Thermal Lamination Film FAQ

Q1: What is thermal lamination film?

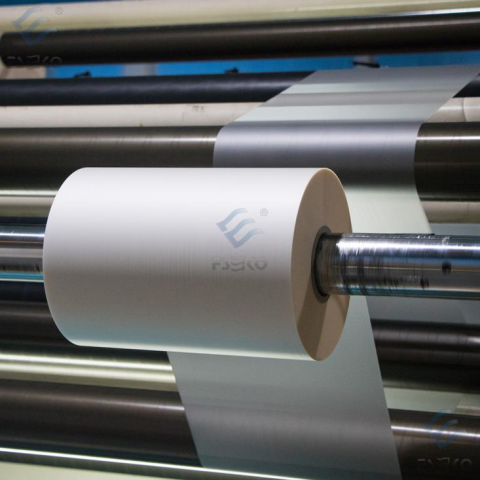

A: Thermal lamination film, as known as pre-coated film, is commonly used in packaging and printing industry to protect and enhance the surface of the printings. It’s a multiple layer composite film, usually composed of a base film and a hot melt adhesive layer(what EKO uses is EVA). This film should be used with thermal laminator. When the film is subjected to a certain temperature and pressure, it will firmly adhere to the surface of the printings to form a solid protective.

Q2: What the advantages of thermal lamination film?

A: 1. Protection: Thermal lamination film provides a protective layer against moisture, UV rays, scratches, and other physical damage. It helps extend the lifespan and integrity of printed materials, making them more durable.

2.Enhanced Visual Effects: Thermal lamination materials can impart a glossy or matte finish to printings, enhancing their appearance and adding a professional feel. They also improve the color saturation and contrast of printed designs, making them more visually appealing.

3.Easy Cleaning: The thermal lamination film's smooth surface makes it easy to clean. Any fingerprints or dirt can be easily wiped off without damaging the printed material underneath.

4.Versatility: Thermal lamination film can be used for a variety of printings, such as book covers, posters, packaging, labels, and promotional materials. It is compatible with various printing techniques and can be applied to both paper and synthetic substrates.

Q3: How to use thermal lamination film?

A: Using thermal lamination film is a relatively process. Here are the general steps.

1.Prepare the printed materials: Ensure the printed materials is clean and free of dust or debris.

2.Set up the laminator: Follow the instructions included with the laminator to set up the laminator correctly. Adjust the temperature and speed settings according to the type of hot laminating material being used.

3.Position the film: Place one or more rolls of hot laminating materials on the laminator, ensuring they are aligned.

4.Load the printed material: Insert the printed material into the laminator, ensuring it is aligned with the film.

5.Start the laminating process: Start the machine to begin the laminating process. The heat and pressure generated by the machine activate the adhesive layer, bonding the film to the printed material. Ensure that the laminating film exits the other end of the machine smoothly.

6.Trimming excess film: After lamination is complete, use a cutting tool or trimmer to trim any excess film from the edges of the laminating material, if necessary.

Q4: How many types of thermal lamination film does EKO have?

A: In order to meet different needs, EKO have diverse film:

BOPP thermal lamination film

PET thermal lamination film

Soft touch thermal lamination film

Anti-scratch thermal lamination film

Digital thermal lamination film

Thermal lamination film for inkjet printing

Metalized thermal lamination film

Digital toner foil

DTF film

DTF paper

etc.