What Factors Will Effect The Quality of Thermal Lamination Film?

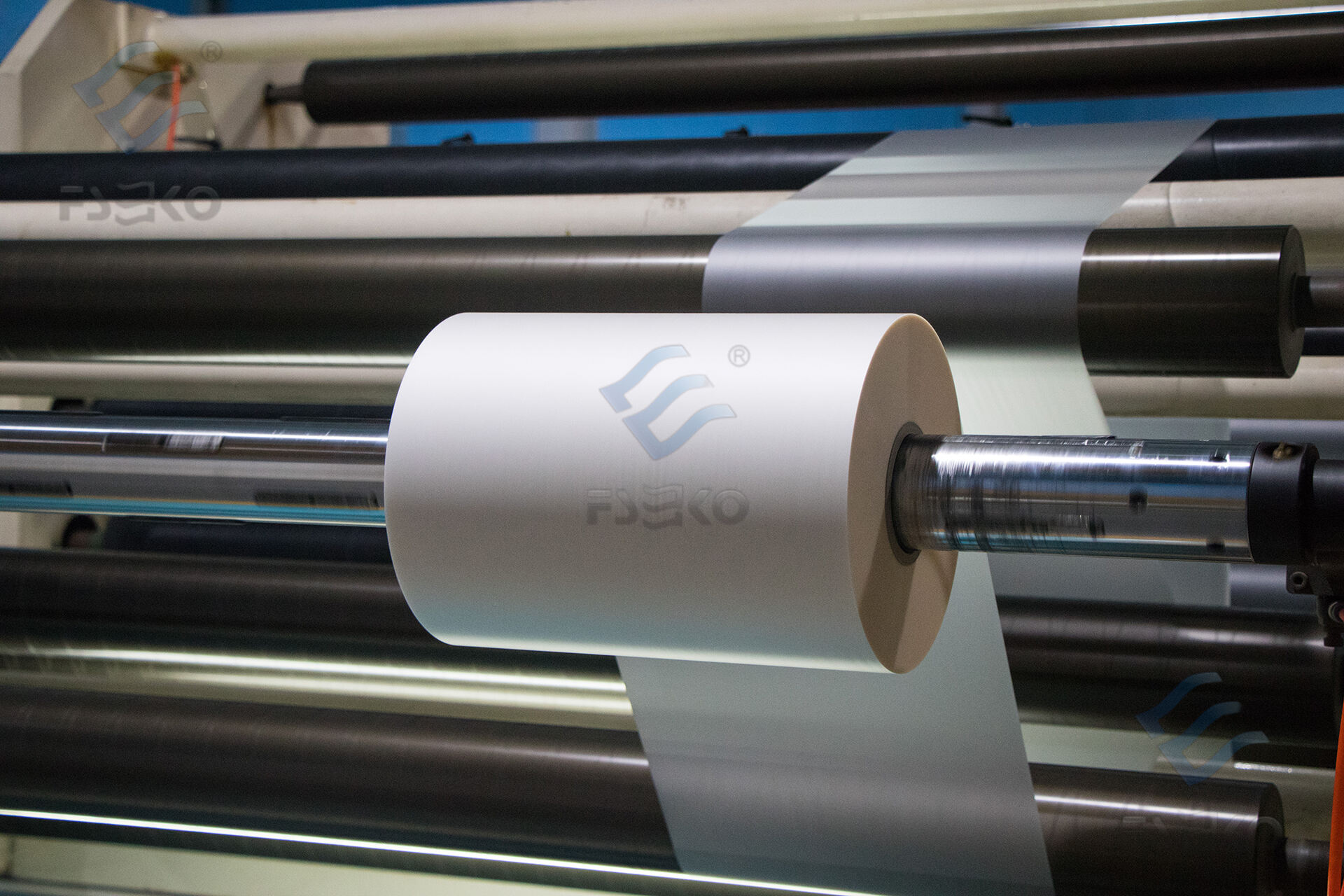

Thermal lamination film, as we know, is a composite film with EVA adhesive pre-coated onto a base film. During lamination, we simply heat the EVA using a hot press, and the film is then laminated to the printings.

What factors affect the quality of thermal lamination film during production?

Corona Value

Insufficient corona strength may result in low adhesion during lamination. Conversely, excessive corona value can lead to sedimentation in the pre-coated film. Therefore, it’s important to control the power output of the corona during production.

Typically, our corona value should be ≥38 dyne.

EVA Layer Thickness Uniformity

Uneven EVA thickness can cause bubbles and uneven surface during or after film laminating.

To avoid uneven adhesive layer thickness, EKO has introduced a thickness gauge from Germany to monitor film uniformity in real-time during coating, ensuring product quality.

High Quality Raw Materials

High quality raw materials are also a key factor in improving product quality. In terms of raw materials, EKO has always insisted on using high quality base film and premium imported EVA materials to ensure the stability of product quality and performance.