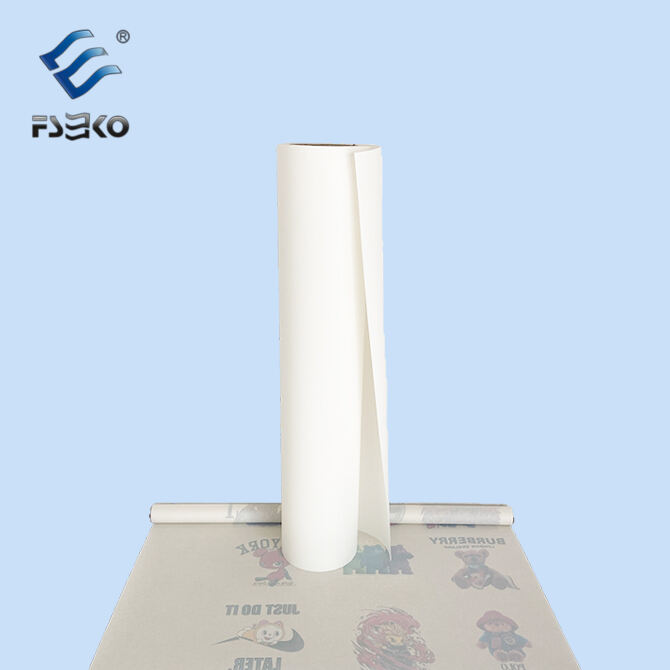

DTF Transfer Film

- Product name: DTF transfer paper

- Gram weight:70g/㎡

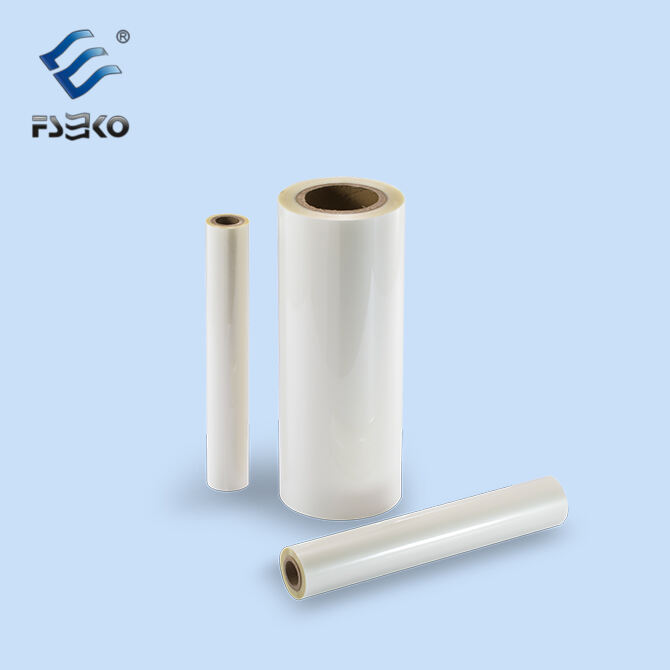

- Width: 300mm, 600mm, customized

- Length: 100m, 200m, customized

- Laminating temp: 160℃

- Overview

- Specification

- Advantages

- End-To-End Customer Support

- After-sales service

- Recommended Products

Product description:

DTF transfer paper is an eco-friendly alternative to traditional DTF transfer film, serving the same functional role in digital transfer printing with a greater focus on sustainability. Like DTF film, it serves as a carrier for designs printed with pigmented inks and thermoplastic adhesive powders, which are then applied to substrates such as textiles using heat and pressure. However, DTF paper is unique in that it is plastic-free, recyclable, and biodegradable, making it an ideal choice for environmentally conscious businesses and consumers.

Specification:

|

Product name |

DTF transfer paper |

|

Gram weight |

70g/㎡ |

|

Width |

300mm, 600mm, customized |

|

Length |

100m, 200m, customized |

|

Laminating temp. |

160℃ |

|

Laminating time |

5~8 seconds |

|

Place of origin |

Guangdong, China |

Advantages:

- Environmentally Friendly Materials:

It is made from renewable and biodegradable resources, such as paper-based substrates, rather than plastic film, reducing its environmental impact.

- Fully Recyclable:

It can be recycled through standard paper recycling processes, contributing to the circular economy.

- Reduced Carbon Footprint:

The production process produces fewer greenhouse gas emissions than petroleum-based plastic film.

- No Plastic Waste:

Eliminates microplastic pollution and the long-term waste associated with synthetic film.

- High Compatibility:

Compatible with the same printing processes, inks, and adhesives as traditional DTF film.

- Excellent Print Results:

Maintains sharp details, vibrant colors, and strong adhesion comparable to plastic-based film.

End-To-End Customer Support:

Customized Film Solutions:

Solve Your Specific Pain Points

Edge warping of heat-intolerant printing materials after laminating

SOLUTION:LowTemperature Thermal Lamination Film

Delamination of digital toner printings after laminating

SOLUTION:Digital Thermal Lamination Film

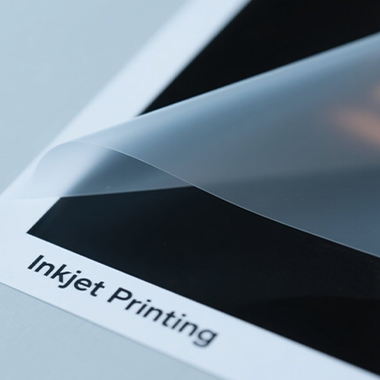

Low adhesive of inkjet printings after laminating

SOLUTION:Thermal Lamination Film for Inkjet Printing

Solution:

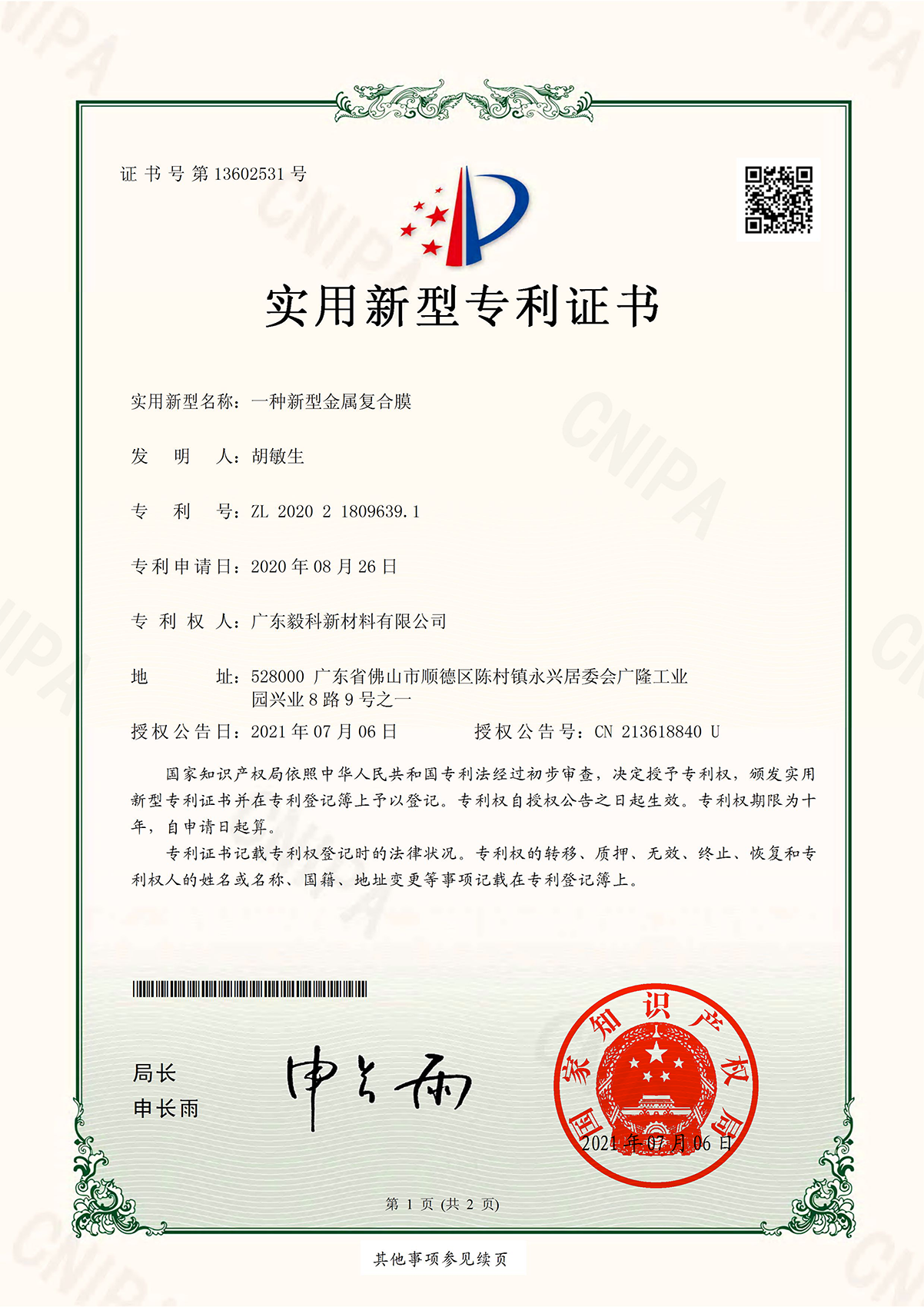

Deep Cooperation with School's Research Department Delivering Customized Solution

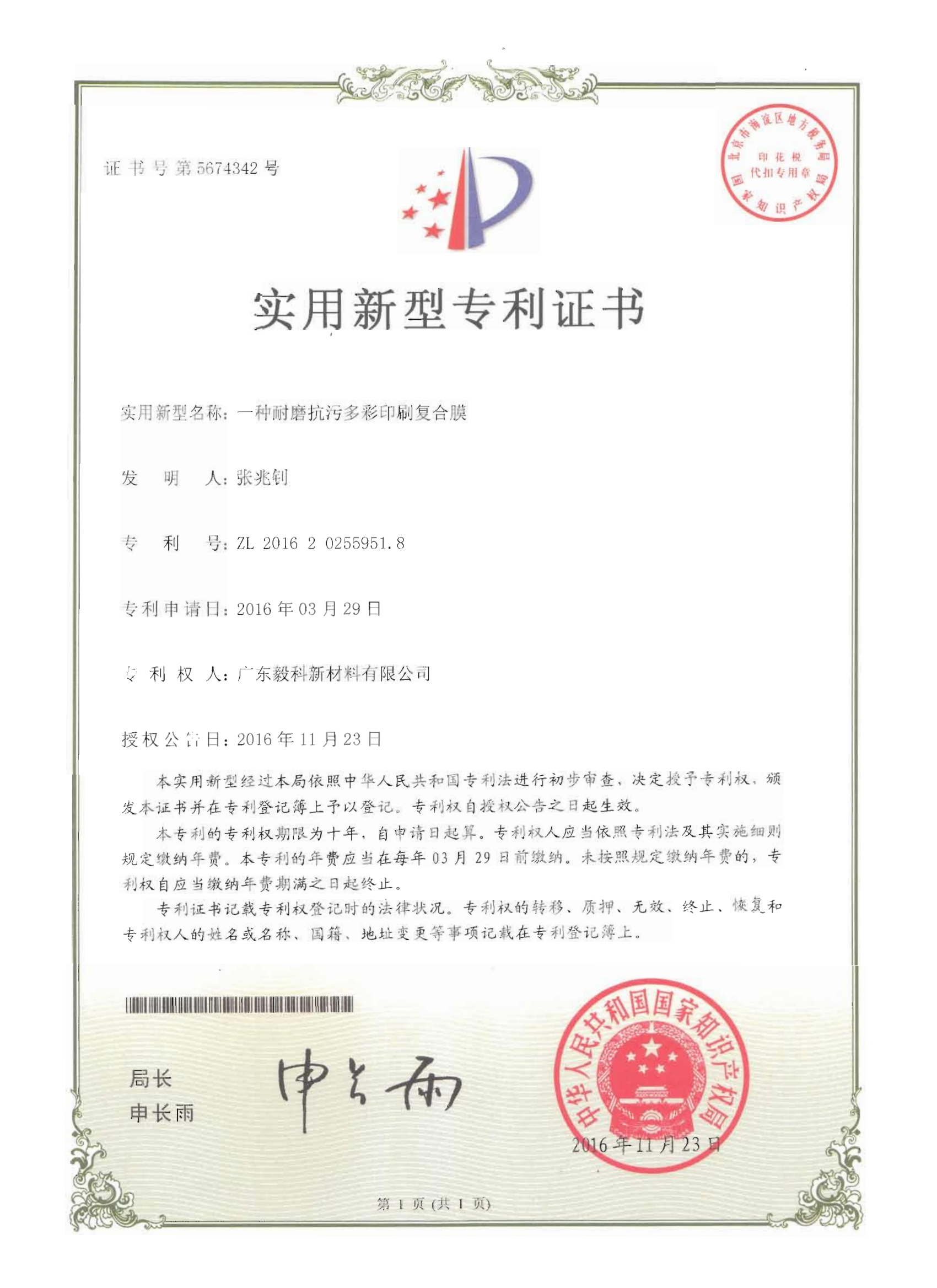

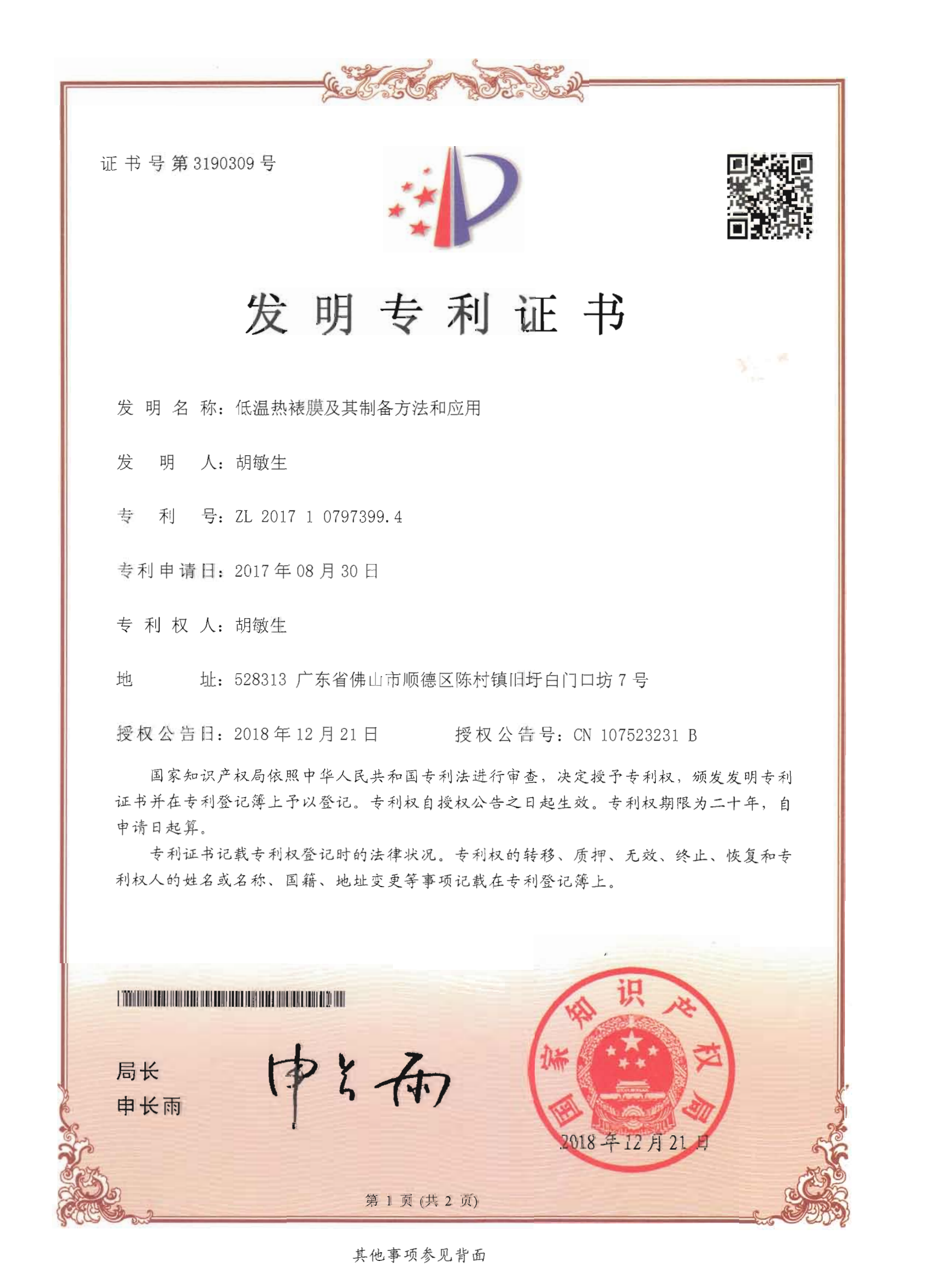

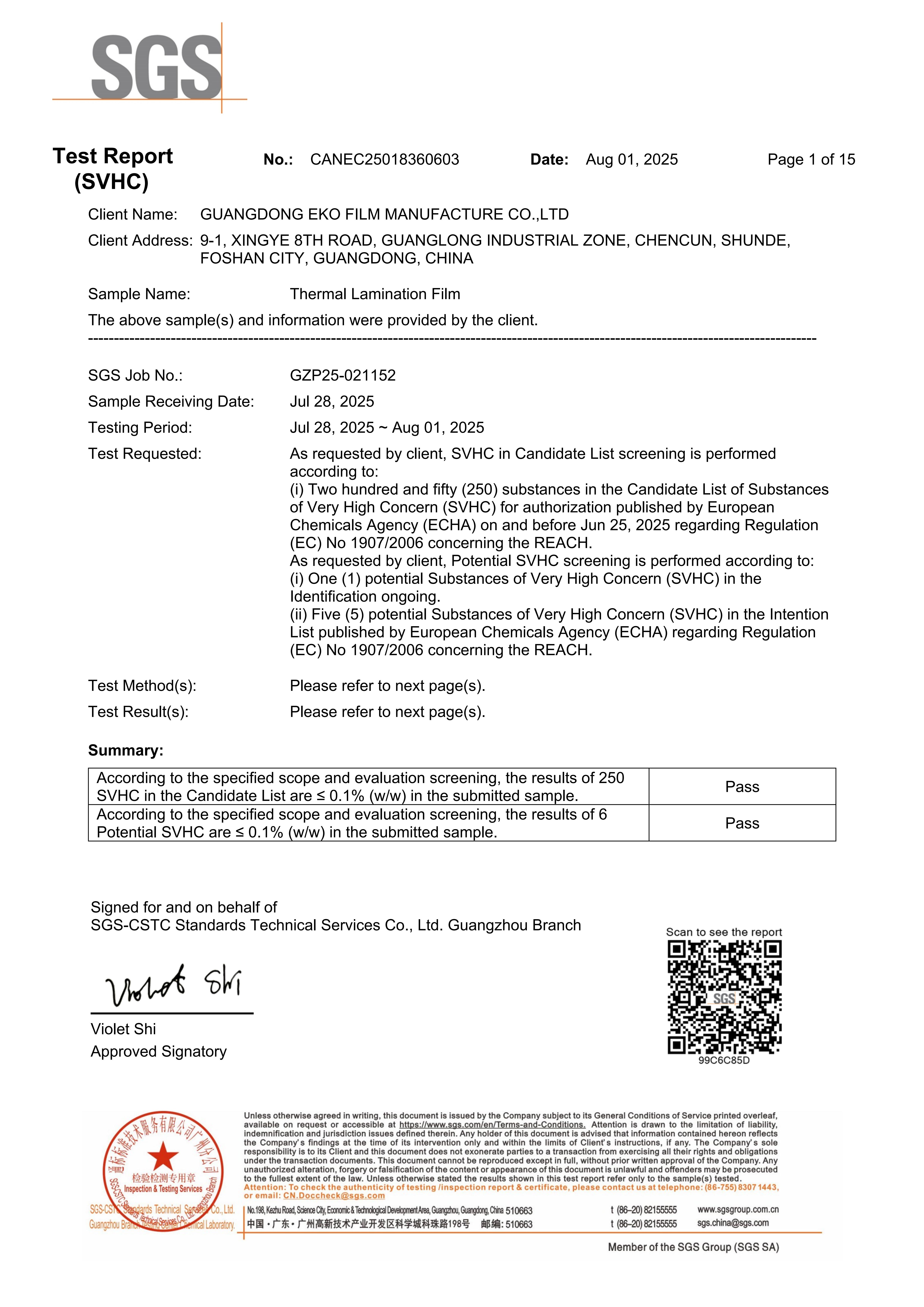

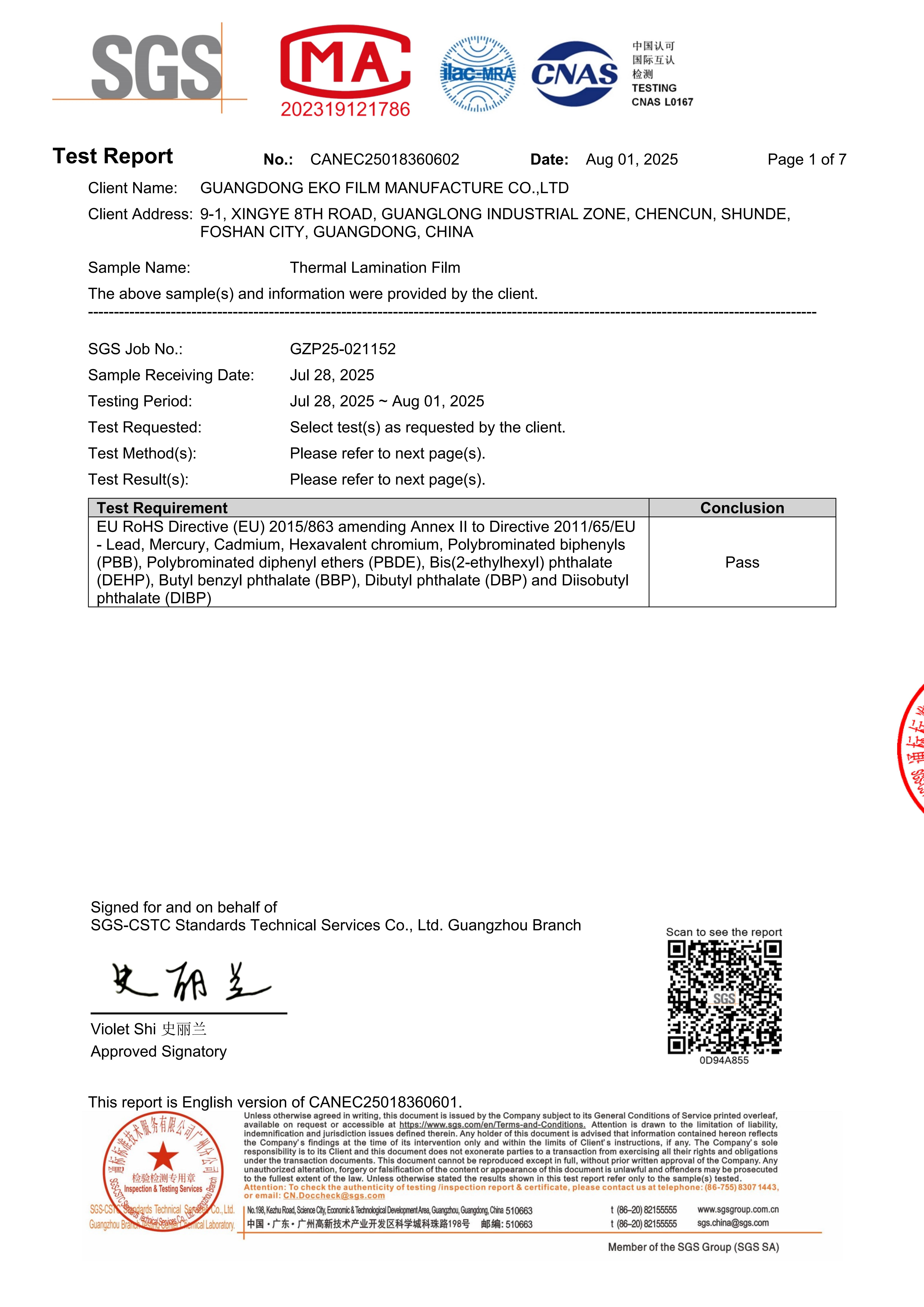

Compliance:

RoHS & REACH & Food Contact Material Triple-Certified

After-sales service:

For product problems, please provide us with photos or videos for our reference. Our after-sales service department will try our best to help to solve. For technical support, we welcome you to send us your product samples and discuss with our professional technical support team. Your feedback is valuable to us.

Packaging & Shipping:

FAQ:

Q1:Are you a factory or a trading company?

A: We are a company integrating R&D, production and sales.

Q2: How do you ensure the quality of your products?

A: We do end-to-end quality control-real time thickness check, corona value detection, bond strength testing, performance packaging.

Q3: What is your main products?

A: EKO has a broad product portfolio by catering to a wide range of industry needs, including BOPP thermal lamination film, digital super sticky thermal lamination film, thermal lamination film for inkjet printing, digital toner foil, DTF film & paper, heat sealable film, etc..

Q4: Can I get some samples or trial order for trying?

A: Yes, we provide free samples, the sample size is 320mm*30m per roll. You only need to pay for the shipping cost.

Q5: What services can we get?

A: We provide end-to-end customer support including professional customer service, customized solution, free samples, trial order, product information pack, technical consulting, full logistics tracking and feedback, comprehensive customer complaint process.

Q6: What payment terms do you offer?

A: We offer EXW, FOB, CIF, DAP, DDP, etc..