Toner folini va uning yuqori sifatli bosmachilikdagi ahamiyatini tushunish

Toner folyasi nima?

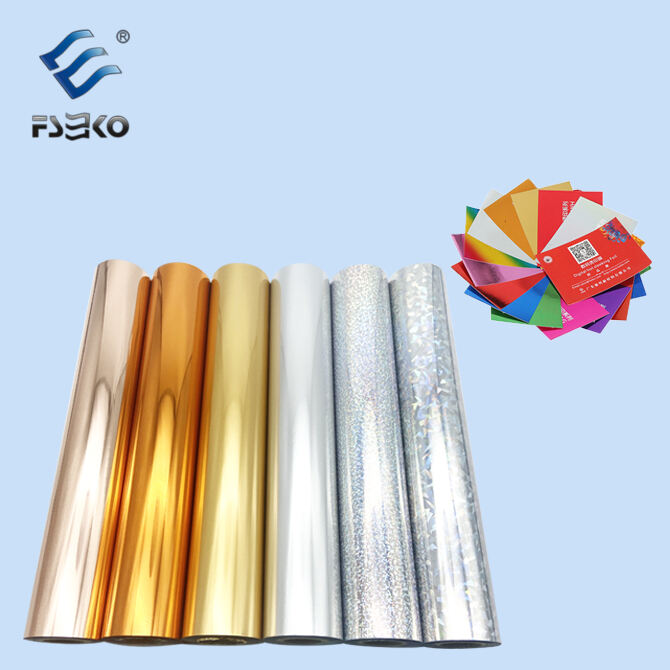

Toner folyasi issiqlik uzatish materiali bo'lib, u lazer bosma (A-) dan olingan toner bilan birlashtirilganda qog'oz, to'qimachilik va sintetik substratlarga metall yoki holografik yoki mat finişlar yaratadi. Ular raqamli birinchi jarayon yaratdi, unda toner yopishqoq asos bo'lib, shuning uchun an'anaviy issiq bosish kabi maxsus o'simliklar kerak emas. Issiq va bosim ostida bo'lganda (300-350 ° F yoki shu qadar), foliya faqat bosilgan joylarga tanlab yopiladi, natijada qo'shimcha plita ishlab chiqarish xarajatlari talab qilinmasdan aniq logotiplar va murakkab naqshlar paydo bo'ladi.

Toner foliyasi raqamli foliyani bosib chiqarish usullarini qanday qoʻllaydi

Raqamli foliya bosimi lazerli aniqlikni ta'sirli hashamat bilan birlashtiradi:

- Lazerli printer tonerni kerakli shakldagi foliyaga joylashtiradi.

- Foliya varaqlari bosilgan substrat ustiga qatlamlar bilan qoplanadi.

- Issiqlik bosish vositasi bilan bir xil issiqlik va bosim qo'llanib, tonerni folyada eritadi.

Ushbu jarayon analog folyolash bilan taqqoslaganda o'rnatish vaqtini 60% ga qisqartiradi, ammo 1200 dpi aniqlikni saqlab qoladi, bu uni to'y taklifiga yoki hashamatli qadoqlashlarga ideal qiladi.

Lazerli printerlar va raqamli bosma mashinalar bilan moslashuvchanligi

Foliyani bosib chiqarish uchun printerga qo'yiladigan asosiy talablar:

| Printerning xususiyati | Talab |

|---|---|

| Fusyer harorati | Oʻzgartiriladigan (300 - 375 ° F) |

| OAVning ogʻirligi | 80 - 130 funtlik matn vazni |

| Toner turi | Polimerlashtirilgan (mash asosli bo'lmagan) |

Xerox Versant va HP Indigo kabi yuqori darajadagi qurilmalar foliya ish jarayonlarida ustunlik qiladi. Katta miqyosdagi loyihalar uchun, chiziqli foliyantsiya modullari bilan jihozlangan raqamli presslar soatiga 5000+ varaq ishlab chiqarishi mumkin.

Toner folini oʻtkazishning ilmiy yoʻnalishi: Issiqlik, bosim va yopish

Foliya uchun yopishqoq qatlam sifatida tonerni eritish

300-325°F gacha issiq bo'lganda, tonerning termoplastik polimerlari erib, intermolekulyar tortish orqali foyaning yopishqoq tayanchi bilan bog'lanadigan texturli sirt hosil qiladi. An'anaviy bosmalardan farqli o'laroq, raqamli usullar tonerning elektrostatik xususiyatlaridan aniq yopish uchun foydalanadi, bu esa jismoniy o'simliklarsiz murakkab naqshlarni yaratishga imkon beradi.

Foliyalarni qo'llashda issiqlik va bosim dinamikasi

Optimal uzatish quyidagilarni talab qiladi:

- Harorat polimerlarni bug'lantirib yubormasdan tonerni yumshatish uchun: 300-325°F.

- Bosim : 40 - 60 psi substratlar o'rtasida bir xil kontakt uchun.

- Muddatli to'xtash : 10 - 15 soniya adhessiya bog'lamalarini qattiqlashtirish uchun.

± 10 ° F yoki 5 PSI dan ortiq chetlanish adheziyani 60% gacha kamaytirishi mumkin.

Nega raqamli foliyalarni uzatishda aniqlik muhim ahamiyatga ega?

Kalibratsiya halo effektlari yoki foliya qon ketish kabi nuqsonlarni oldini oladi. Zamonaviy raqamli presslar ± 2 ° F aniqlikni saqlab qolishadi, bu hashamatli qadoqlash xavfsizligi xususiyatlarida 0,1 mm tafsilot uchun juda muhimdir.

Professional natijalar uchun toner folini qo'llash bo'yicha qadamma- qadam ko'rsatma

Toner folyasi ta'siri bilan maksimal ta'sirni ta'minlash uchun dizayn qilish

Foliya uchun jasur chiziqlar (qalinligi ≤ 2pt) va geometrik naqshlar bilan dizaynlarni optimallashtirish, bu esa yopishishni 43% ga oshiradi. Chiziqli chekkalish uchun vektorli dasturlardan foydalaning.

| Loyiha elementi | Eng yaxshi xususiyatlar |

|---|---|

| Chiziq qalinligi | 2-5 t |

| Matn hajmi | ‰¥12pt |

| Toner zichligi | 0,8-1,0 g/m2 |

Toner bazasini bosib chiqarish: maqbul sozlamalar va ommaviy axborot vositalarini tanlash

Bosish moslamalarini sozlash:

- Fyuzer harorati: 260 - 285 ° F

- Toner zichligi: 60 - 80% qoplash

- OAVning og'irligi: 80 - 130 lb matn / muqova

Qoplamali qog'ozlardan qoching - ular tonerning mahkamlanishini 70% gacha kamaytiradi.

Issiqlik bosish yoki laminator yordamida foliyalarni uzatish

Issiq bilan bosish 300-315 ° F, 45-55 psi, 25-35 soniya.

Laminator : 285 - 295 ° F, 0,8 - 1,2 IPS.

Yirnoqlarni 62% kamaytirish uchun 90° burchakda qo'yish kerak.

Toza va hashamatli pardozlash uchun peeling texnikasi

- Тезиқлаштириш substrat 70 ° F gacha bo'lmaguncha 15 - 30 soniya kuting.

- Burchak metall foljalar uchun 45 - 60° saqlang.

- Tezlik : qisman oʻtishining oldini olish uchun 2 - 3 dyuym/s tezlikda olib tashlang.

Toner folini yuksak sifatli bosma loyihalarida ijodiy qoʻllash

Foliyadan yasalgan karton va qadoqlashlarni yuqori koʻrinishga keltirish

Toner foliyasi vizitkalar va qadoqlashlarda ko'rinadigan qiymatni 60% ga oshiradi. Asosiy foydalanish turlari quyidagilardan iborat:

- Muhrli stikerlar : Ko'zgu mahsulotlari uchun ologrammaviy foliyalar.

- Qattiq qutilar : Rebozlangan logotiplarda spotfoliya.

- Qo'lqoplar : To'liq qoplamali metalllar cheklangan nashrlar uchun.

Foliyali qadoqlash 48 foiz tezroq raflarni tan olishga erishadi.

Oʻlchovli foliyali detallar bilan sanʼat bosmalari va taklifnomalar

Metallikalarning ton-on-ton yoki matritsiya bilan kesilgan foliya kabi texnikasi laminatlangan plyonkalarga nisbatan chiqindilarni 34% ga kamaytiradi. Interaktiv foliya elementlari (masalan, xarid qilish uchun RSVP) mijozlarning mamnuniyatini 40% ga oshiradi.

Foliyani toʻliq koʻchirishning sabablari va yechimlari

Koʻpchilik buzilishlar 275°F yoki < 15 soniya turish vaqtidan past boʻlgan holatlarda sodir boʻladi. Barqarorlik uchun:

| Фабрика | Issiqlik bosmachi oʻrnatish | Laminatorni sozlash |

|---|---|---|

| Harorat | 290 - 310 ° F | 300 - 320 ° F |

| Bosim | O'rtacha og'ir | 4 - 5 bar |

| Muddatli to'xtash | 18 - 22 soniya | 20 - 25 soniya |

Foliyalarning ortiqcha yopishishi va chiqindilarning oldini olish

Quyidagilar orqali samaradorlikni optimallashtirish:

- Foliyani bosilgan joylardan tashqariga 0,5 dyuymgacha kesib tashlash.

- Loyihalashtirilmagan zonalarda silikon bilan qoplangan pergamentdan foydalanish.

- Ikki bosqichli harorat rampalarini (285 ° F - 305 ° F) amalga oshirish.

Toner folyasi va raqamli folya bosishidagi yangilik

Ilgʻor natijalarga quyidagilar kiradi:

- Past haroratdagi foljalar : 250 ° F haroratida bogʻlanish.

- Aqlli tashuvchi varaqlar : Avto-konfiguratsiya qilish bosing.

- Mikro-perforatlangan foljalar : ko'p qatlamli effektlar uchun 0,2 mm aniqlik.

2026 yilga kelib raqamli foliya bozori 39 foizga yetishi kutilmoqda.

Ko'p so'raladigan savollar

Toner foliyasini uzatish uchun qanday haroratlar ideal?

Toner foliyasini uzatish uchun ideal harorat oralig'i 300-325 ° F oralig'ida bo'lib, tonerning foliyani bog'lash uchun etarlicha erishi mumkin.

Nima uchun toner foliyasi qisqa muddatli matbaa uchun afzal koʻriladi?

Toner folyasi qisqa muddatli hashamatli bosma uchun afzal ko'riladi, chunki u yuqori aniqlikdagi (1200 dpi) dizaynlarni ishlab chiqarish, o'rnatish vaqtini 60% ga qisqartirish va maxsus matnlarga bo'lgan ehtiyojni bartaraf etish qobiliyatiga ega.

Toner foliyasi qanday ijodiy qo'llanilmoqda?

Toner folyasi biznes kartalari, qadoqlash, san'at bosmalari va taklifnomalar kabi hashamatli bosma loyihalarda ijodiy ravishda ishlatilishi mumkin, bu esa mahsulotlarni folya aksentlari va interaktiv elementlari bilan yaxshilaydi.

Mundarija

- Toner folini va uning yuqori sifatli bosmachilikdagi ahamiyatini tushunish

- Toner folini oʻtkazishning ilmiy yoʻnalishi: Issiqlik, bosim va yopish

- Professional natijalar uchun toner folini qo'llash bo'yicha qadamma- qadam ko'rsatma

- Toner folini yuksak sifatli bosma loyihalarida ijodiy qoʻllash

- Foliyani toʻliq koʻchirishning sabablari va yechimlari

- Foliyalarning ortiqcha yopishishi va chiqindilarning oldini olish

- Toner folyasi va raqamli folya bosishidagi yangilik

- Ko'p so'raladigan savollar