Plastic-Free Thermal Lamination Film

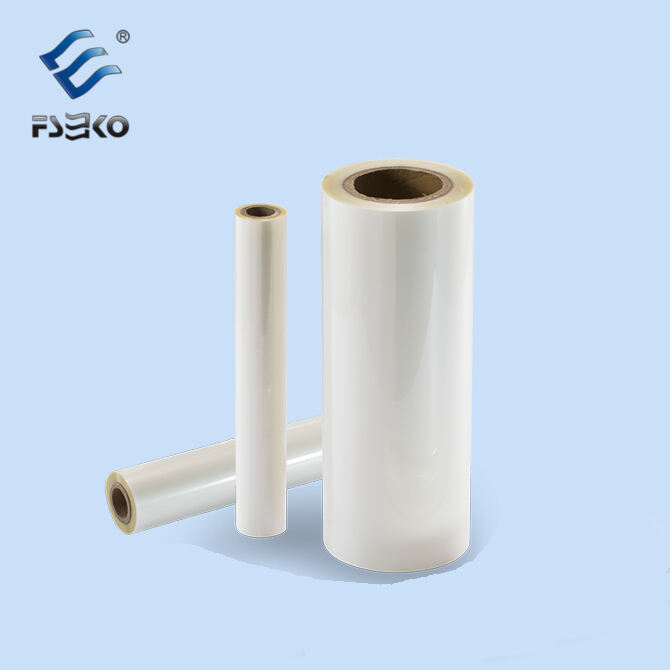

- Product name: Plastic-Free Thermal Lamination Film

- Adhesive: EVA

- Surface: Matt

- Thickness: 25mic

- Width: 300mm~1890mm

- Length: 200m~4000m

- Overview

- Specification

- Advantages

- End-To-End Customer Support

- After-sales Service

- Recommended Products

Product description:

Plastic-free thermal lamination film represents an innovative and environmentally responsible alternative to conventional plastic-based laminating film. It is designed with a unique dual-layer structure: a recyclable BOPP base film and a specially formulated plastic-free coating. This combination delivers reliable printing protection and finishing performance while significantly reducing environmental impact. After use, the BOPP film can be separated and recycled, while the biodegradable coating dissolves during paper repulping, supporting a circular economy and minimizing waste.

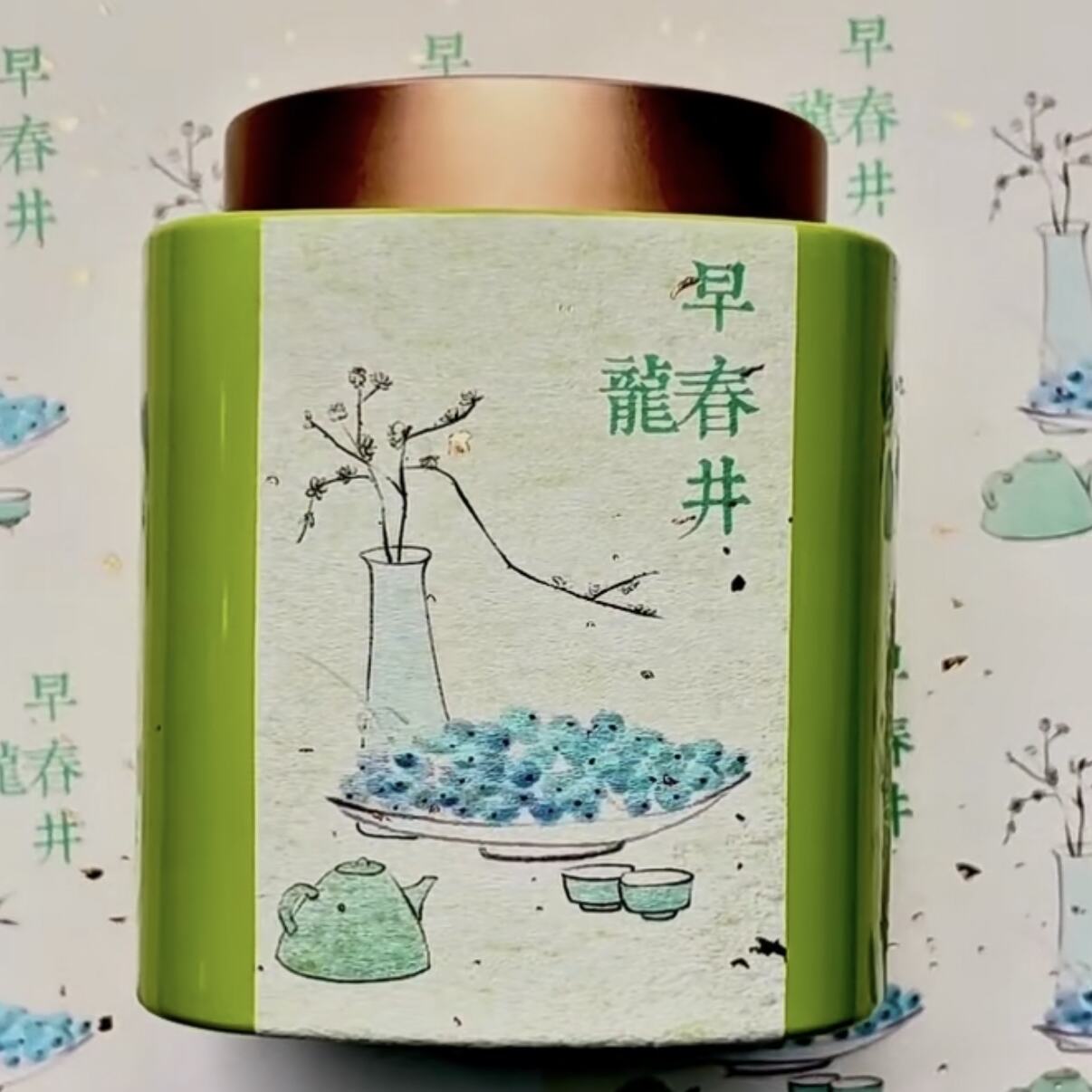

Project Showcase:

TicketLabel Hangtag Greeting Card

Gift BoxCalenderBrochureBox

Specification:

|

Product name |

Plastic-Free Thermal Lamination Film |

|

Adhesive |

EVA |

|

Surface |

Matt |

|

Thickness |

25mic |

|

Width |

300mm~1890mm |

|

Length |

200m~4000m |

|

Core |

1 inch(25.4mm)/3 inch(76.2mm) |

|

Packaging |

Top and bottom box/Carton box |

|

Laminating temp. |

105℃~120℃ |

|

Place of Origin |

Guangdong, China |

Advantages:

- Reduced Environmental Footprint:

Significantly lowers plastic waste and pollution by utilizing a separable and recyclable BOPP base combined with a biodegradable top coating.

- Recyclable BOPP Base Film:

The BOPP carrier film can be easily peeled off after use and recycled into new plastic products, supporting resource efficiency and circular material flows.

- Supports Brand Sustainability Goals:

Ideal for businesses aiming to reduce plastic usage, improve recyclability, and meet consumer demand for eco-friendly products.

End-To-End Customer Support:

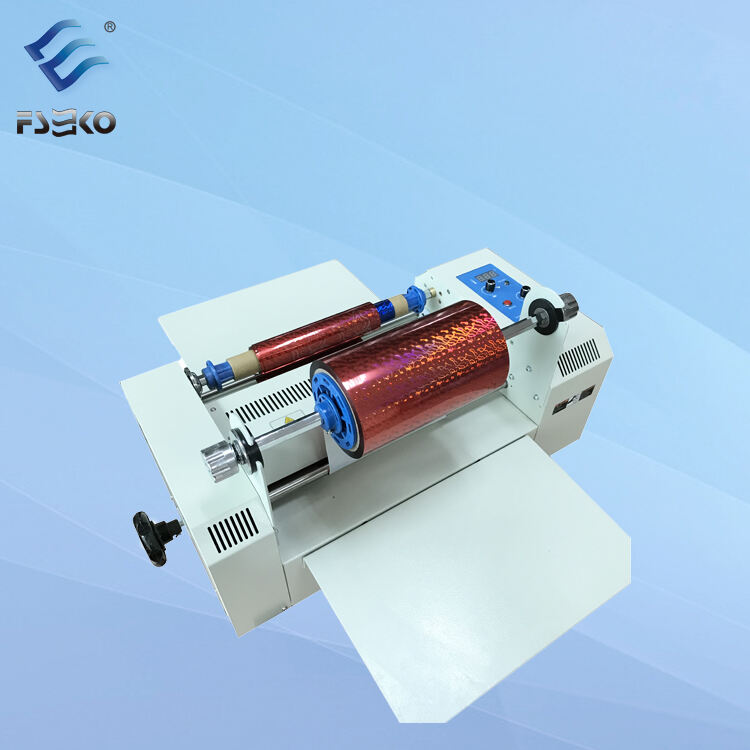

Customized Film Solutions:

Solve Your Specific Pain Points

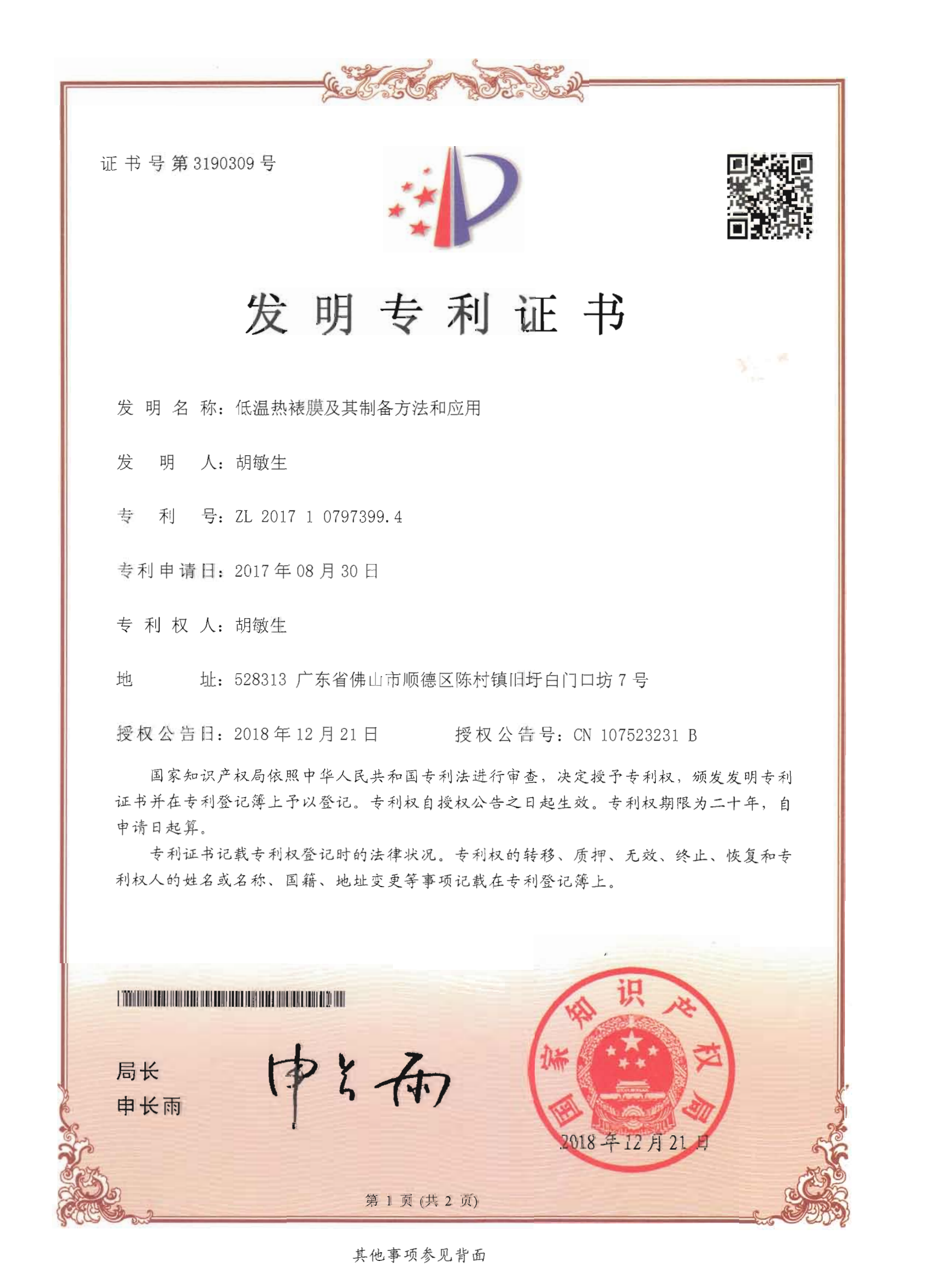

Edge warping of heat-intolerant printing materials after laminating

SOLUTION:LowTemperature Thermal Lamination Film

Delamination of digital toner printings after laminating

SOLUTION:Digital Thermal Lamination Film

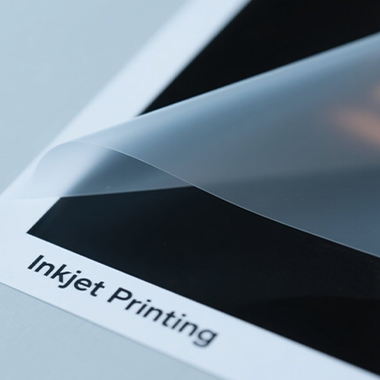

Low adhesive of inkjet printings after laminating

SOLUTION:Thermal Lamination Film for Inkjet Printing

Solution:

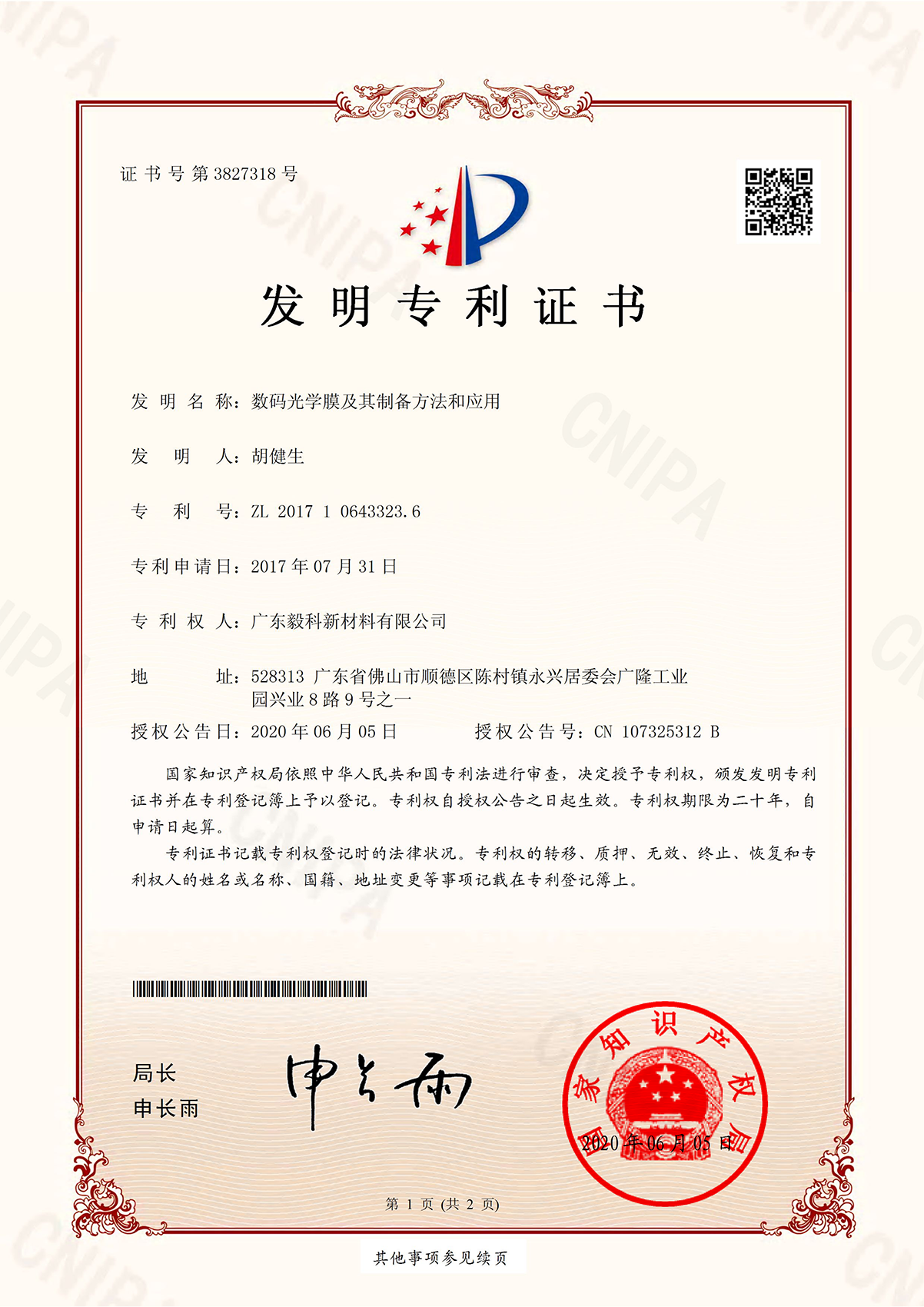

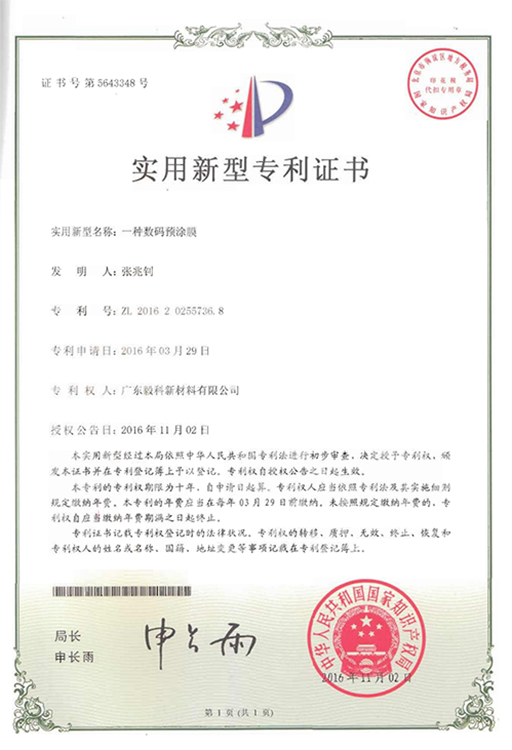

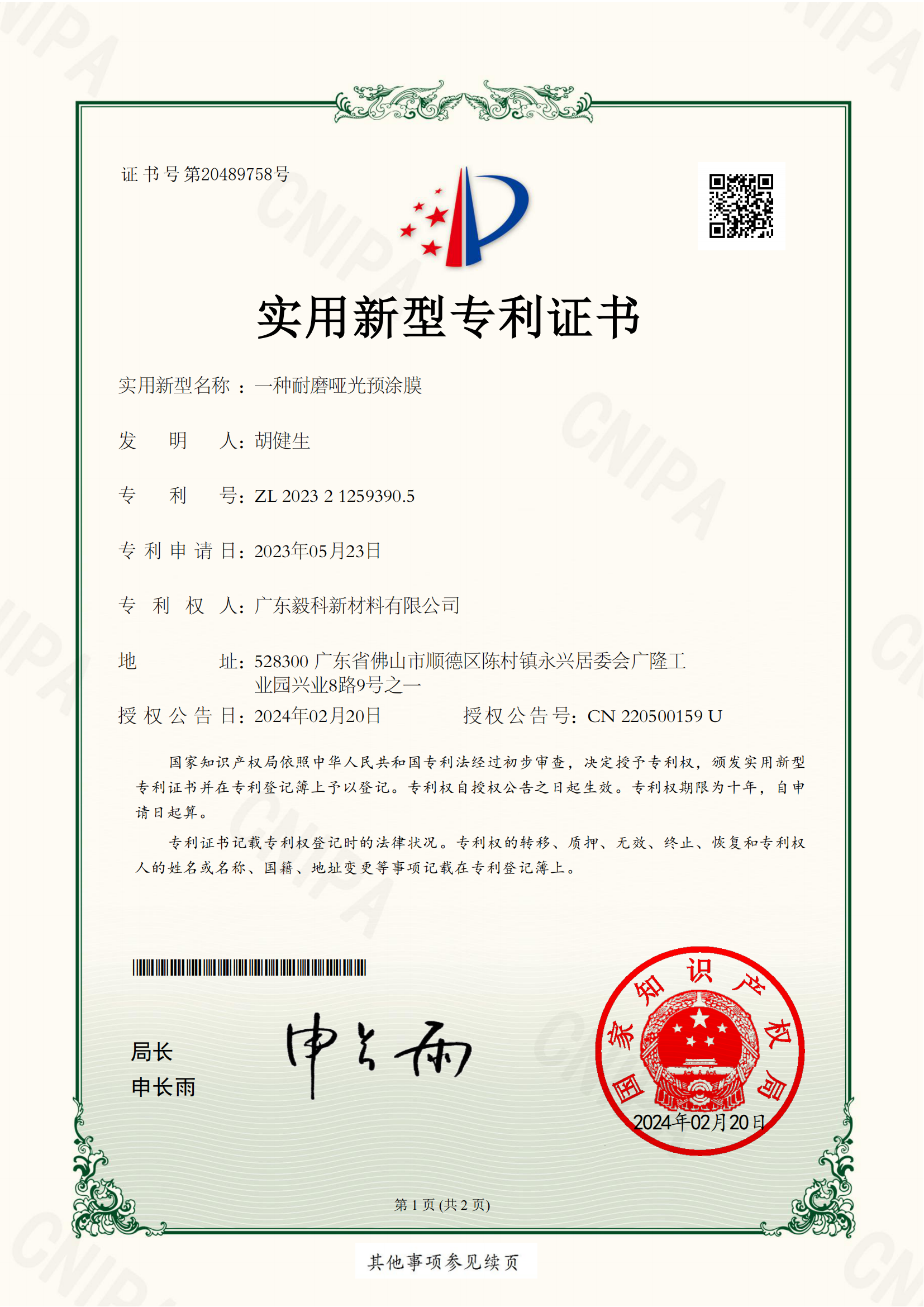

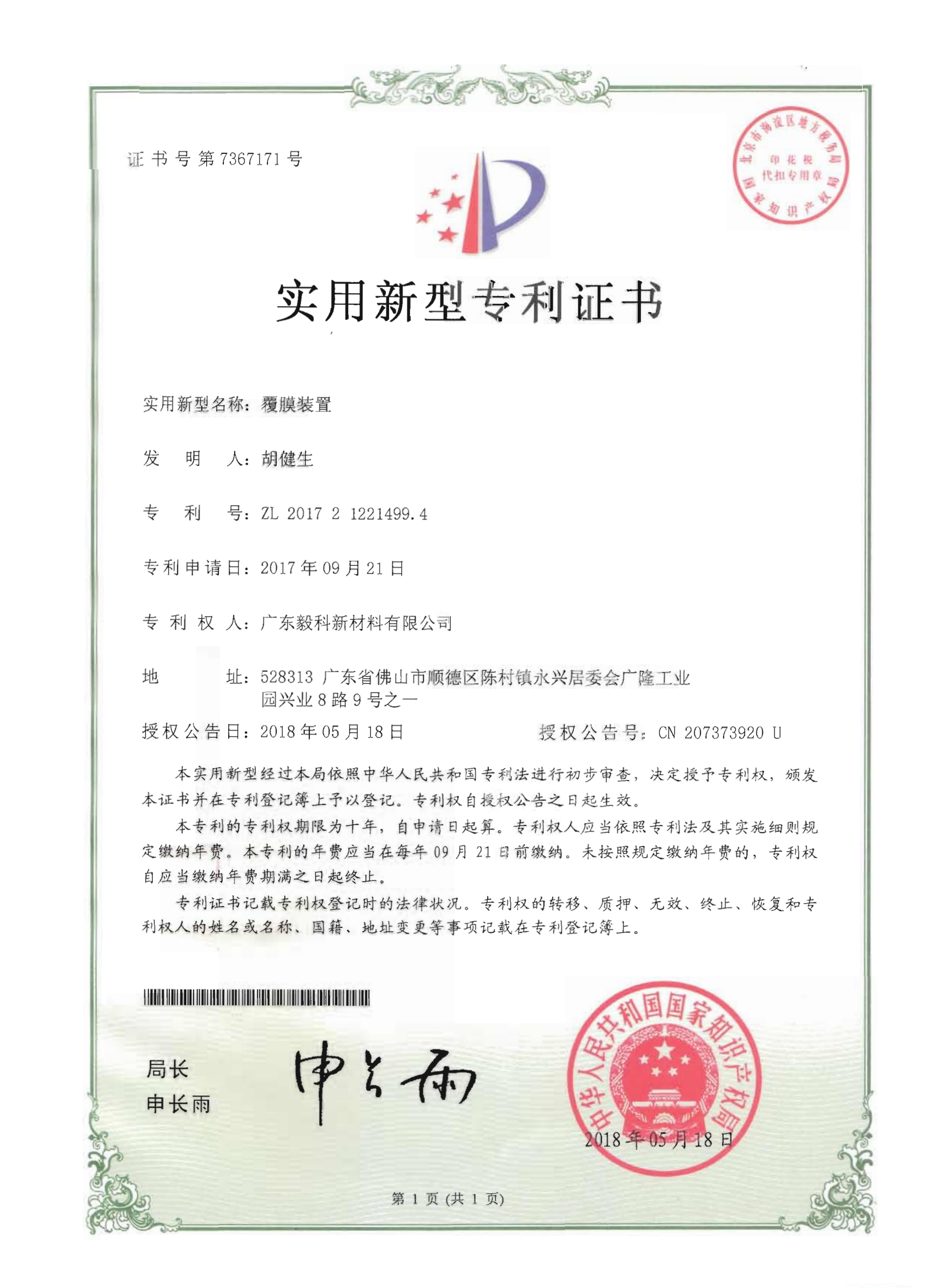

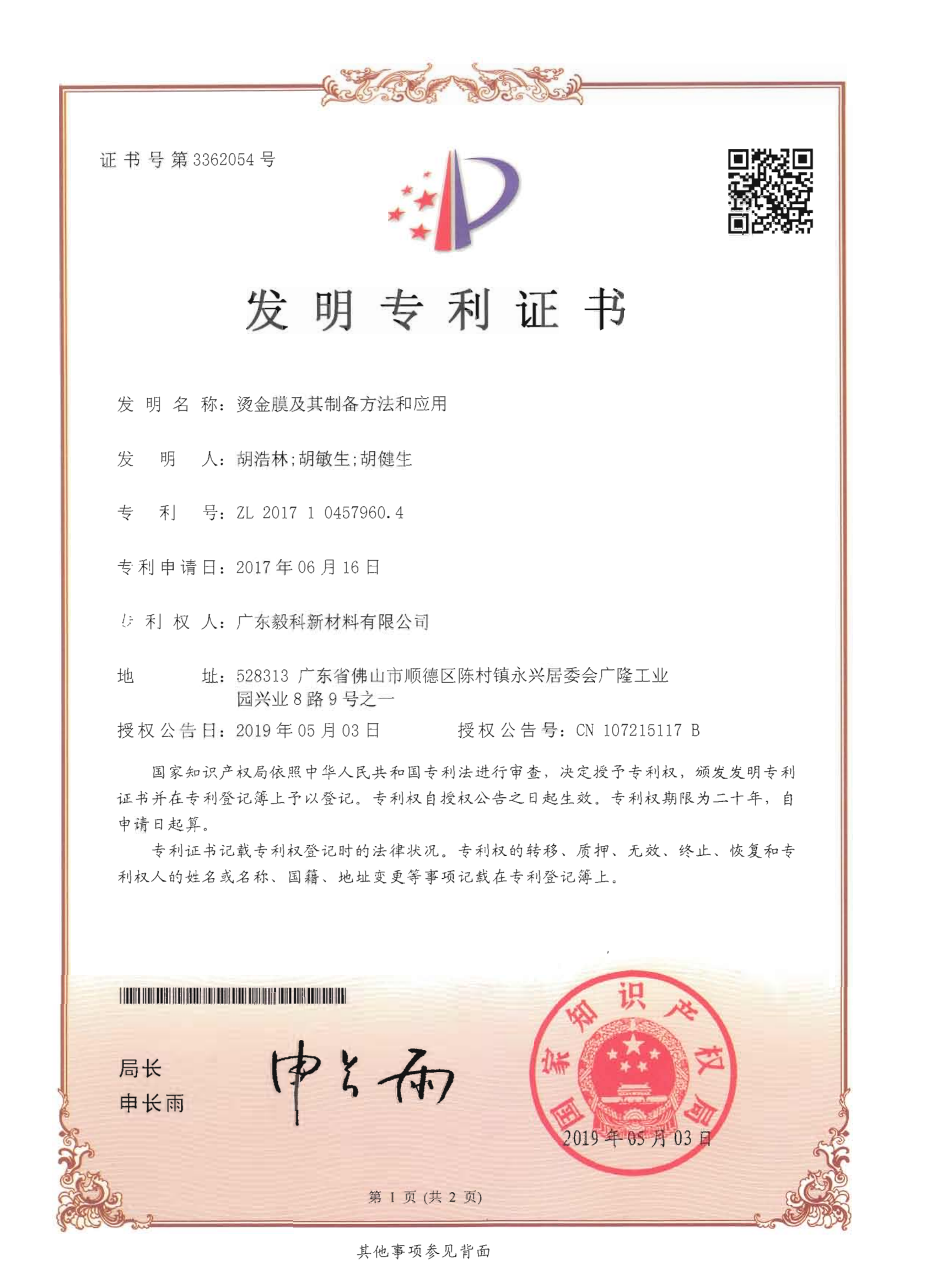

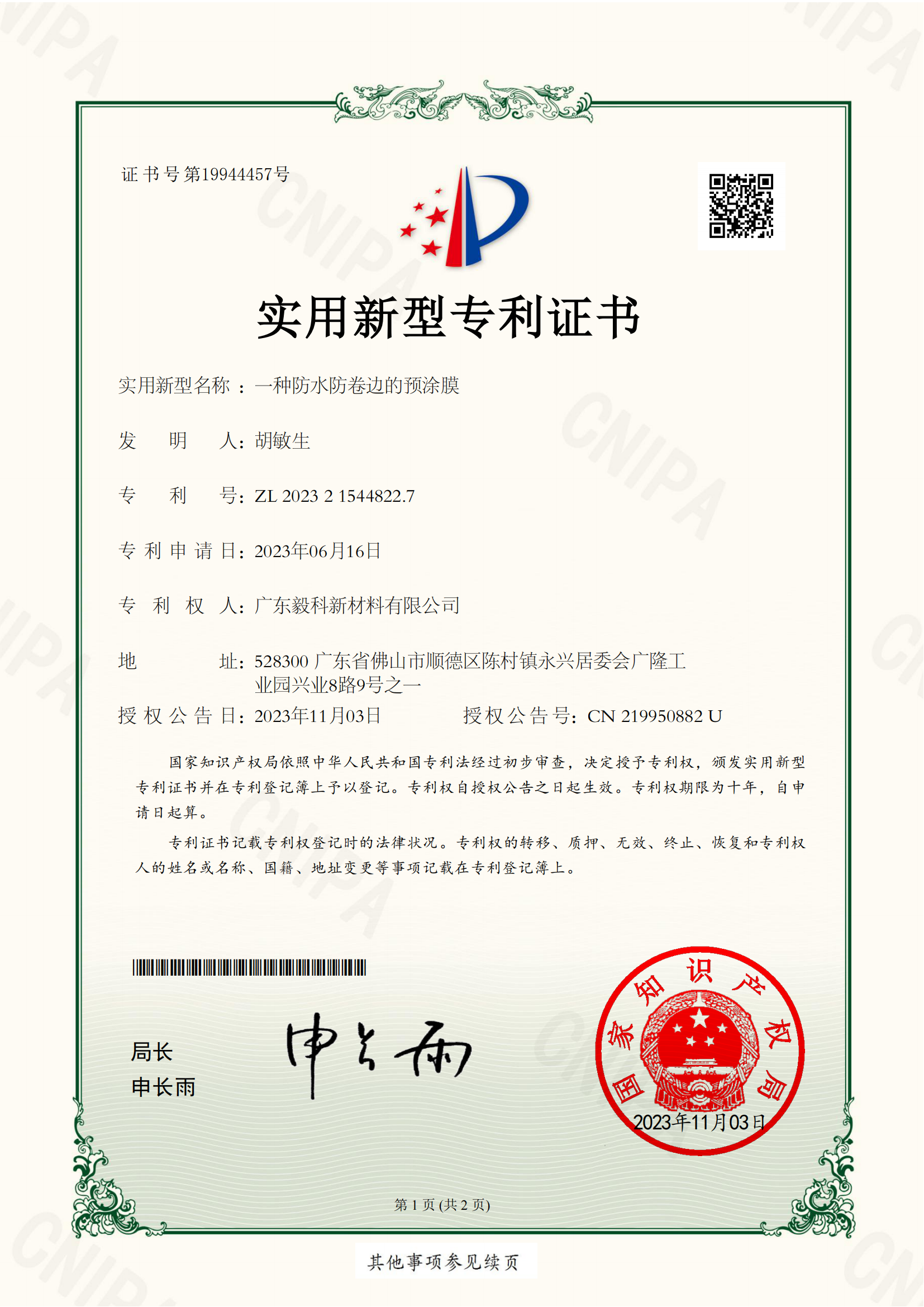

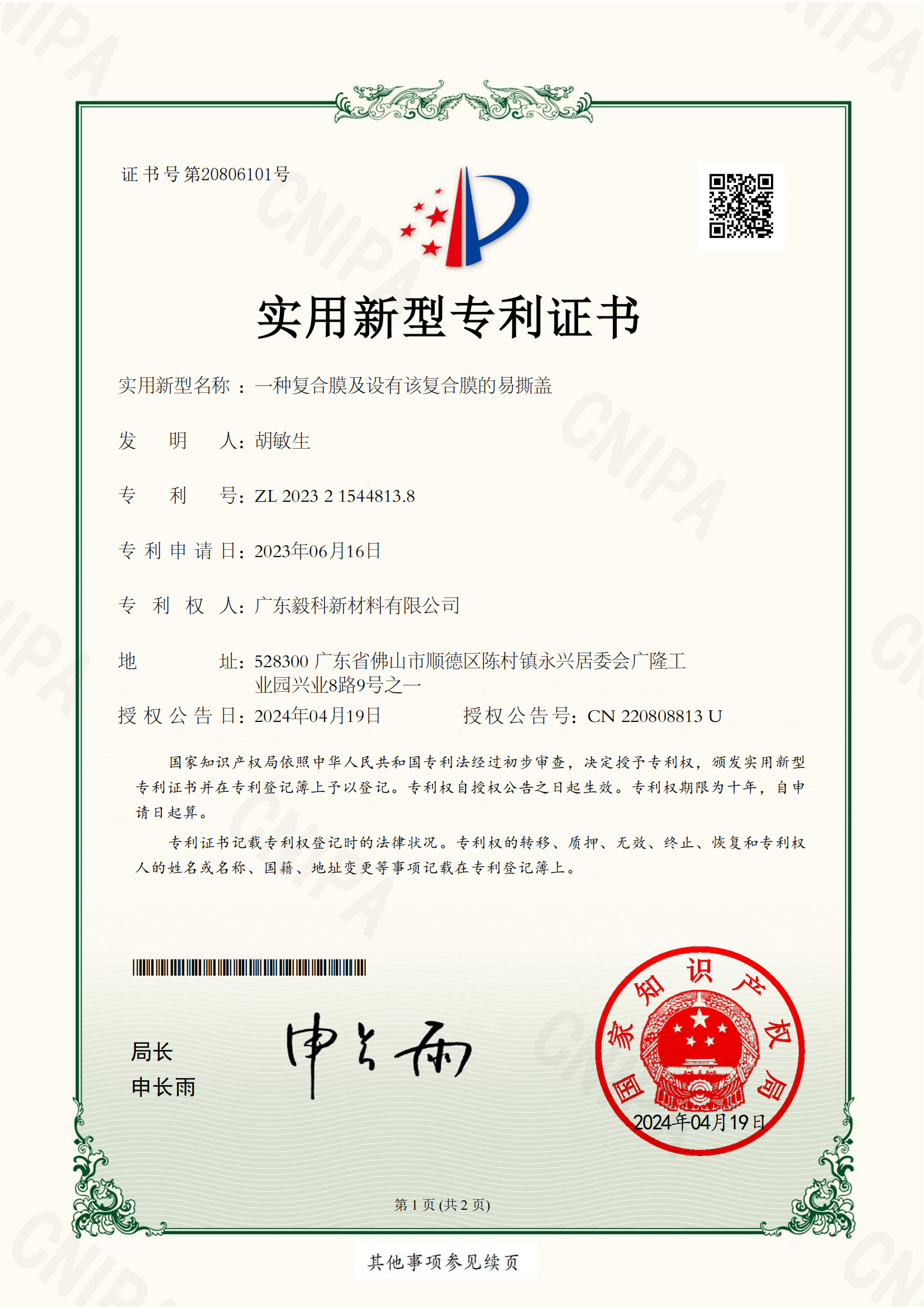

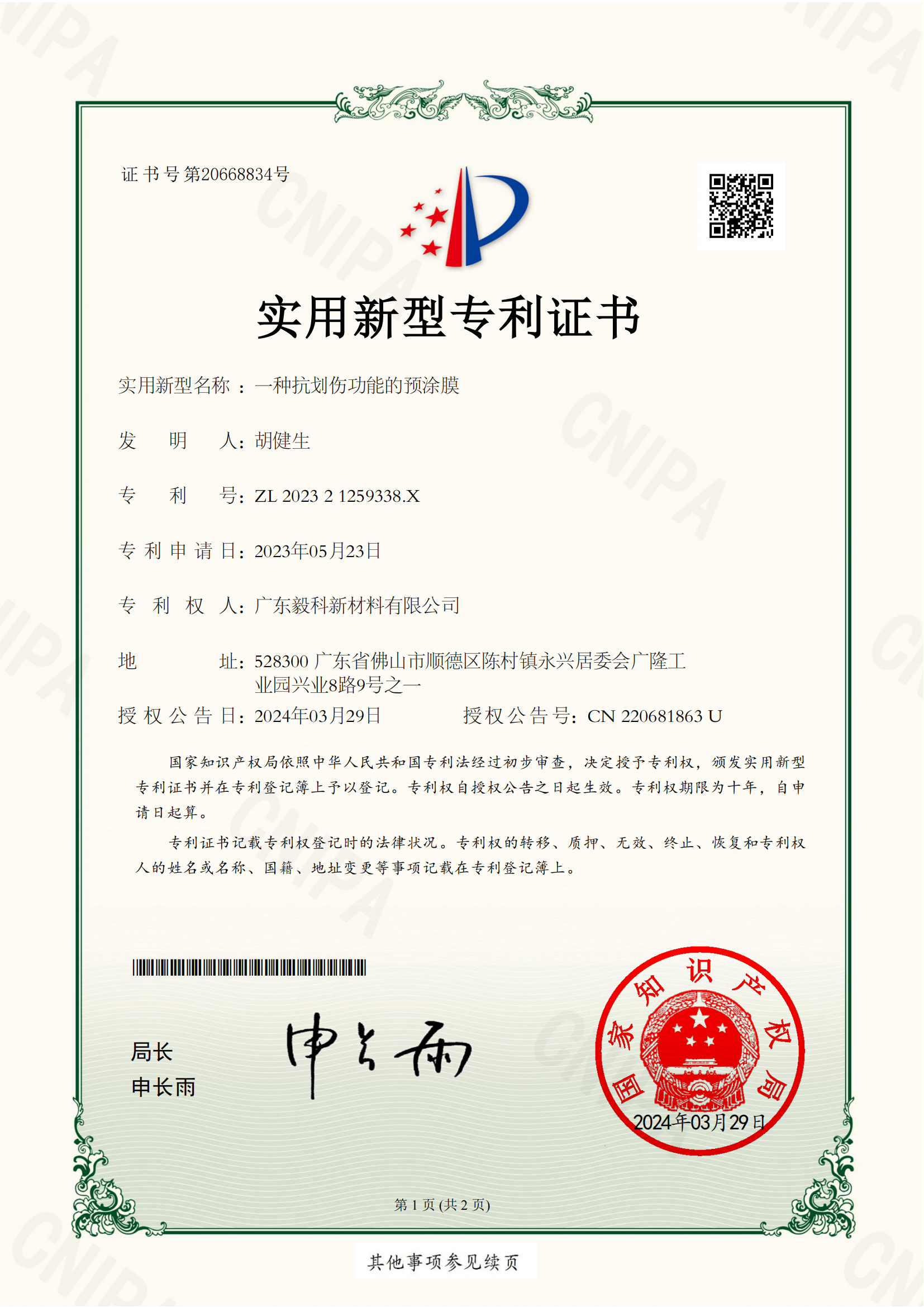

Deep Cooperation with School's Research Department Delivering Customized Solution

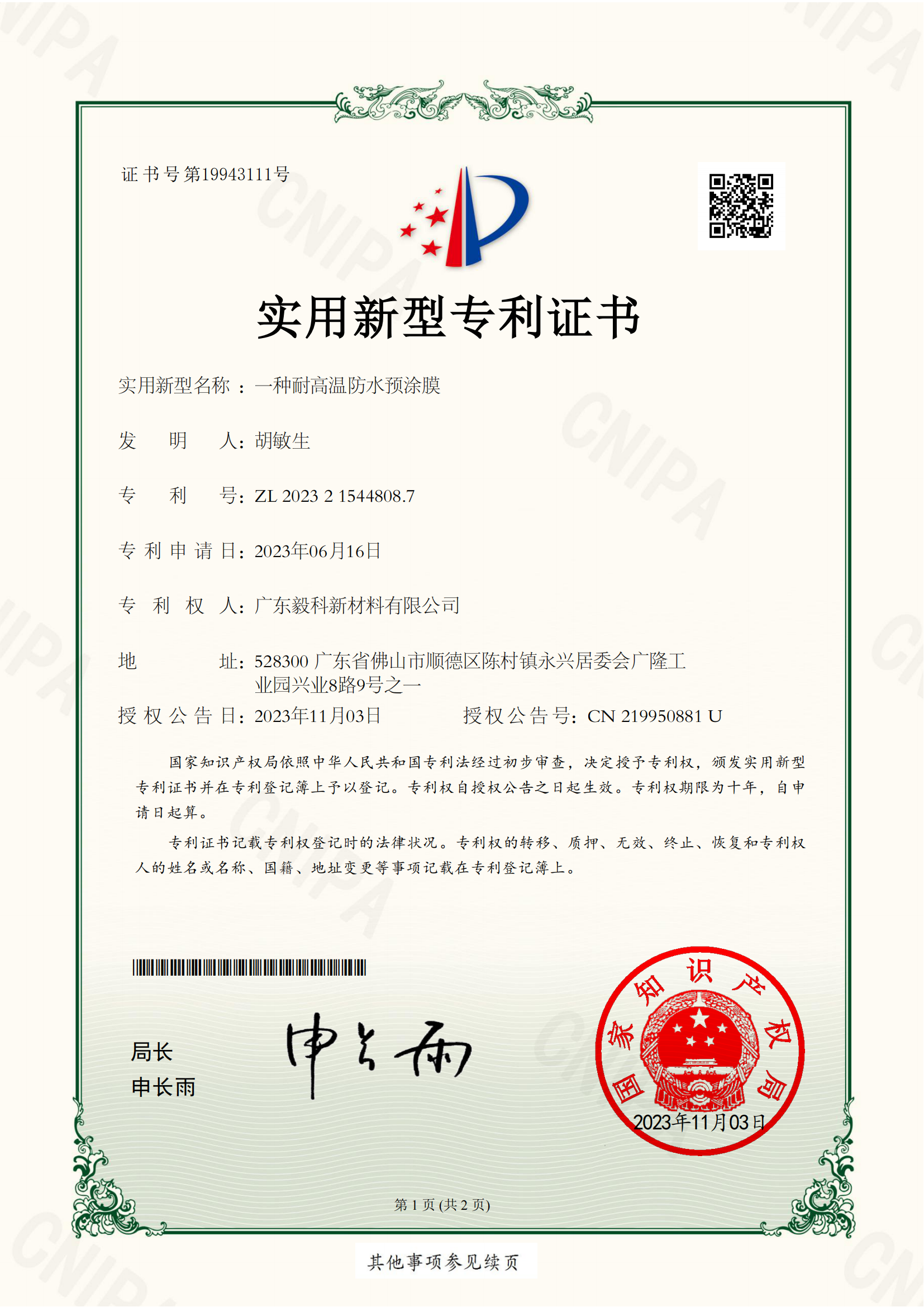

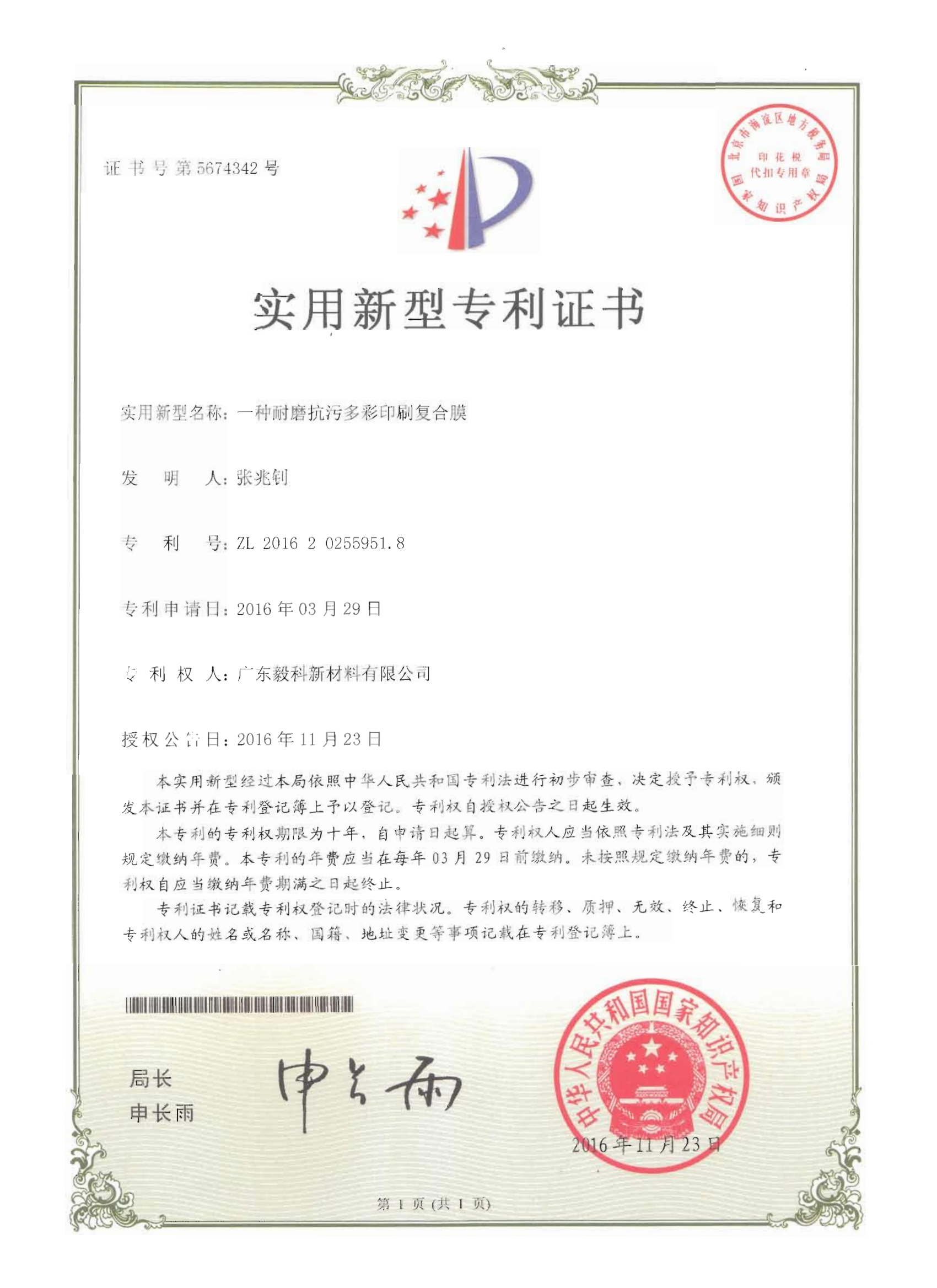

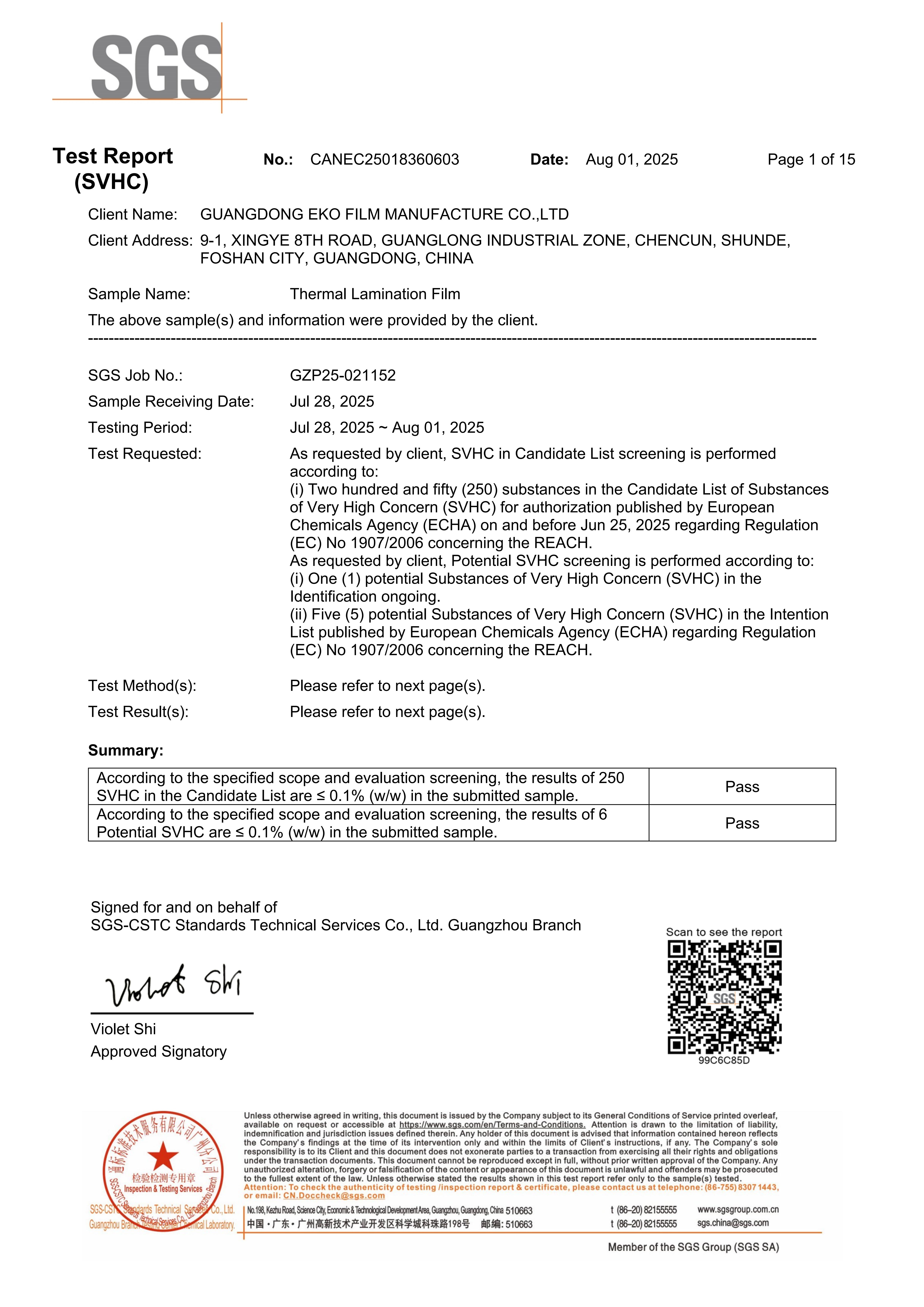

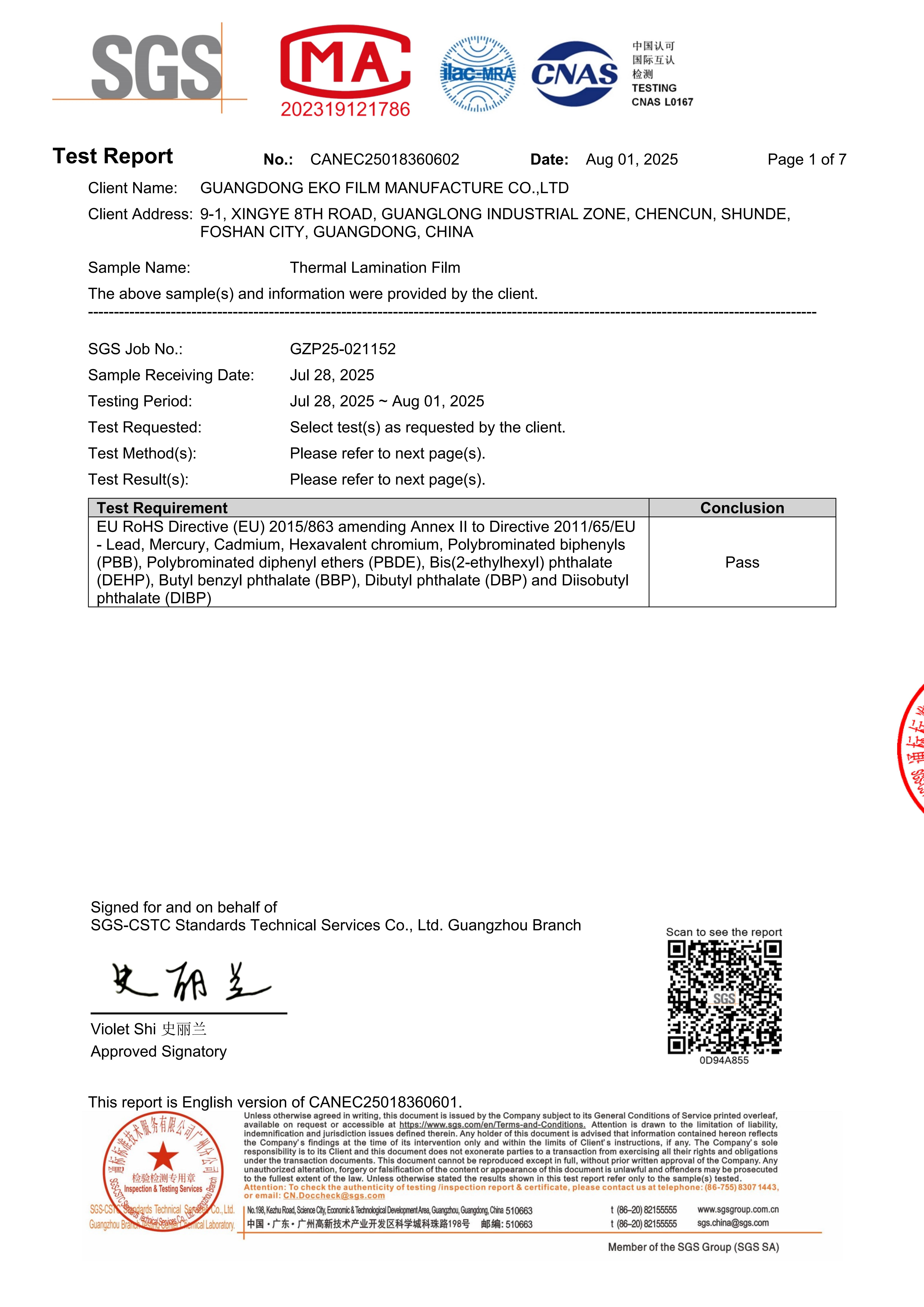

Compliance:

RoHS & REACH & Food Contact Material Triple-Certified

Packaging & Shipping:

FAQ:

Q1:Are you a factory or a trading company?

A: We are a company integrating R&D, production and sales.

Q2: How do you ensure the quality of your products?

A: We do end-to-end quality control-real time thickness check, corona value detection, bond strength testing, performance packaging.

Q3: What is your main products?

A: EKO has a broad product portfolio by catering to a wide range of industry needs, including BOPP thermal lamination film, digital super sticky thermal lamination film, thermal lamination film for inkjet printing, digital toner foil, DTF film & paper, heat sealable film, etc..

Q4: Can I get some samples or trial order for trying?

A: Yes, we provide free samples, the sample size is 320mm*30m per roll. You only need to pay for the shipping cost.

Q5: What services can we get?

A: We provide end-to-end customer support including professional customer service, customized solution, free samples, trial order, product information pack, technical consulting, full logistics tracking and feedback, comprehensive customer complaint process.

Q6: What payment terms do you offer?

A: We offer EXW, FOB, CIF, DAP, DDP, etc..