PET Thermal Lamination Matt Film

- Product name: PET thermal lamination film

- Adhesive: EVA

- Surface: Matt

- Thickness: 21mic~75mic

- Width: 300mm~1890mm

- Length: 200m~4000m

- Overview

- Specification

- Advantages

- End-To-End Customer Support

- After-sales Service

- Recommended Products

Product description:

Thermal lamination film is a widely used plastic film in the packaging and printing industries. It is designed to bond with other materials through the application of heat and pressure.

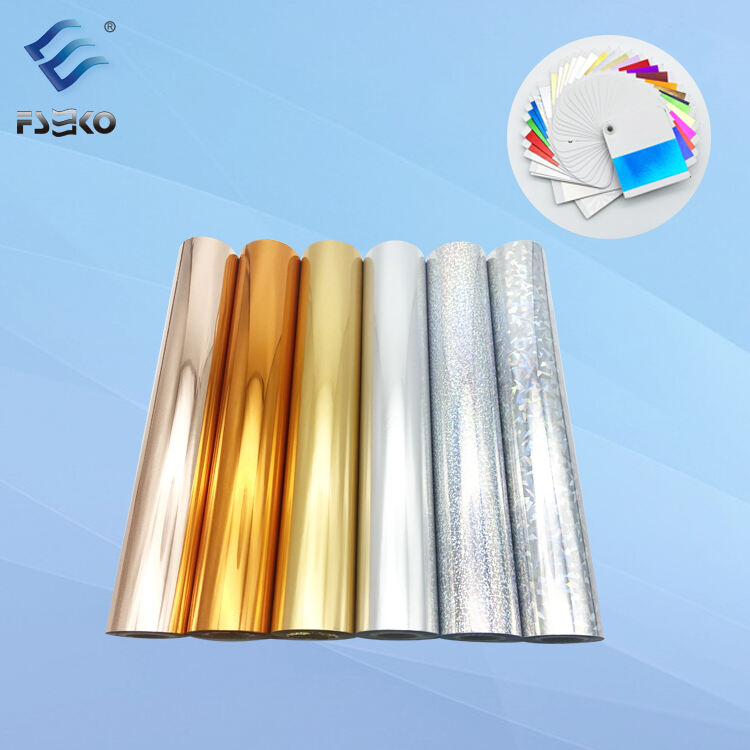

Common materials for pre-coated film includes BOPP, PET, PVC, CPP etc.. Surface treatment type can be glossy, matt, anti-scratch, soft touch, glitter...

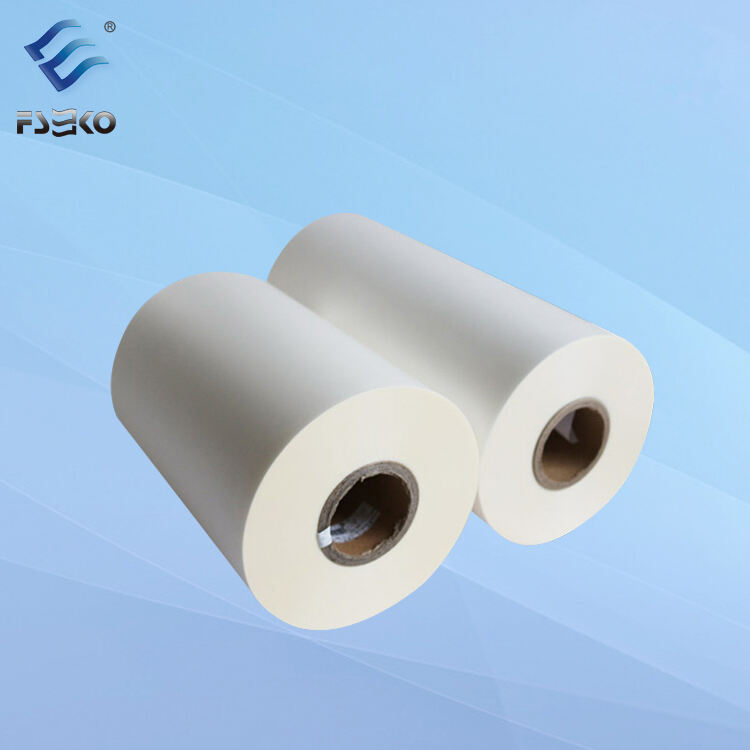

PET thermal lamination film consists of PET and EVA. PET, a polyester material, is known for its excellent mechanical, chemical resistance, and good barrier properties against moisture and gases. It also has high transparency and can withstand relatively high temperatures.

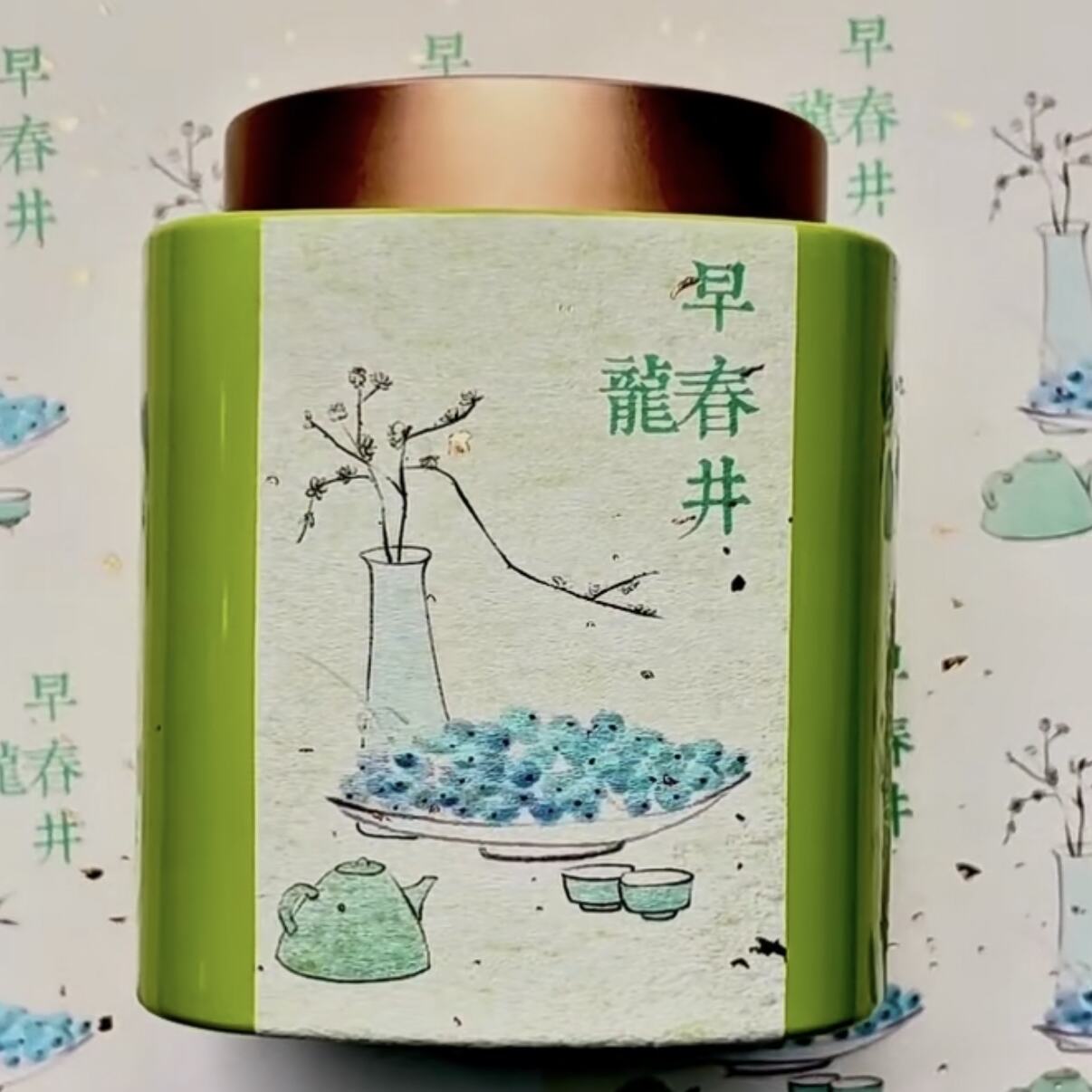

PET thermal lamination matt film gives a sophisticated and understated look to the laminated materials. It reduces glare, making it more comfortable for the eyes to view, especially in brightly lit environments.

Project Showcase:

TicketLabel Hangtag Greeting Card

Gift BoxCalenderBrochureBox

Specification:

|

Product name |

PET thermal lamination film |

|

Adhesive |

EVA |

|

Surface |

Matt |

|

Thickness |

21mic~75mic |

|

Width |

300mm~1890mm |

|

Length |

200m~4000m |

|

Core |

1 inch(25.4mm)/3 inch(76.2mm) |

|

Packaging |

Top and bottom box/Carton box |

|

Laminating temp. |

115℃~125℃ |

|

Place of Origin |

Guangdong, China |

Advantages:

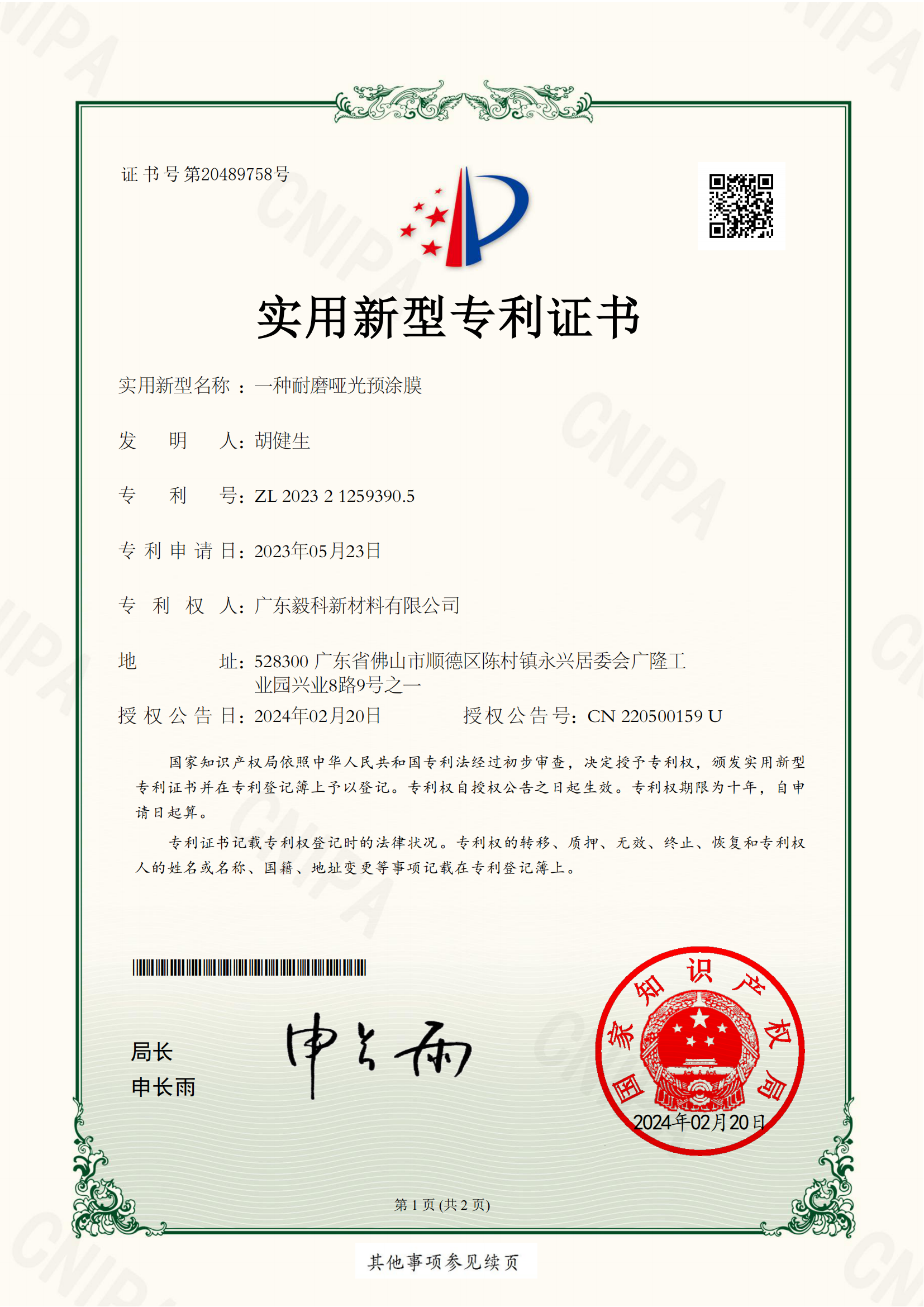

- Elegant Matte Appearance:

It provides a non-glossy, sophisticated finish that gives a refined and understated look to laminated items. This is highly desirable for applications where a more subdued aesthetic is preferred.

- Reduced Glare:

The matte surface scatters light, significantly reducing glare. This makes it easier on the eyes, especially in brightly lit environments, and allows for better viewing of the laminated content without the distraction of reflections.

- Moisture and Gas Barrier Properties:

It has excellent barrier properties against moisture, preventing water vapor from penetrating and potentially damaging the laminated item. Additionally, it provides some degree of gas barrier protection, reducing the exchange of gases like oxygen and carbon dioxide.

End-To-End Customer Support:

Customized Film Solutions:

Solve Your Specific Pain Points

Edge warping of heat-intolerant printing materials after laminating

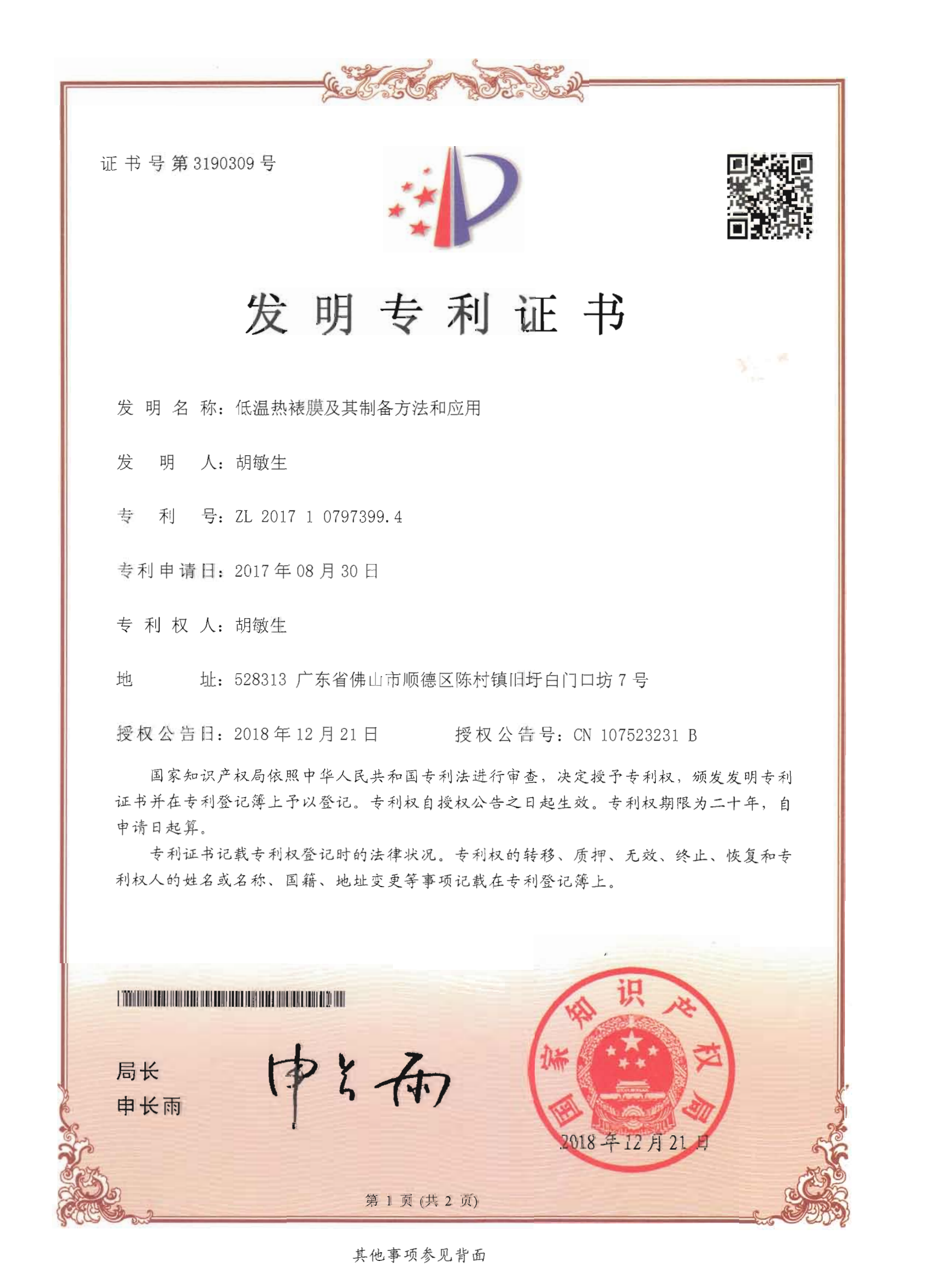

SOLUTION:LowTemperature Thermal Lamination Film

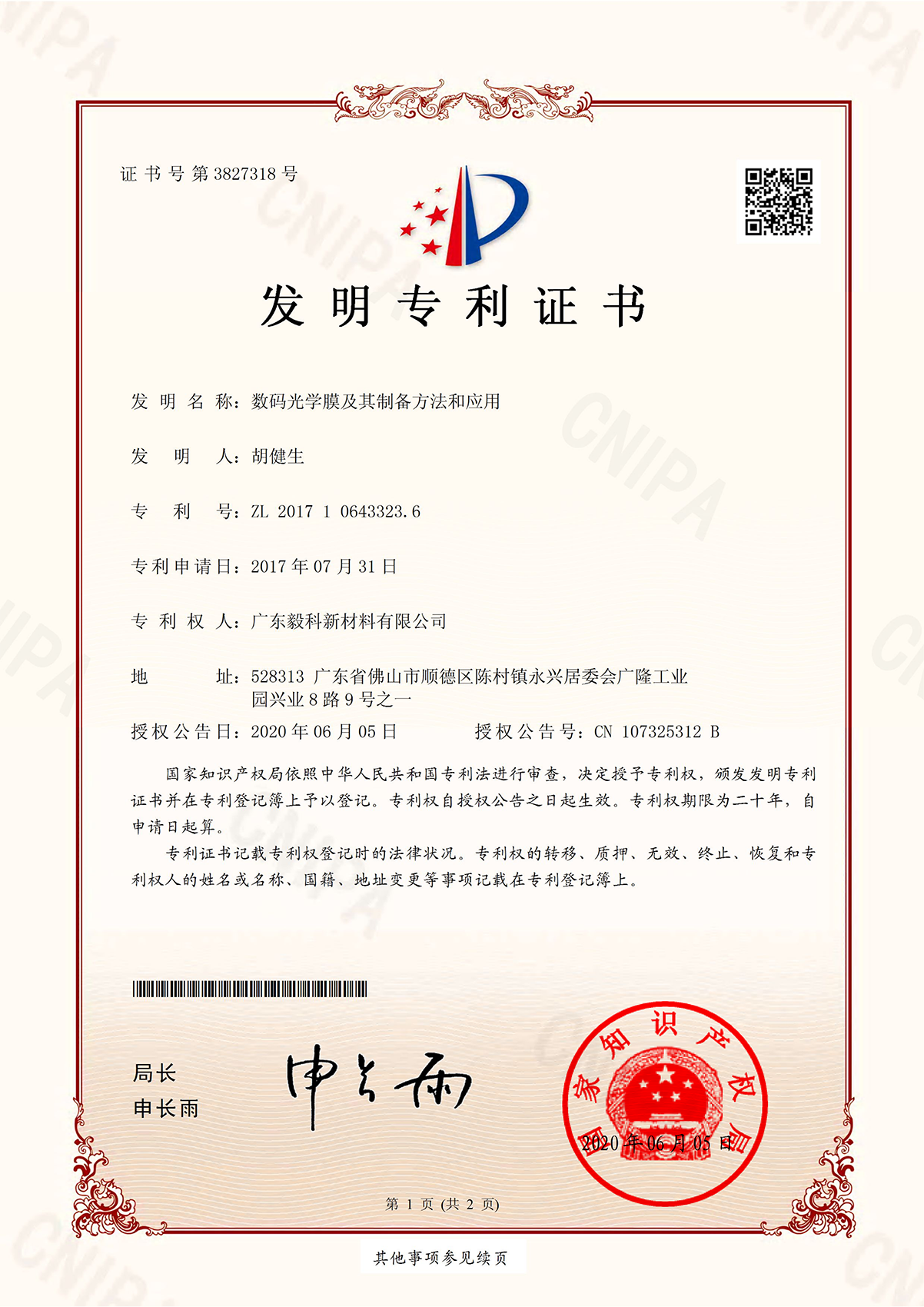

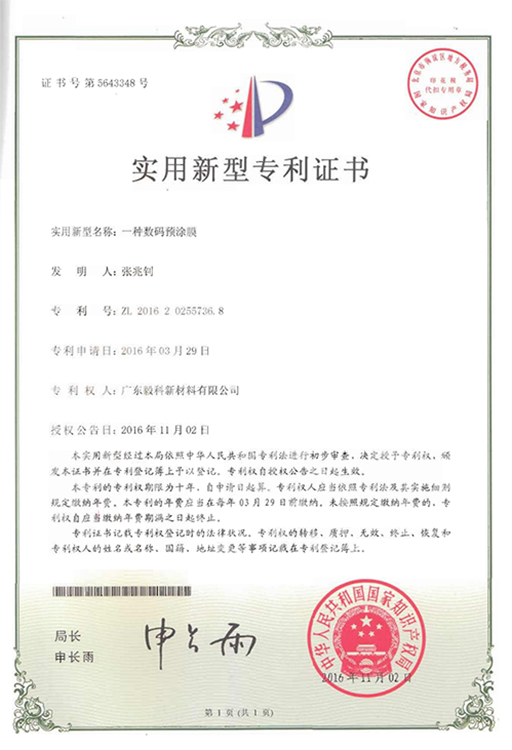

Delamination of digital toner printings after laminating

SOLUTION:Digital Thermal Lamination Film

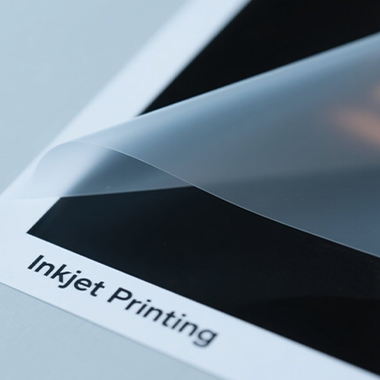

Low adhesive of inkjet printings after laminating

SOLUTION:Thermal Lamination Film for Inkjet Printing

Solution:

Deep Cooperation with School's Research Department Delivering Customized Solution

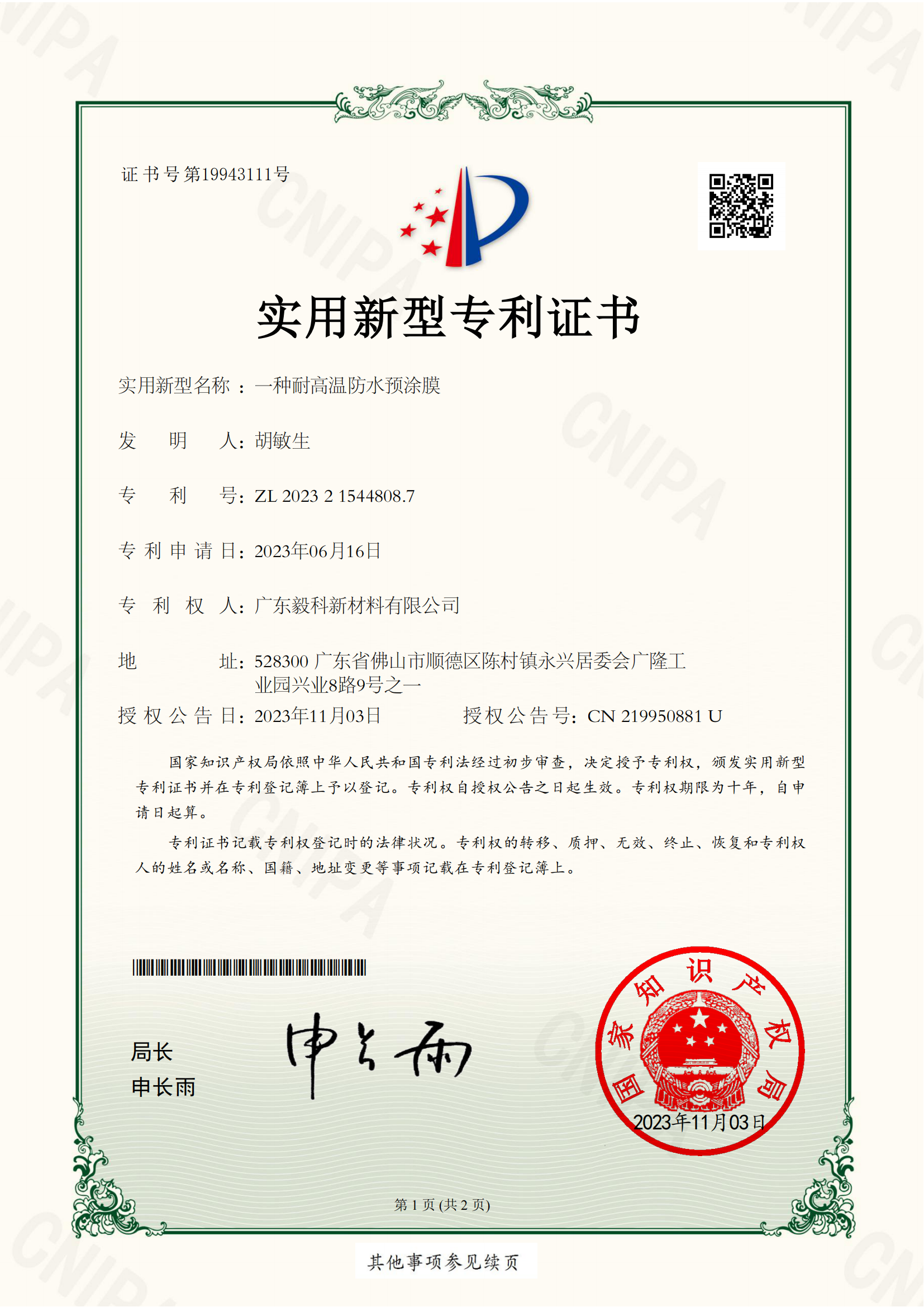

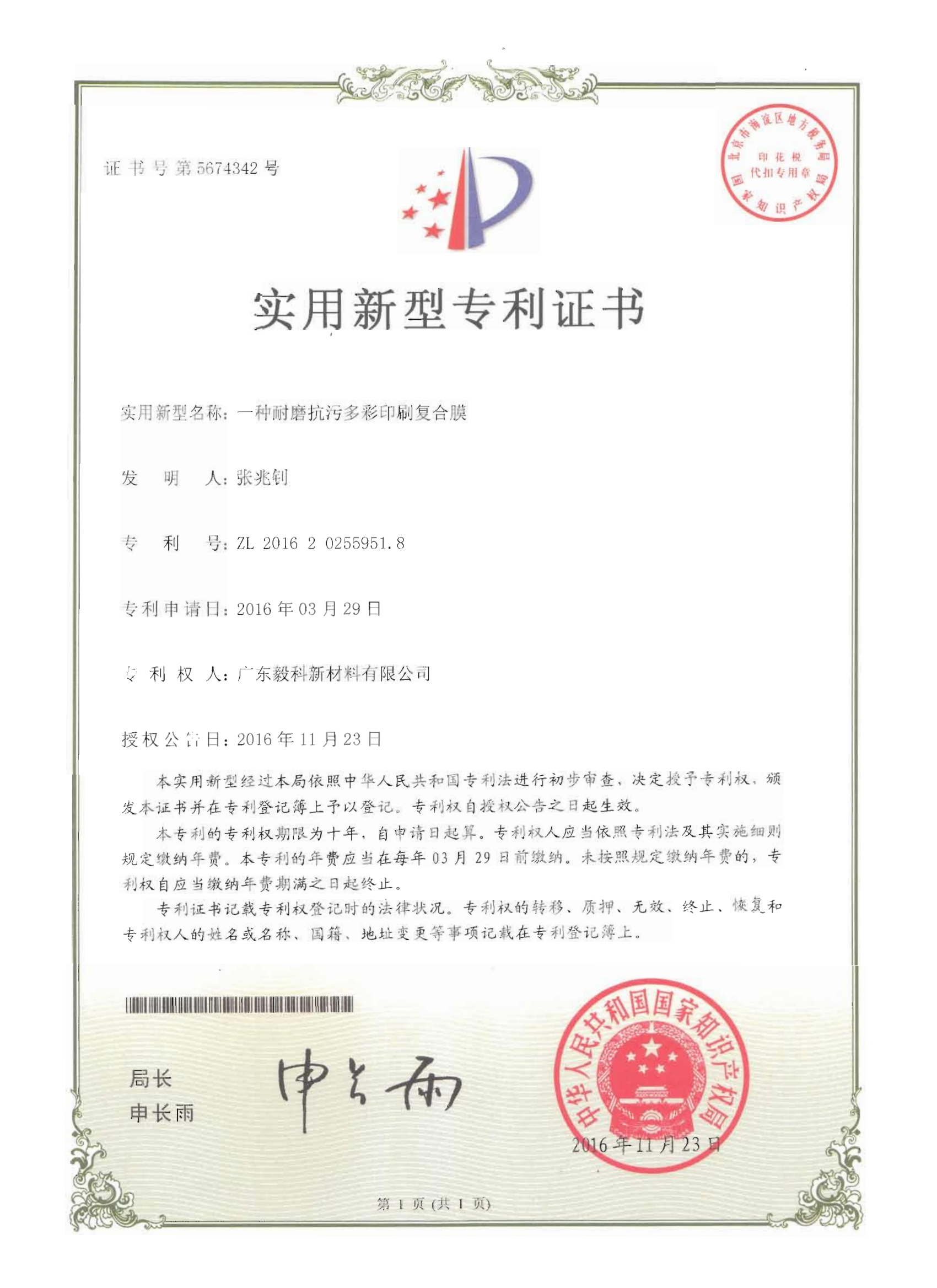

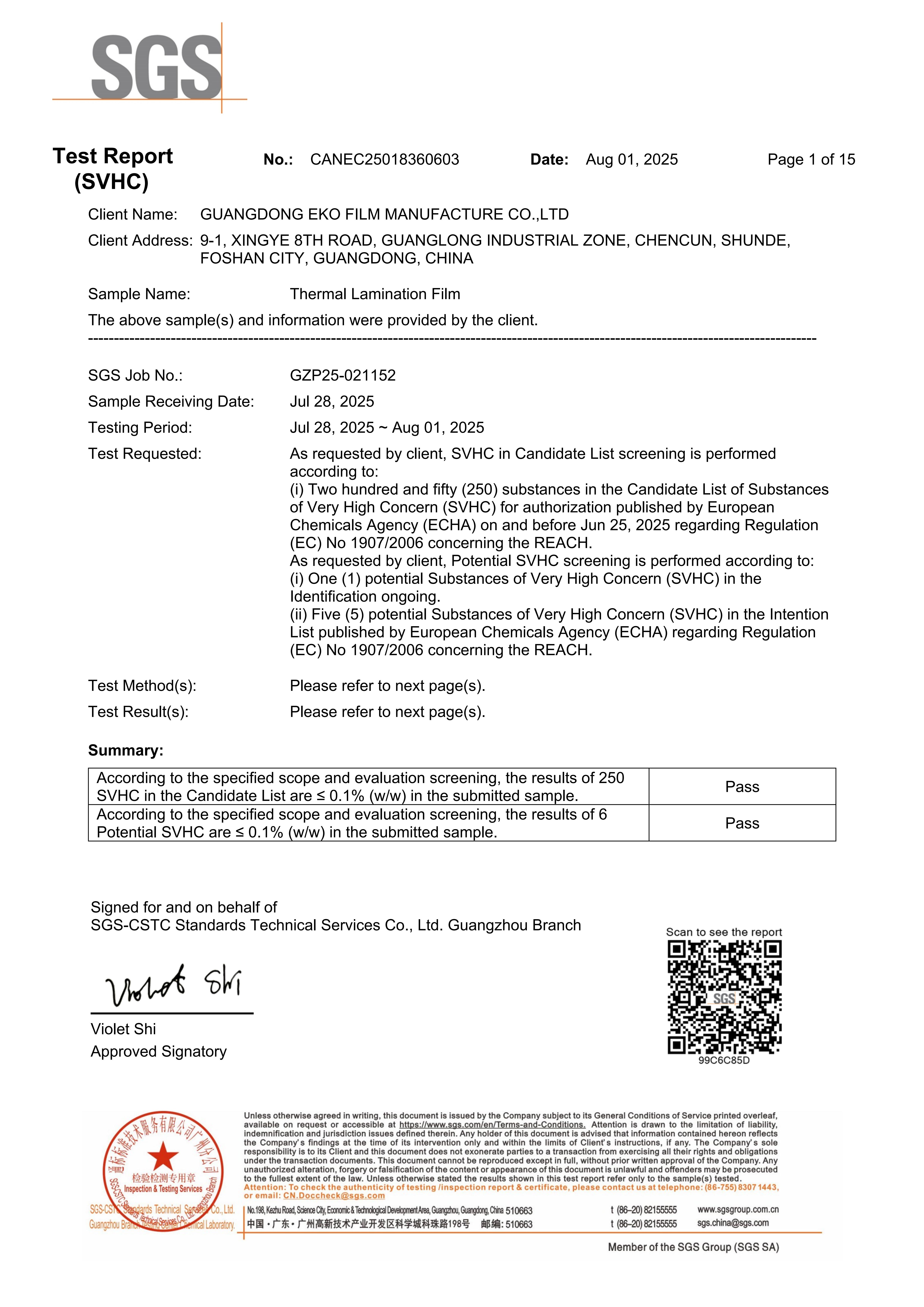

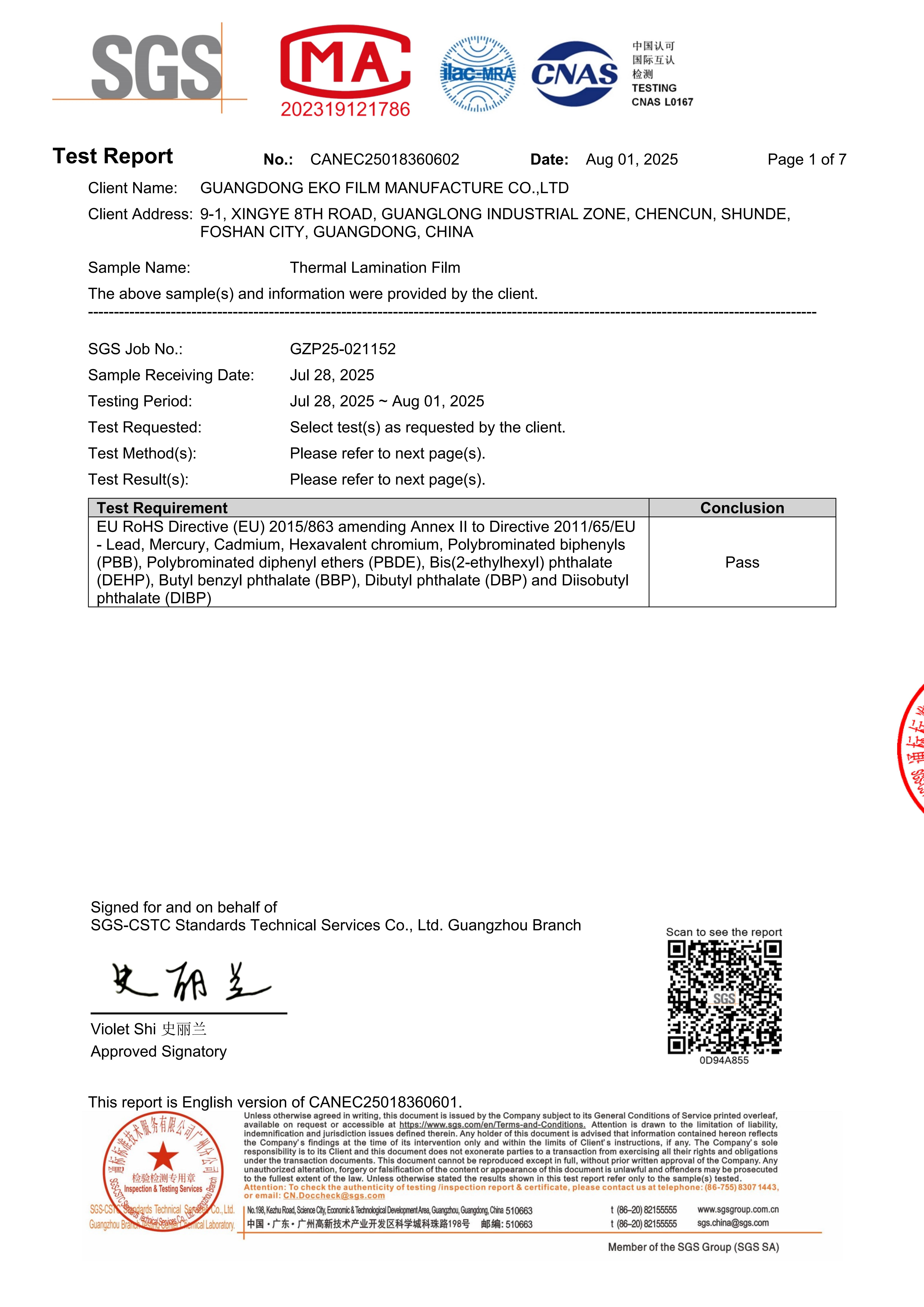

Compliance:

RoHS & REACH & Food Contact Material Triple-Certified

Packaging & Shipping:

FAQ:

Q1:Are you a factory or a trading company?

A: We are a company integrating R&D, production and sales.

Q2: How do you ensure the quality of your products?

A: We do end-to-end quality control-real time thickness check, corona value detection, bond strength testing, performance packaging.

Q3: What is your main products?

A: EKO has a broad product portfolio by catering to a wide range of industry needs, including BOPP thermal lamination film, digital super sticky thermal lamination film, thermal lamination film for inkjet printing, digital toner foil, DTF film & paper, heat sealable film, etc..

Q4: Can I get some samples or trial order for trying?

A: Yes, we provide free samples, the sample size is 320mm*30m per roll. You only need to pay for the shipping cost.

Q5: What services can we get?

A: We provide end-to-end customer support including professional customer service, customized solution, free samples, trial order, product information pack, technical consulting, full logistics tracking and feedback, comprehensive customer complaint process.

Q6: What payment terms do you offer?

A: We offer EXW, FOB, CIF, DAP, DDP, etc..