টোনার ফয়েল এবং এর গুরুত্ব সম্পর্কে জানুন

টোনার ফয়েল কি?

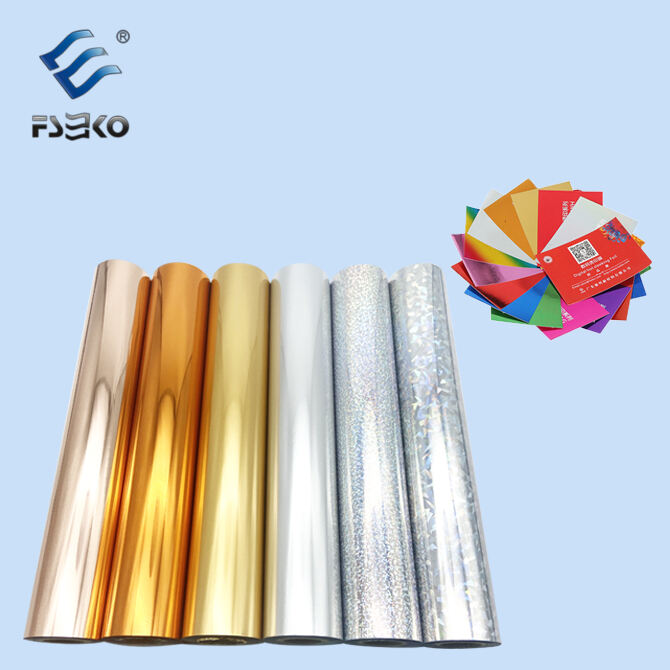

টোনার ফয়েল একটি তাপ স্থানান্তর উপাদান, যা লেজার প্রিন্টিং (এ-) থেকে টোনারের সাথে মিলিত হলে কাগজ, টেক্সটাইল এবং সিন্থেটিক সাবস্ট্র্যাটে ধাতব বা হলোগ্রাফিক, বা ম্যাট সমাপ্তি তৈরি করে। তারা একটি ডিজিটাল-প্রথম প্রক্রিয়া তৈরি করেছে যেখানে টোনার হল আঠালো বেস, তাই কোনো কাস্টম মেইলের প্রয়োজন নেই, ঠিক যেমন ঐতিহ্যগত হট স্ট্যাম্পিং। যখন তাপমাত্রা এবং চাপের অধীনে (300-350 ডিগ্রি ফারেনহাইট বা তার বেশি) থাকে, তখন ফয়েলটি কেবলমাত্র মুদ্রিত অঞ্চলে নির্বাচনীভাবে সংযুক্ত হয়, যার ফলে অতিরিক্ত প্লেট তৈরির খরচ ছাড়াই স্পষ্ট লোগো এবং জটিল নিদর্শন পাওয়া যায়।

টোনার ফয়েল কিভাবে ডিজিটাল ফয়েল প্রিন্টিং কৌশল সক্ষম করে

ডিজিটাল ফয়েল প্রিন্টিং লেজার নির্ভুলতাকে স্পর্শকাতর বিলাসিতা দিয়ে মিশ্রিত করে:

- লেজার প্রিন্টার টোনারকে পছন্দসই ফোলির মোডে জমা করে।

- ফয়েল শীটগুলি মুদ্রিত স্তরটির উপরে স্তরিত হয়।

- একটি তাপ প্রেস ত্বকের উপর সমান তাপ এবং চাপ প্রয়োগ করে, ফয়েলটিতে টোনার মিশ্রিত করে।

এই প্রক্রিয়াটি 1200 ডিপিআই রেজোলিউশন বজায় রেখে আনাগলিক ফয়েলিংয়ের তুলনায় 60% সেটআপ সময় হ্রাস করে, এটি বিবাহের আমন্ত্রণ বা বিলাসবহুল প্যাকেজিংয়ের স্বল্প রানগুলির জন্য আদর্শ করে তোলে।

লেজার প্রিন্টার এবং ডিজিটাল প্রেসের সাথে সামঞ্জস্য

ফোলিংয়ের জন্য প্রিন্টারের মূল প্রয়োজনীয়তাঃ

| প্রিন্টারের বৈশিষ্ট্য | প্রয়োজনীয়তা |

|---|---|

| ফিউজার তাপমাত্রা | নিয়মিত (300- 375°F) |

| মিডিয়া ওজন | ৮০-১৩০ পাউন্ডের পাঠ্য ওজন |

| টোনার টাইপ | পলিমারাইজড (মোম ভিত্তিক নয়) |

এক্সেরক্স ভার্সান্ট এবং এইচপি ইন্ডিগো এর মত হাই-এন্ড ডিভাইসগুলি ফয়েল ওয়ার্কফ্লোতে চমৎকার। বড় আকারের প্রকল্পের জন্য, ইনলাইন ফোলিং মডিউল সহ ডিজিটাল প্রেসগুলি 5,000+ শীট / ঘন্টা আউটপুট করতে পারে।

টোনার ফয়েল স্থানান্তরের পেছনের বিজ্ঞান: তাপ, চাপ, এবং আঠালো

ফয়েল জন্য আঠালো স্তর হিসাবে ফিউজিং টোনার

যখন ৩০০-৩২৫ ডিগ্রি ফারেনহাইট পর্যন্ত গরম করা হয়, তখন টোনার থার্মোপ্লাস্টিক পলিমার গলে যায়, একটি টেক্সচারযুক্ত পৃষ্ঠ তৈরি করে যা আন্তঃমোলেকুলার আকর্ষণের মাধ্যমে ফয়েলটির আঠালো ব্যাকপ্যাকের সাথে আবদ্ধ হয়। ঐতিহ্যগত স্ট্যাম্পিংয়ের বিপরীতে, ডিজিটাল পদ্ধতিগুলি টোনার ইলেক্ট্রোস্ট্যাটিক বৈশিষ্ট্যগুলিকে সুনির্দিষ্ট সংযুক্তির জন্য ব্যবহার করে, যা শারীরিক মুর্তি ছাড়াই জটিল নিদর্শনগুলি সক্ষম করে।

ফয়েল অ্যাপ্লিকেশনে তাপ ও চাপের গতিবিদ্যা

সর্বোত্তম স্থানান্তর প্রয়োজনঃ

- তাপমাত্রা : 300-€ 325°F পলিমার বাষ্পীভূত না করে টোনার নরম করতে।

- চাপ : 40-60 PSI সবস্ট্র্যাট জুড়ে অভিন্ন যোগাযোগের জন্য।

- থাকার সময় : ১০-১৫ সেকেন্ডের মধ্যে আঠালো বন্ধন শক্ত হয়ে যাবে।

±10°F বা 5 PSI এর বেশি বিচ্যুতি 60% পর্যন্ত সংযুক্তি হ্রাস করতে পারে।

ডিজিটাল ফয়েল ট্রান্সফারে কেন নির্ভুলতা গুরুত্বপূর্ণ

ক্যালিব্রেশন হ্যালো ইফেক্ট বা ফয়েল রক্তপাতের মত ত্রুটি প্রতিরোধ করে। আধুনিক ডিজিটাল প্রেসগুলি ± 2 ° F নির্ভুলতা বজায় রাখে, যা বিলাসবহুল প্যাকেজিং সুরক্ষা বৈশিষ্ট্যগুলিতে 0.1 মিমি বিশদগুলির জন্য গুরুত্বপূর্ণ।

পেশাদার ফলাফলের জন্য টোনার ফয়েল প্রয়োগের ধাপে ধাপে গাইড

টোনার ফয়েল ইফেক্টের মাধ্যমে সর্বোচ্চ প্রভাবের জন্য ডিজাইন করা

সাহসী লাইন (≥2pt বেধ) এবং জ্যামিতিক নিদর্শন সহ ফয়েলগুলির জন্য ডিজাইনগুলি অনুকূল করুন যা 43% দ্বারা সংযুক্তি উন্নত করে। স্পষ্ট প্রান্তের জন্য ভেক্টর ভিত্তিক সফটওয়্যার ব্যবহার করুন।

| ডিজাইন উপাদান | সর্বোত্তম স্পেসিফিকেশন |

|---|---|

| লাইন বেধ | ২-৫ পিটি |

| টেক্সটের আকার | ¥¥12pt |

| টোনার ঘনত্ব | 0.8-1.0g/mÂ2 |

টোনার বেস মুদ্রণ করাঃ সর্বোত্তম সেটিংস এবং মিডিয়া নির্বাচন

নিম্নলিখিতগুলির জন্য প্রেস কনফিগার করুনঃ

- ফিউজার তাপমাত্রাঃ 260-€ 285°F

- টোনার ঘনত্বঃ 60-80% কভারেজ

- মিডিয়া ওজনঃ 80-€130 পাউন্ড পাঠ্য / কভার স্টক

লেপযুক্ত কাগজ এড়িয়ে চলুন-এগুলি টোনার অ্যাঙ্করিংকে 70% পর্যন্ত হ্রাস করে।

তাপ প্রেস বা ল্যামিনেটর ব্যবহার করে ফয়েল স্থানান্তর

হিট প্রেস ৩০০-৩১৫ ফারেনহাইট, ৪৫-৫৫ সাই, ২৫-৩৫ সেকেন্ড।

ল্যামিনেটর : ২৮৫-২৯৫ ফারেনহাইট, ০.৮-১.২ আইপিএস।

৯০ ডিগ্রি কোণে পিল করুন, ফলে ভাঙ্গন ৬২% কমে যাবে।

পরিষ্কার, বিলাসবহুল সমাপ্তির জন্য পিলিং কৌশল

- শীতল : ১৫-৩০ সেকেন্ড অপেক্ষা করুন যতক্ষণ না সাবস্ট্র্যাট ৭০ ডিগ্রি ফারেনহাইটের উপরে পৌঁছে যায়।

- কোণ : ধাতব ফোল্ডার জন্য 45-60° বজায় রাখুন।

- গতি : আংশিক স্থানান্তর রোধ করতে 2 - 3 ইঞ্চি / সেকেন্ড এ সরান।

বিলাসবহুল মুদ্রণ প্রকল্পে টোনার ফোলির সৃজনশীল অ্যাপ্লিকেশন

ফয়েল অ্যাকসেন্ট দিয়ে ভিজিট কার্ড এবং প্যাকেজিংয়ের উচ্চতা

টোনার ফয়েল ভিজিট কার্ড এবং প্যাকেজিংয়ের ক্ষেত্রে ৬০% মূল্য বৃদ্ধি করে। এর প্রধান ব্যবহারের মধ্যে রয়েছেঃ

- সীল স্টিকার : প্রসাধনী জন্য হলোগ্রাফিক ফয়েল।

- ঠক্কা বক্স : প্রতীকিত লোগোগুলিতে স্পট ফয়েল।

- স্লিভ : সীমিত সংস্করণের জন্য পূর্ণ কভারেজ ধাতব।

ফয়েল প্যাকেজিং 48% দ্রুত তাক স্বীকৃতি অর্জন করে।

আকারের ফয়েল বিশদ সহ আর্ট প্রিন্ট এবং আমন্ত্রণ

টোন-অন-টোন ধাতব বা ডাই-কাট ফয়েল মত কৌশলগুলি ল্যামিনেটেড শীটগুলির তুলনায় 34% দ্বারা বর্জ্য হ্রাস করে। ইন্টারেক্টিভ ফয়েল উপাদান (যেমন, স্ক্র্যাচ-অফ RSVP) গ্রাহকের সন্তুষ্টি 40% বৃদ্ধি করে।

অসম্পূর্ণ ফয়েল স্থানান্তরঃ কারণ এবং সমাধান

বেশিরভাগ ব্যর্থতা ২৭৫° ফারেনহাইট বা <১৫ সেকেন্ডের নিচে ঘটে। ধারাবাহিকতার জন্যঃ

| গুণনীয়ক | তাপ প্রেস সেটিং | ল্যামিনেটর সেটিং |

|---|---|---|

| তাপমাত্রা | ২৯০-৩১০° ফারেনহাইট | ৩০০-৩২০° ফারেনহাইট |

| চাপ | মাঝারি ভারী | ৪-৫ বার |

| থাকার সময় | ১৮-২২ সেকেন্ড | ২০-২৫ সেকেন্ড |

অতিরিক্ত ফয়েল আঠালো এবং বর্জ্য প্রতিরোধ

নিম্নলিখিত পদ্ধতির মাধ্যমে দক্ষতা বাড়ানোঃ

- মুদ্রিত এলাকার বাইরে 0.5 " পর্যন্ত ফয়েল ট্রিমিং।

- নকশাবিহীন এলাকায় সিলিকন লেপযুক্ত পেগামেন্ট ব্যবহার করা।

- দ্বি-পর্যায়ের তাপমাত্রা র্যাম্প (285°F - 305°F) বাস্তবায়ন।

টোনার ফয়েল এবং ডিজিটাল ফয়েল প্রিন্টিংয়ের ক্ষেত্রে উদ্ভাবনী উদ্ভাবন

অগ্রগতিগুলির মধ্যে রয়েছেঃ

- নিম্ন তাপমাত্রার ফয়েল : বন্ড 250°F এ।

- স্মার্ট ক্যারিয়ার শীট : স্বয়ংক্রিয়ভাবে কনফিগার প্রেস সেটিংস.

- মাইক্রো-পোরফারেটেড ফয়েল : মাল্টি-লেয়ার ইফেক্টের জন্য 0.2 মিমি নির্ভুলতা।

২০২৬ সালের মধ্যে ডিজিটাল ফয়েল বাজারে ৩৯ শতাংশ ব্যবহারের সম্ভাবনা রয়েছে।

FAQ

টোনার ফয়েল স্থানান্তরের জন্য কোন তাপমাত্রা আদর্শ?

টোনার ফয়েল স্থানান্তরের জন্য আদর্শ তাপমাত্রা পরিসীমা 300-325 ডিগ্রি ফারেনহাইটের মধ্যে, যা টোনারকে ফয়েলটির সাথে বন্ধন করার জন্য পর্যাপ্ত পরিমাণে গলে যাওয়ার অনুমতি দেয়।

কেন টোনার ফয়েলকে স্বল্পমেয়াদী বিলাসবহুল মুদ্রণের জন্য পছন্দ করা হয়?

উচ্চ রেজোলিউশনের (1,200 ডিপিআই) ডিজাইন তৈরি করার ক্ষমতা, সেটআপের সময় 60% হ্রাস এবং কাস্টম মেইডের প্রয়োজন দূর করার কারণে টোনার ফয়েল স্বল্প-কালীন বিলাসবহুল মুদ্রণের জন্য পছন্দ করা হয়।

টোনার ফোলির কিছু সৃজনশীল ব্যবহার কি?

টোনার ফয়েলটি বিলাসবহুল মুদ্রণ প্রকল্প যেমন ভিজিট কার্ড, প্যাকেজিং, আর্ট প্রিন্ট এবং আমন্ত্রণের মতো সৃজনশীলভাবে ব্যবহার করা যেতে পারে, ফয়েল অ্যাকসেন্ট এবং ইন্টারেক্টিভ উপাদানগুলির সাথে পণ্যগুলিকে উন্নত করে।

সূচিপত্র

- টোনার ফয়েল এবং এর গুরুত্ব সম্পর্কে জানুন

- টোনার ফয়েল স্থানান্তরের পেছনের বিজ্ঞান: তাপ, চাপ, এবং আঠালো

- পেশাদার ফলাফলের জন্য টোনার ফয়েল প্রয়োগের ধাপে ধাপে গাইড

- বিলাসবহুল মুদ্রণ প্রকল্পে টোনার ফোলির সৃজনশীল অ্যাপ্লিকেশন

- অসম্পূর্ণ ফয়েল স্থানান্তরঃ কারণ এবং সমাধান

- অতিরিক্ত ফয়েল আঠালো এবং বর্জ্য প্রতিরোধ

- টোনার ফয়েল এবং ডিজিটাল ফয়েল প্রিন্টিংয়ের ক্ষেত্রে উদ্ভাবনী উদ্ভাবন

- FAQ