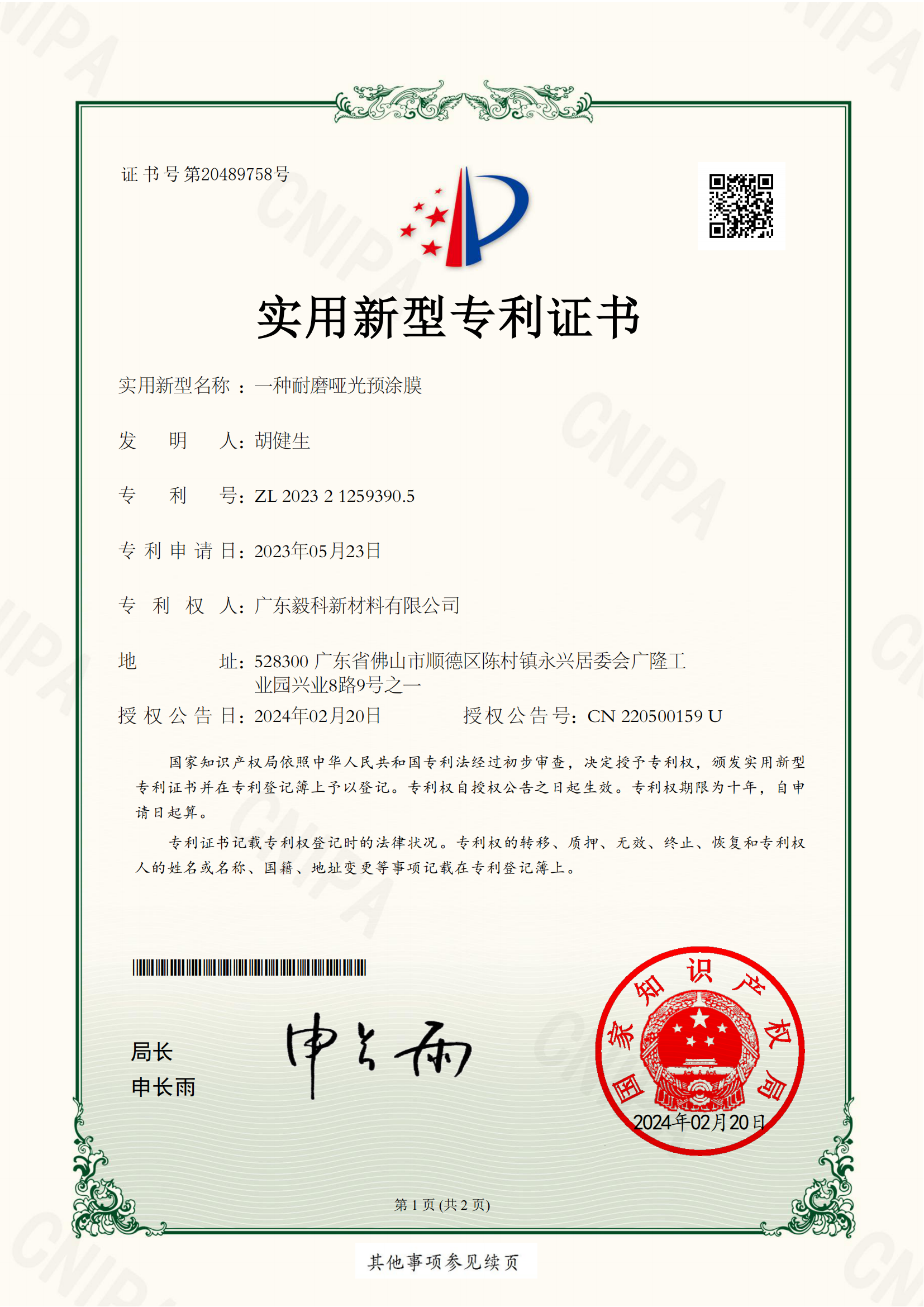

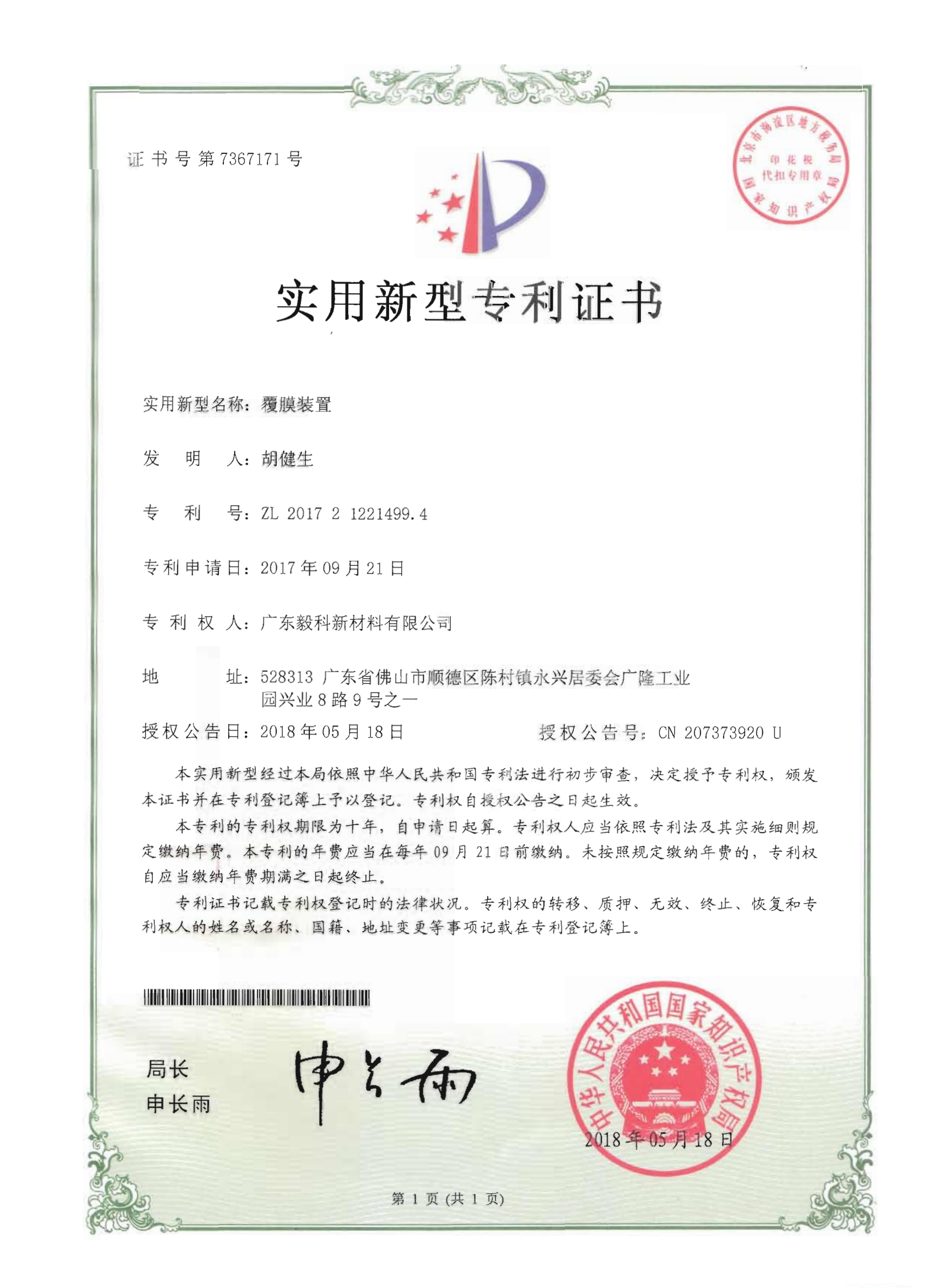

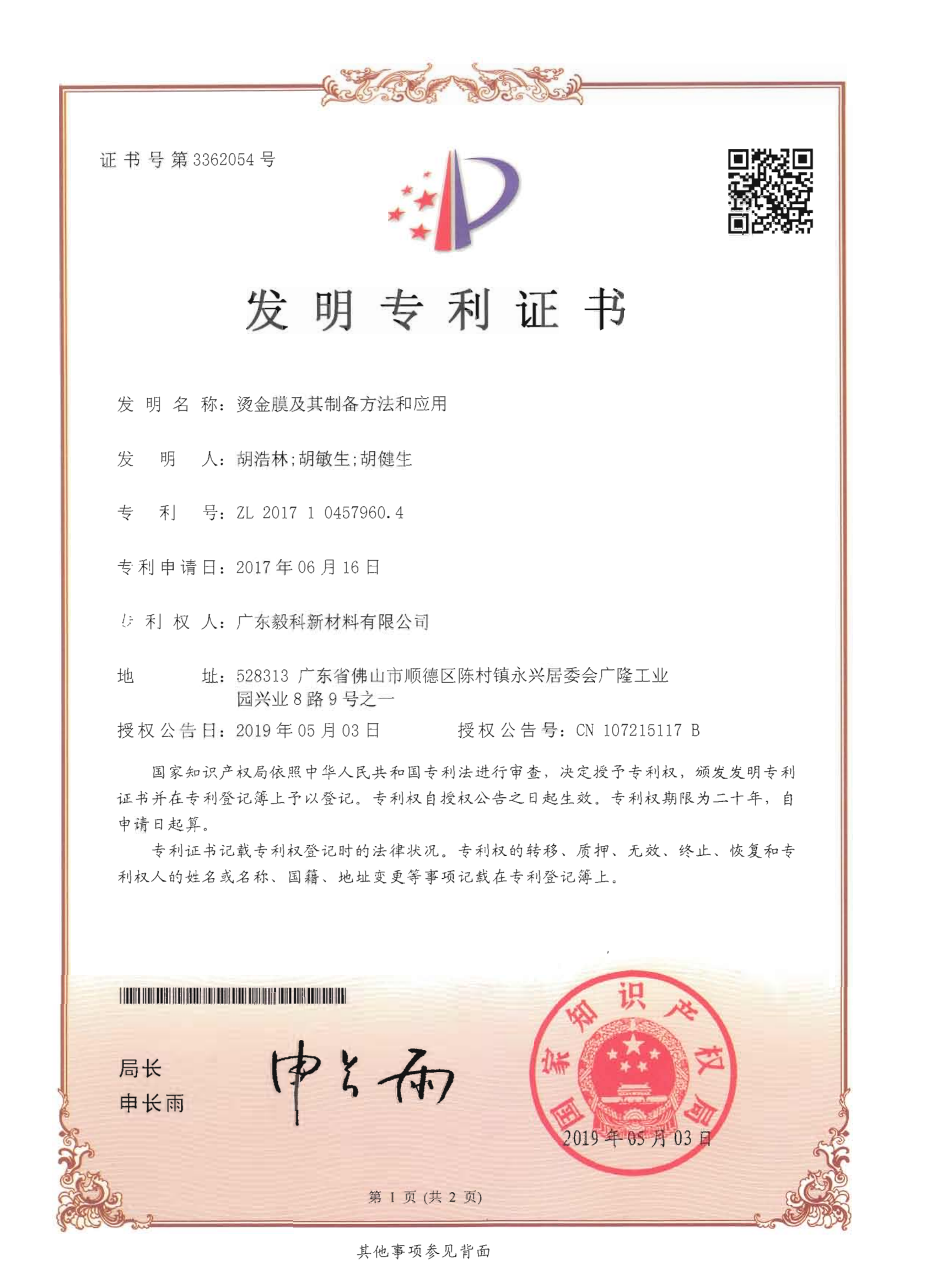

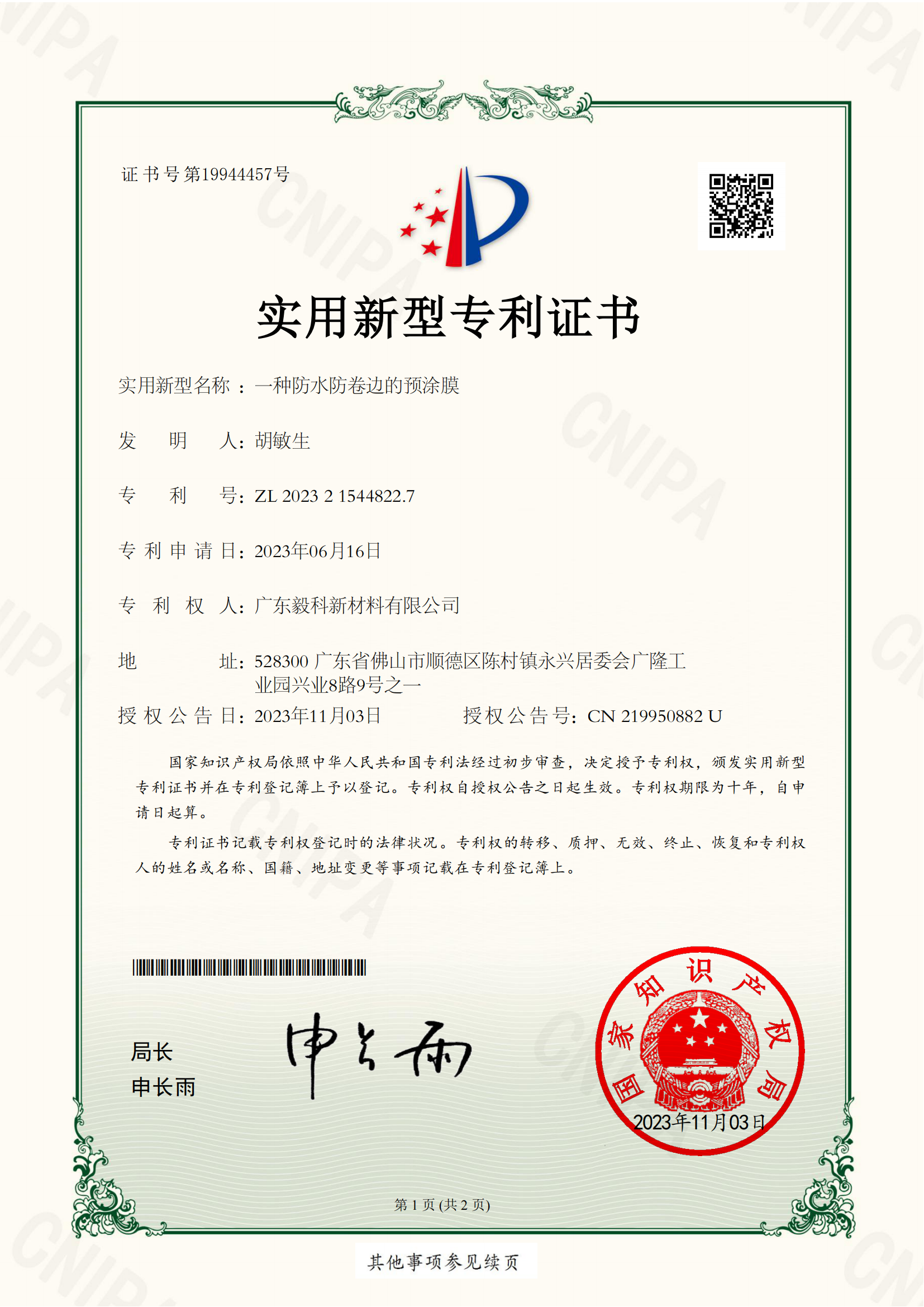

Deep Cooperation with School's Research Department Delivering Customized Solution

Compliance:

RoHS & REACH & Food Contact Material Triple-Certified

Packaging & Shipping:

FAQ:

Q1:Are you a factory or a trading company?

A: We are a company integrating R&D, production and sales.

Q2: How do you ensure the quality of your products?

A: We do end-to-end quality control-real time thickness check, corona value detection, bond strength testing, performance packaging.

Q3: What is your main products?

A: EKO has a broad product portfolio by catering to a wide range of industry needs, including BOPP thermal lamination film, digital super sticky thermal lamination film, thermal lamination film for inkjet printing, digital toner foil, DTF film & paper, heat sealable film, etc..

Q4: Can I get some samples or trial order for trying?

A: Yes, we provide free samples, the sample size is 320mm*30m per roll. You only need to pay for the shipping cost.

Q5: What services can we get?

A: We provide end-to-end customer support including professional customer service, customized solution, free samples, trial order, product information pack, technical consulting, full logistics tracking and feedback, comprehensive customer complaint process.

Q6: What payment terms do you offer?

A: We offer EXW, FOB, CIF, DAP, DDP, etc..