PET Metalized Thermal Lamination Film

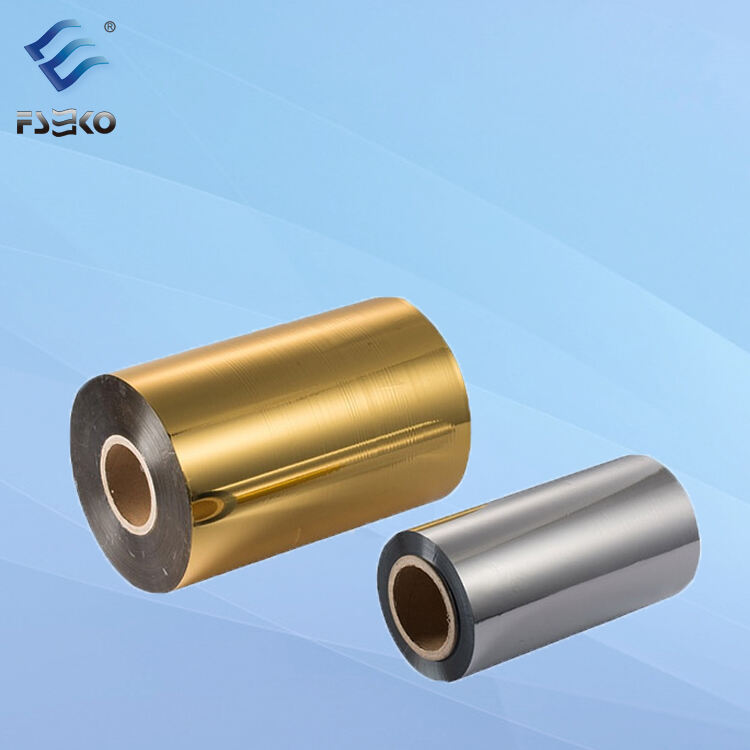

- Product name: PET metalized thermal lamination film

- Adhesive: EVA

- Surface: Glossy

- Color: Gold, silver

- Thickness: 22mic

- Width: 300mm~1500mm

- Overview

- Specification

- Advantages

- End-To-End Customer Support

- After-sales Service

- Recommended Products

Product description:

PET metalized thermal lamination film is a composite film. It uses PET film as the base material. An aluminum metal layer is formed on the PET surface through a vacuum-metalizing process.

PET is a thermoplastic polyester with excellent mechanical properties, transparency, chemical stability, and barrier properties. The metalized layer is mainly to endow the film with some special properties, such as high gloss, good barrier properties (especially against oxygen and water vapor), and electromagnetic shielding properties.

Specification:

|

Product name |

PET metalized thermal lamination film |

|

Adhesive |

EVA |

|

Surface |

Glossy |

|

Color |

Gold, silver |

|

Thickness |

22mic |

|

Width |

300mm~1500mm |

|

Length |

200m~4000m |

|

Core |

1 inch(25.4mm)/3 inch(76.2mm) |

|

Packaging |

Top and bottom box/Carton box |

|

Laminating temp. |

110℃~120℃ |

|

Place of origin |

Guangdong, China |

Advantages:

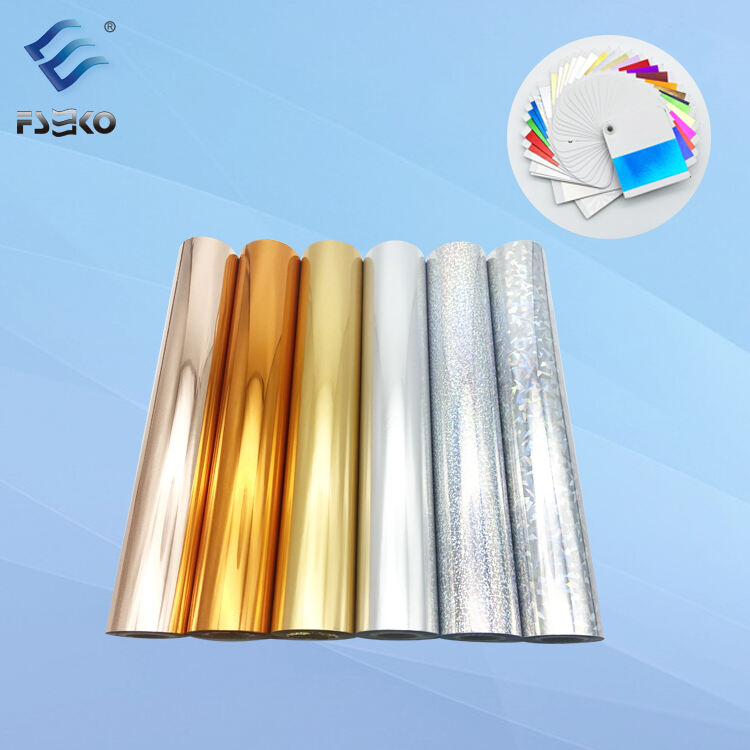

- Aesthetics:

PET metalized thermal lamination film has a shiny, metallic appearance that can be used to create attractive and eye-catching packaging designs. It is commonly used in the production of labels, packaging boxes, and decorative laminates to make products stand out on the shelves and attract consumers' attention. For instance, it is often used in the packaging of cosmetics, chocolates, and luxury goods.

- Can Be Post Processing:

PET metalized thermal lamination film supports post-processing to meet the requirements of different application scenarios, such as printing, hot stamping, embossing, etc.

End-To-End Customer Support:

Customized Film Solutions:

Solve Your Specific Pain Points

Edge warping of heat-intolerant printing materials after laminating

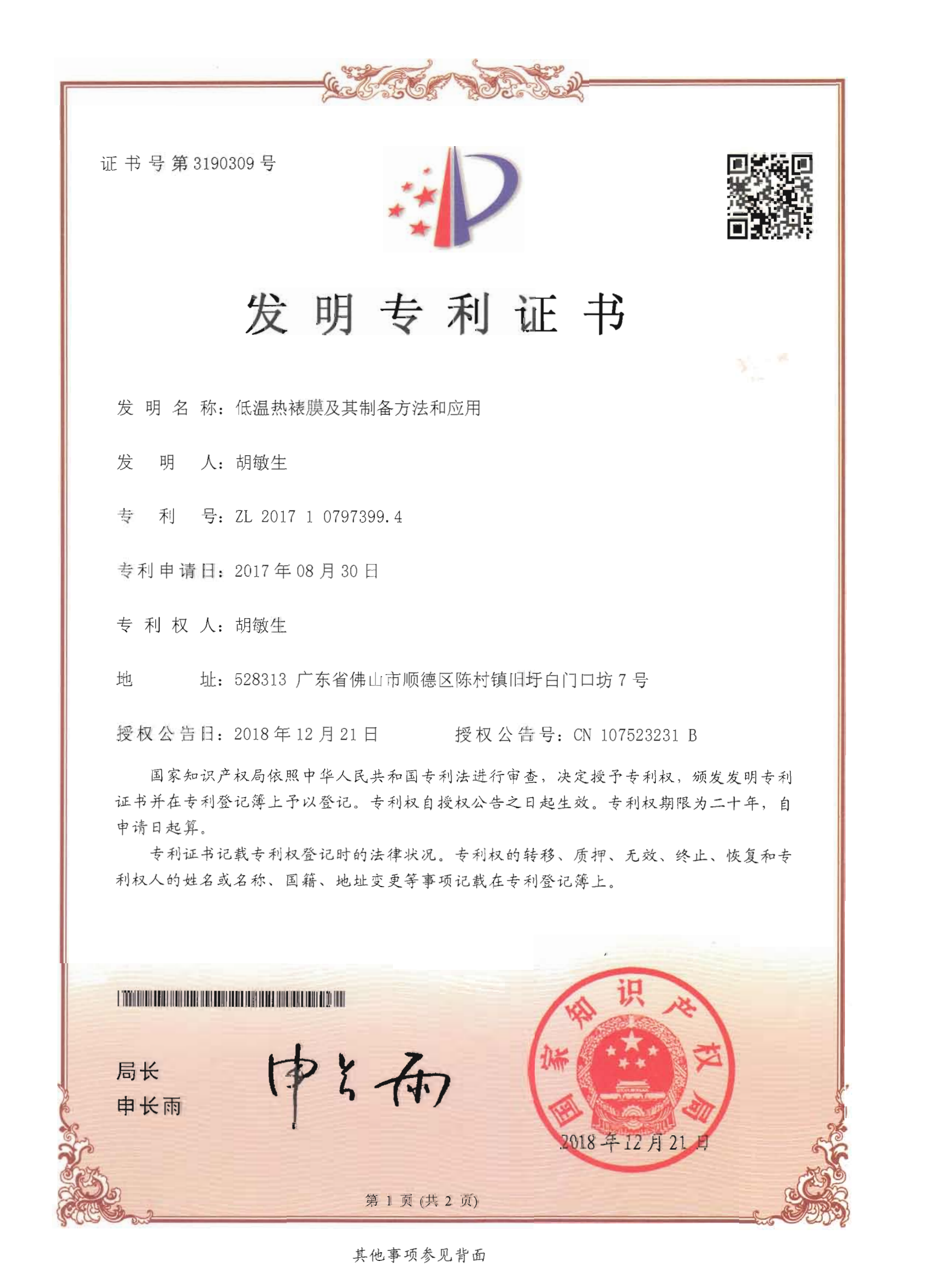

SOLUTION:LowTemperature Thermal Lamination Film

Delamination of digital toner printings after laminating

SOLUTION:Digital Thermal Lamination Film

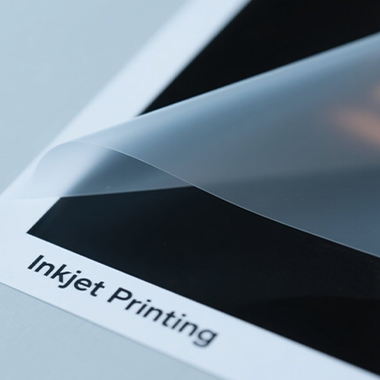

Low adhesive of inkjet printings after laminating

SOLUTION:Thermal Lamination Film for Inkjet Printing

Solution:

Deep Cooperation with School's Research Department Delivering Customized Solution

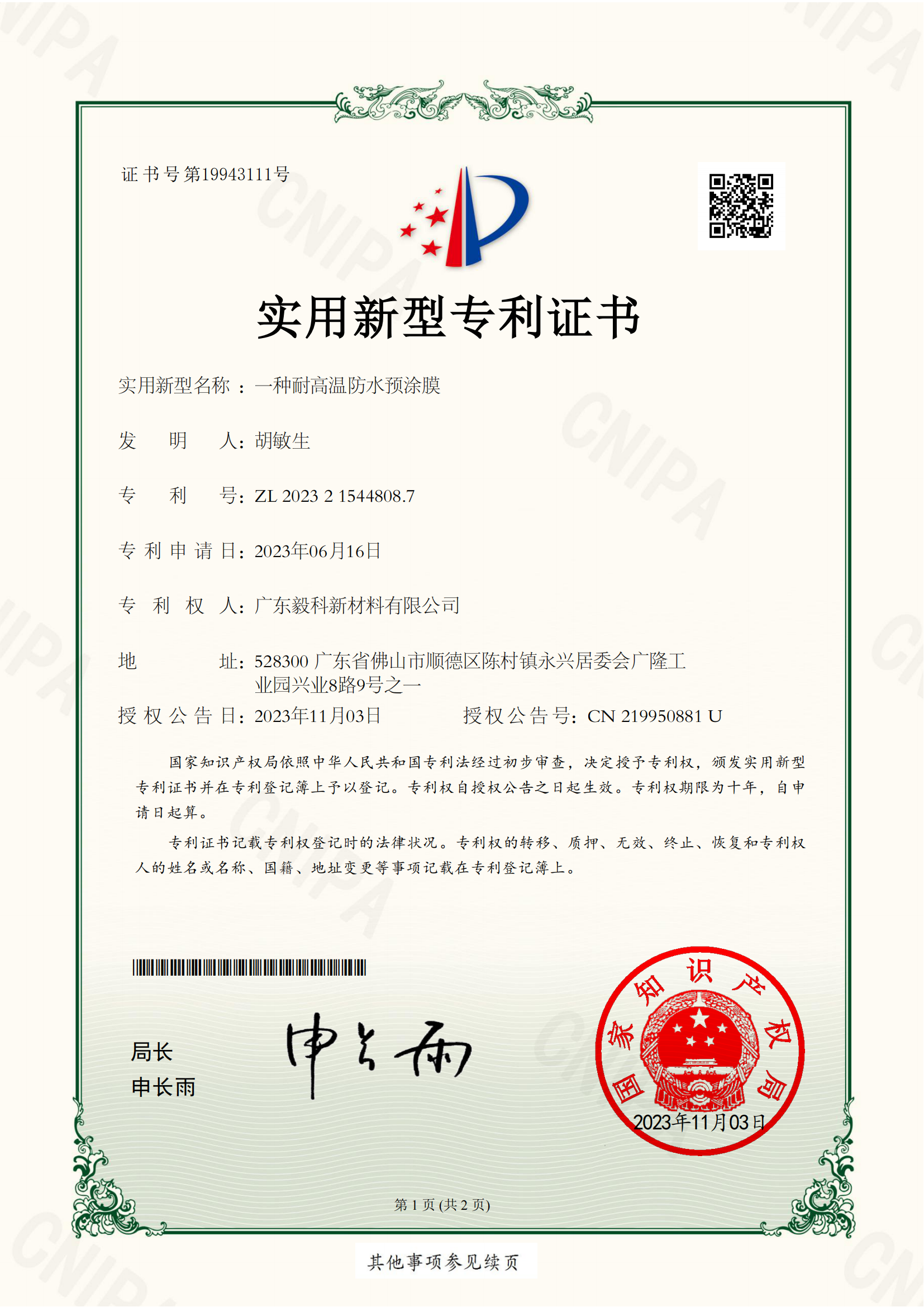

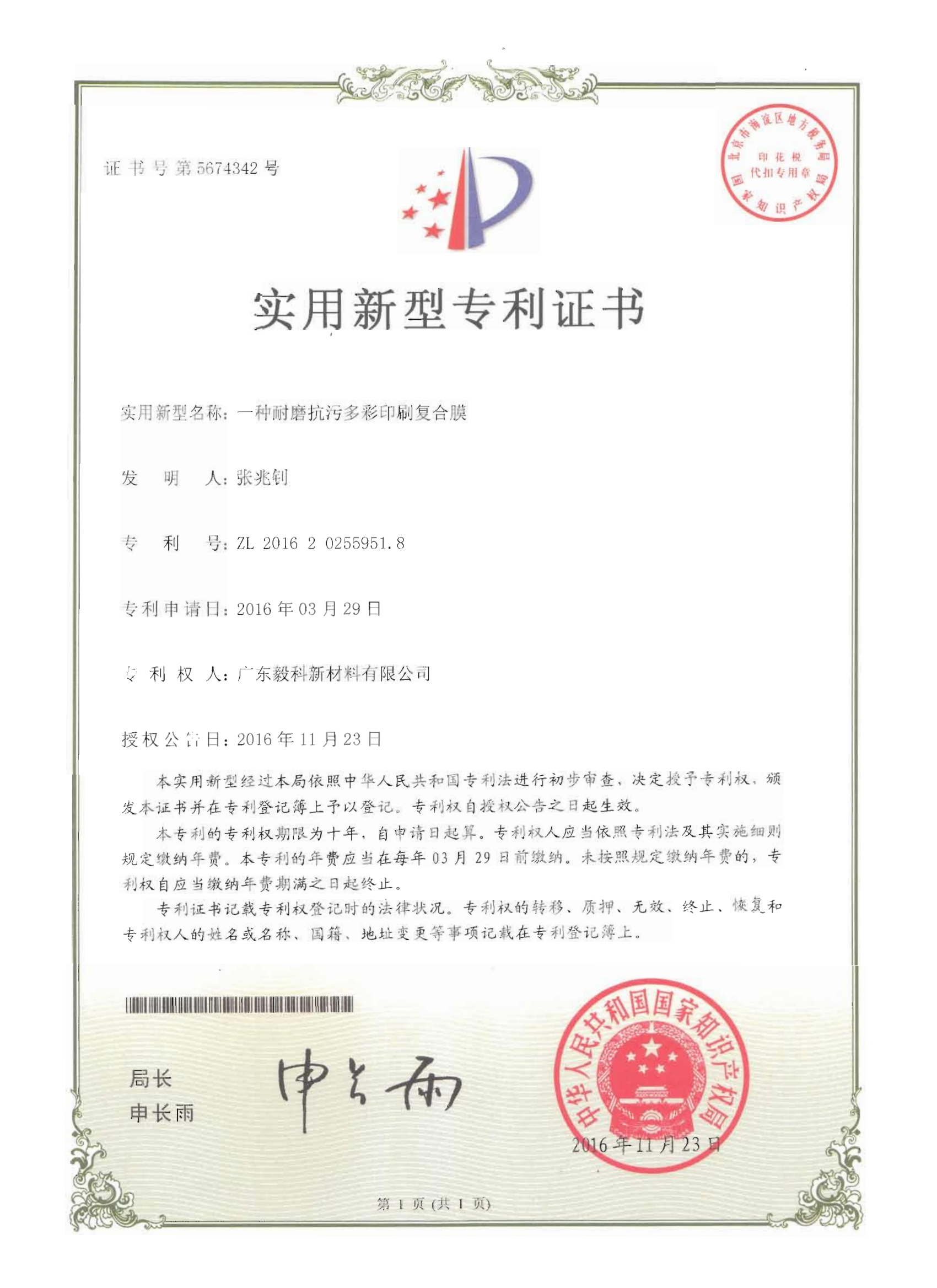

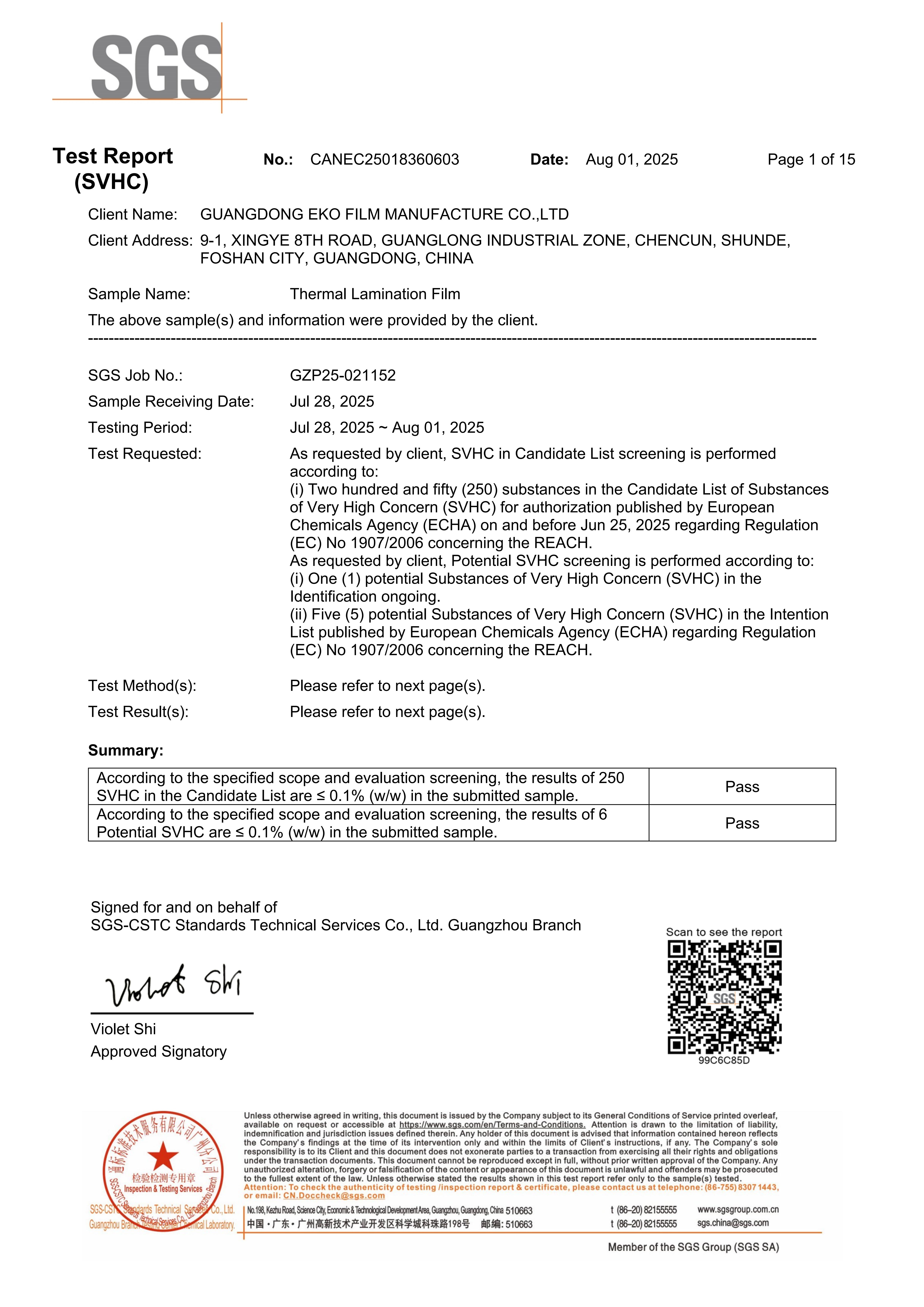

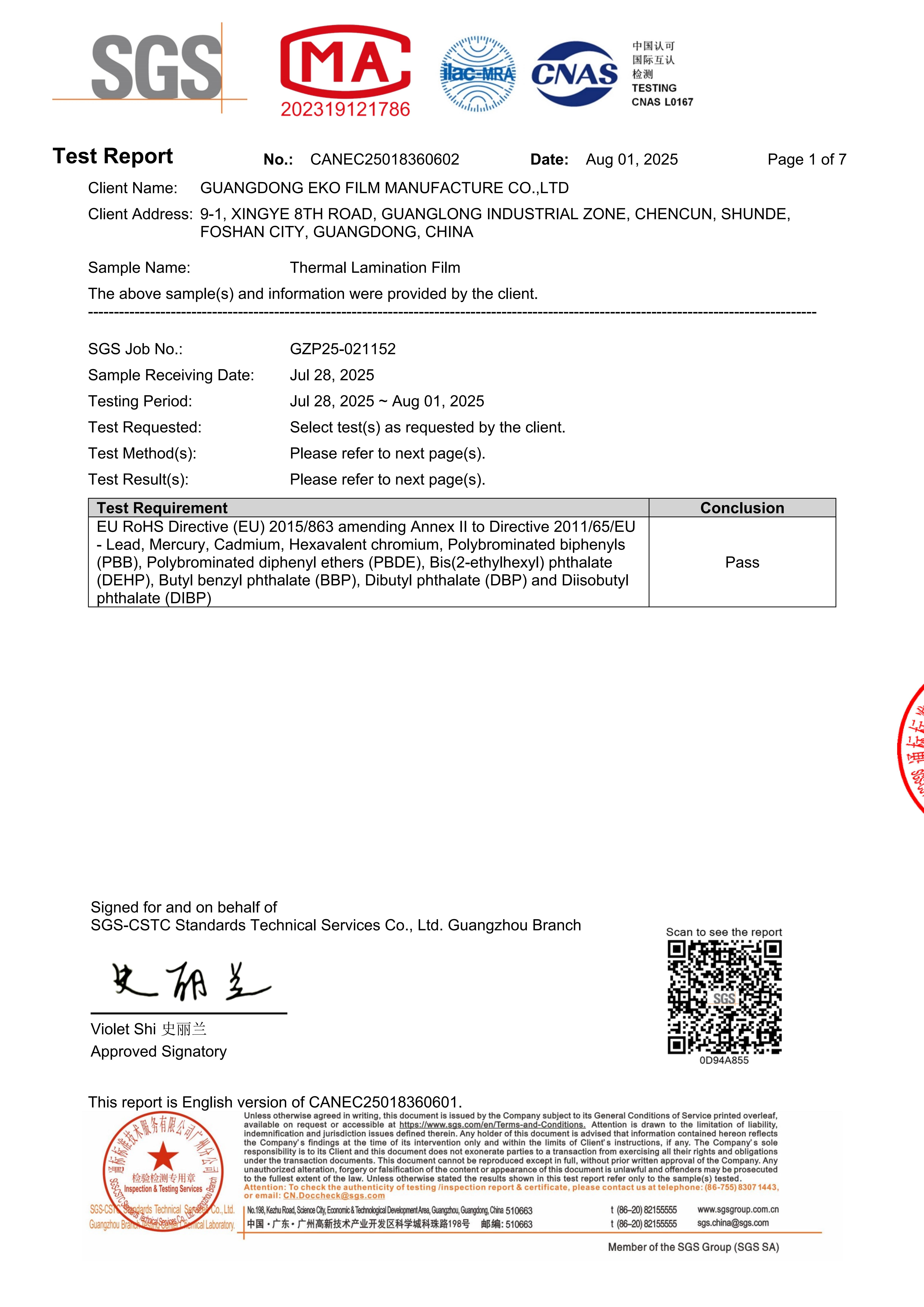

Compliance:

RoHS & REACH & Food Contact Material Triple-Certified

Packaging & Shipping:

FAQ:

Q1:Are you a factory or a trading company?

A: We are a company integrating R&D, production and sales.

Q2: How do you ensure the quality of your products?

A: We do end-to-end quality control-real time thickness check, corona value detection, bond strength testing, performance packaging.

Q3: What is your main products?

A: EKO has a broad product portfolio by catering to a wide range of industry needs, including BOPP thermal lamination film, digital super sticky thermal lamination film, thermal lamination film for inkjet printing, digital toner foil, DTF film & paper, heat sealable film, etc..

Q4: Can I get some samples or trial order for trying?

A: Yes, we provide free samples, the sample size is 320mm*30m per roll. You only need to pay for the shipping cost.

Q5: What services can we get?

A: We provide end-to-end customer support including professional customer service, customized solution, free samples, trial order, product information pack, technical consulting, full logistics tracking and feedback, comprehensive customer complaint process.

Q6: What payment terms do you offer?

A: We offer EXW, FOB, CIF, DAP, DDP, etc..