What Is Soft Touch Lamination Film?

Definition and Basic Composition

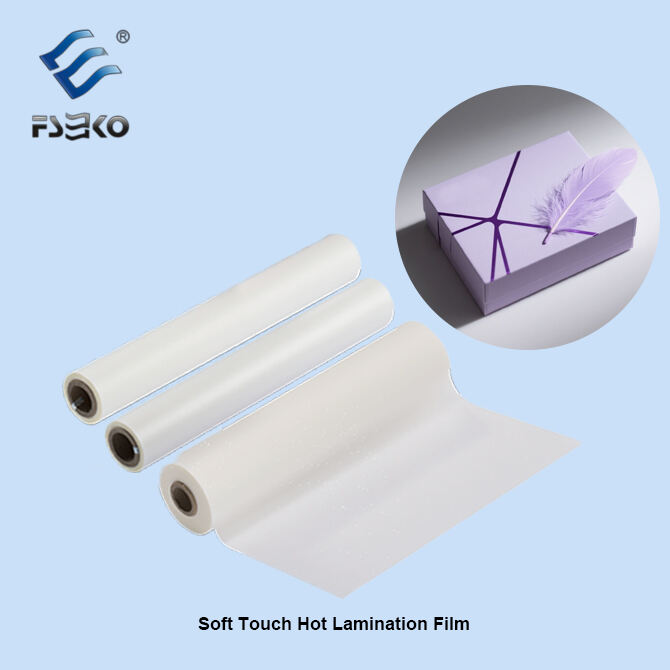

Soft touch lamination film consists of polypropylene or polyester layers mixed with special additives that create that distinctive feel. When heat applied during production bonds these films to materials such as cardboard or thick paper, they develop that signature matte finish everyone loves for how it feels in hand while still standing up against smudges and scuffs. Compared to regular shiny laminations, products finished this way just look and feel more premium. The market has seen significant improvements lately thanks to better formulas and manufacturing techniques that make this option both practical and appealing for packaging and promotional materials alike.

How Soft Touch Lamination Differs from Standard Laminates

Regular laminates usually come in shiny or dull finishes, all about how things look instead of how they feel to the touch. Soft touch lamination is different though. It creates this really nice texture that feels kind of like velvet but doesn't pick up fingerprints easily. People actually enjoy touching these surfaces, which is why we see them so much in fancy product boxes and premium brochures where customers might run their hands over the material. Most traditional coatings just focus on lasting forever without thinking about comfort. But soft touch options manage to protect whatever's underneath while still giving that luxurious feel when someone handles it. That combination of practicality and pleasant sensation really stands out in the market today.

Key Benefits of Using Soft Touch Lamination Film

Enhanced Tactile Experience and Aesthetic Appeal

Soft touch lamination gives surfaces that velvety feel similar to suede, creating a direct physical connection when someone touches it. This makes regular items suddenly feel really premium to the hand. Works especially well on fancy product boxes and promotional materials too. The coating cuts down on shiny reflections and stays clean longer since fingerprints don't show as much, so things look good whether under bright lights or dimmer conditions. According to some studies from Packaging Digest back in 2023, products with these kinds of textured finishes actually make people want to buy them about 23% more often for upscale goods. And companies that switched to soft touch options saw their customers remember their brand around 34% better than those sticking with standard glossy coatings. Makes sense why so many high end brands are jumping on board with this approach lately.

Durability, Scratch Resistance, and Protective Qualities

Soft touch lamination does more than just look good on paper products. The actual protection it offers is pretty impressive too. Most laminates have around 2 to 3 mils of polyester that acts as a shield against everyday wear and tear. This includes scratches from fingers, dampness from coffee spills, and even damage from sunlight exposure. Printed materials with this kind of protection can last almost twice as long when placed in tough spots like busy retail stores. How does it work? The bonding happens through heat, creating a smooth yet bendy cover that won't crack when folded multiple times. Think about restaurant menus that get flipped through hundreds of times daily or product samples handed out at trade shows. According to tests run by Material Durability Institute back in 2022, laminated surfaces hold up about four times better against rubbing and scraping compared to regular prints without any coating.

Brand Perception and Market Differentiation

According to recent consumer surveys, products with soft touch finishes can boost their perceived value by around 28%. That's why many companies in competitive sectors such as cosmetics and tech gadgets are now incorporating these finishes into their designs. The subtle luxury aspect helps justify those higher price tags too. Brands often manage to charge between 15% and 20% more when they use this kind of finish on their products. These days, everything seems to be going towards minimalism in design, so having something that feels exclusive and sophisticated makes all the difference. Most marketing professionals agree on this too - roughly 67% say that adding texture through special finishes is absolutely necessary if they want their products to stand out from the crowd in crowded marketplaces. This insight comes straight from the latest Branding Trends Report published back in 2023.

Common Applications Across Industries

Packaging for Luxury Goods and Cosmetics

Luxury packaging often features soft touch lamination because it offers both a pleasant feel and understated looks that scream premium quality. According to the latest Packaging Trends Report from 2023, around seven out of ten shoppers link these matte finishes with better quality products, especially when looking at makeup items or special edition collections. Beyond just making things look good, this type of coating actually makes the unboxing experience nicer for customers. Plus there's another benefit no one talks about much: packages with soft touch coatings tend to survive shipping better than their shiny counterparts. Some companies have seen their return rates drop by nearly 30% after switching from glossy to soft touch laminates, mainly because these surfaces resist scratches so much better during transport.

Printed Marketing Materials and Brand Collateral

When it comes to brochures, business cards or product catalogs, adding that soft touch lamination makes all the difference in how people remember a brand. A recent survey from Print Marketing in 2024 found something interesting trade show goers tend to hang onto those matte finish materials about 40% more often than glossy ones. And let's face it, who hasn't dropped a brochure or two? The special film used actually stands up pretty well against oils from hands and even light spills, so these marketing pieces last much longer when they get passed around at events. This durability factor definitely boosts the professional look while keeping information accessible for anyone picking them up throughout the day.

Use in Book Covers, Menus, and Product Labels

Soft touch finishes have become popular among publishers looking to create premium books and restaurants wanting to elevate their menus beyond standard paper stock. According to recent market research published last year by the Print Finishes Association, menus with these special coatings saw customers rate the food quality about 22 percent higher than regular menus. What makes these finishes so useful? They bend easily around curves which means they work great on things like wine bottles and spice jars where moisture is always an issue. The material sticks even when exposed to condensation and doesn't get cloudy over time, something many businesses find really important for maintaining brand image at point of sale.

How to Choose the Right Soft Touch Lamination Film for Your Project

Evaluating Film Thickness and Finish Consistency

The thickness of film really matters when it comes to how things perform. Thinner films around 1.5 to 2 mil keep materials flexible enough for stuff like book covers where bendability is important. Thicker options at 3 to 5 mil offer better durability needed for rigid packaging applications. According to industry numbers from Brillpack back in 2023, laminating generally costs somewhere between ten cents and twenty cents per square foot. Testing actual samples in realistic situations remains essential though. Look closely at texture consistency and surface sheen during these tests because even small variations will make that premium look fall flat instead of standing out.

Compatibility with Printing Methods and Substrates

Soft touch lamination works really well with both offset and digital prints, keeping the ink looking sharp and preventing any smudges. Works great on uncoated paperboard and those synthetic materials too, although sometimes we need to apply some primer first to get the best possible bond. Don't try putting it on glossy surfaces though because that just ruins the nice matte feel people want. And if working with special inks like metallics or those UV stuff, make sure everything is fully cured before laminating otherwise there's a good chance of things coming apart later on.

Sustainability and Eco-Friendly Options

Sustainable options include films containing 30â€50% recycled content or those certified under FSC⢠and ISO 14001 standards. Biodegradable PLA-based alternatives are increasingly adopted for food-safe and disposable packaging. With 62% of brands prioritizing eco-friendly materials in redesigns (2023 industry survey), requesting full sustainability documentation from suppliers is a best practice for responsible sourcing.

FAQ

What is soft touch lamination film made of?

Soft touch lamination film is typically made from polypropylene or polyester layers combined with special additives that create its distinctive texture.

How does soft touch lamination differ from standard laminates?

Soft touch lamination provides a velvety feel and is resistant to fingerprints, unlike standard laminates which are typically shiny and focus more on appearance than texture.

What are the benefits of using soft touch lamination film?

Soft touch lamination enhances tactile experience, offers aesthetic appeal, provides durability and scratch resistance, and improves brand perception with a sense of luxury.

Where is soft touch lamination commonly used?

This lamination is commonly used in luxury packaging, printed marketing materials, and for book covers and menus.

How to choose the right soft touch lamination film?

It is important to consider the film thickness, compatibility with printing methods, and sustainability options when selecting the right lamination film for your project.