DTF ස්ථානාන්තර පත්රය

- නිෂ්පාදන නාමය: DTF හරවා ගැනීමේ පත්රය

- ඝනකම: 75mic

- පළල: 300mm, 600mm, අභිරුචිය

- දිග: 100m, 200m, අභිරුචිකරණය කර ඇත

- ලැමිනේෂන් උෂ්ණත්වය: 160℃

- දළ විශ්ලේෂණය

- විස්තර

- වටිනාකම

- අවසානය සිට අවසානය දක්වා පාරිභෝගික සහාය

- ආකෘතිය පසුව සේවා

- නිර්දේශිත නිෂ්පාදන

නිෂ්පාදන විස්තරය :

DTF ස්ථානාන්තර පත්රය ඩිජිටල් මුද්රණය සඳහා විශේෂයෙන් නිර්මාණය කරන ලද ස්ථානාන්තර මාධ්යයක් වන අතර, විවිධාකාර පෘෂ්ඨීය තල, විශේෂයෙන් ඇඳුම් ද්රව්ය මත ඉහළ විභේදන සහිත නිර්මාණ ප්රතිනිර්මාණය කිරීම සඳහා භාවිතා වේ. මෙම ක්රියාවලිය රූපය පාට ඉන්ක් භාවිතයෙන් පත්රය මත මුද්රණය කිරීම, උෂ්ණත්වයෙන් දැල්වෙන පොලිමර් පවුඩරයක් යෙදීම සහ අවසානයේ ඉලක්කගත ද්රව්යය මත රූපය අදින සඳහා උෂ්ණත්වය යෙදීම ඇතුළත් වේ. සාම්ප්රදායික ක්රම වලට වෙනස් ලෙස, DTF තාක්ෂණය ආලෝකය හා දැඩි වර්ණ ඇති ඇඳුම් ද්රව්ය මත දැවැන්ත, විස්තරාත්මක හා දැරිය හැකි ස්ථානාන්තර සිදු කිරීමට ඉඩ සලසයි, පෙර හෝ පසු සැකසීමේ පියවර අවශ්ය නොවේ.

විස්තර :

|

ප්රෝඩัก්ට් නම |

DTF ස්ථානාන්තර පත්රය |

|

ඝණකම |

මයික් 75 |

|

පළල |

300mm, 600mm, අභිරුචිකරණය කළ හැක |

|

දිග |

මීටර් 100, මීටර් 200, අභිරුචිකරණය කර ඇත |

|

ලැමිෙන්ටින් උෂ්ණත්වය. |

160℃ |

|

ලැමිෙන්ටින් කාලය |

තත්පර 5-8 |

|

ආරම්භ ස්ථානය |

චීන, ග්වැඕන්ද් |

වටිනාකම :

- පුළුල් යෙදීම:

පත්ති, පොලිඑස්ටර් සහ මිශ්රණ ඇතුළු ද්රව්ය පුළුල් පරාසයකට යෙදිය හැක.

- දැවැන්ත වර්ණ ප්රතිනිර්මාණය:

අඳුරු ඇඳුම් වල දී පවා හොඳ වර්ණ පැහැදිලි බවක් සහිතව සම්පූර්ණ වර්ණ සහ ඉහළ විභේදන ප්රතිරූප සහාය දක්වයි.

- කෘෂ්ණ සහ දැරිය හැකි අවසාන ආවරණය:

පැළෑටි, ඇදීම සහ රගිළීමෙන් තොරව සැලීම සහ පැළෑටි නොවැටී ස්ථිර ආරක්ෂිත පෙළක් නිපදවයි.

- පූර්ව ප්රතික්රියා අවශ්ය නැත:

ඇඳුම් පූර්ව ආලේපනය කිරීමට අවශ්ය නැත (DTG මුද්රණය මෙන් නොව), එමඟින් නිෂ්පාදන කාලය සහ පිරිවැය අඩු කරයි.

- කාර්යක්ෂම කෙටි-චලන නිෂ්පාදනය:

අවම සැකසීමේ අවශ්යතා සහිතව, අභිරුචි ඇණවුම්, ප්රාතිරූප සහ අඩු සිට මධ්යම පරිමා නිෂ්පාදන සඳහා අනුකූල වේ.

- ඉහළ දැරිය හැකි බව:

මඳක් අඳුරු වීම, පැළෑටි වීම සහ සැලීමෙන් හානි වීමට ඔරොත්තු දෙයි, දිගු කාලීන මුද්රණ ගුණාත්මකභාවය සහතික කරයි. - පරිශීලක මිත්ර ක්රමය:

ජෙට් මුද්රණ යන්ත්ර බහුතරයක් සහ සාමාන්ය තාප පීඩන යන්ත්ර සමඟ අනුකූල වන අතර, කුඩා ව්යාපාර සහ ක්රීඩකයන් සඳහා සුදුසුය.

අවසානය සිට අවසානය දක්වා පාරිභෝගික සහාය :

අභිරුචිකරණය කළ පටල විසඳුම් :

ඔබගේ නිශ්චිත ගැටළු විසඳන්න

ලිපින කිරීමෙන් පසු උෂ්ණත්වයට ඔරොත්තු නොදෙන මුද්රණ ද්රව්ය වල කෙළවර වක්ර වීම

විසඳුම: අඩු උෂ්ණත්වයේ තාප පත්රලේපන පත්රය

ලිපින කිරීමෙන් පසු ඩිජිටල් ටෝනර් මුද්රණ වල ස්තර අඩු වීම

විසඳුම: ඩිජිටල් තාප පත්රලේපන පත්රය

ලිපින කිරීමෙන් පසු ඉන්ක්ජෙට් මුද්රණ වල ඇලීමේ ශක්තිය අඩු වීම

විසඳුම: ඉන්ක්ජෙට් මුද්රණය සඳහා තාප පත්රලේපන පත්රය

විසඳුම :

රෙහිබව් සහිත පාසල් පර්යේෂණ දෙපාර්තමේන්තු සමඟ ගැඹුරු සහයෝගීතාවක් තුළ කාර්යයට අභිරුචි විසඳුම් සැපයීම න

අනුකූලතාව :

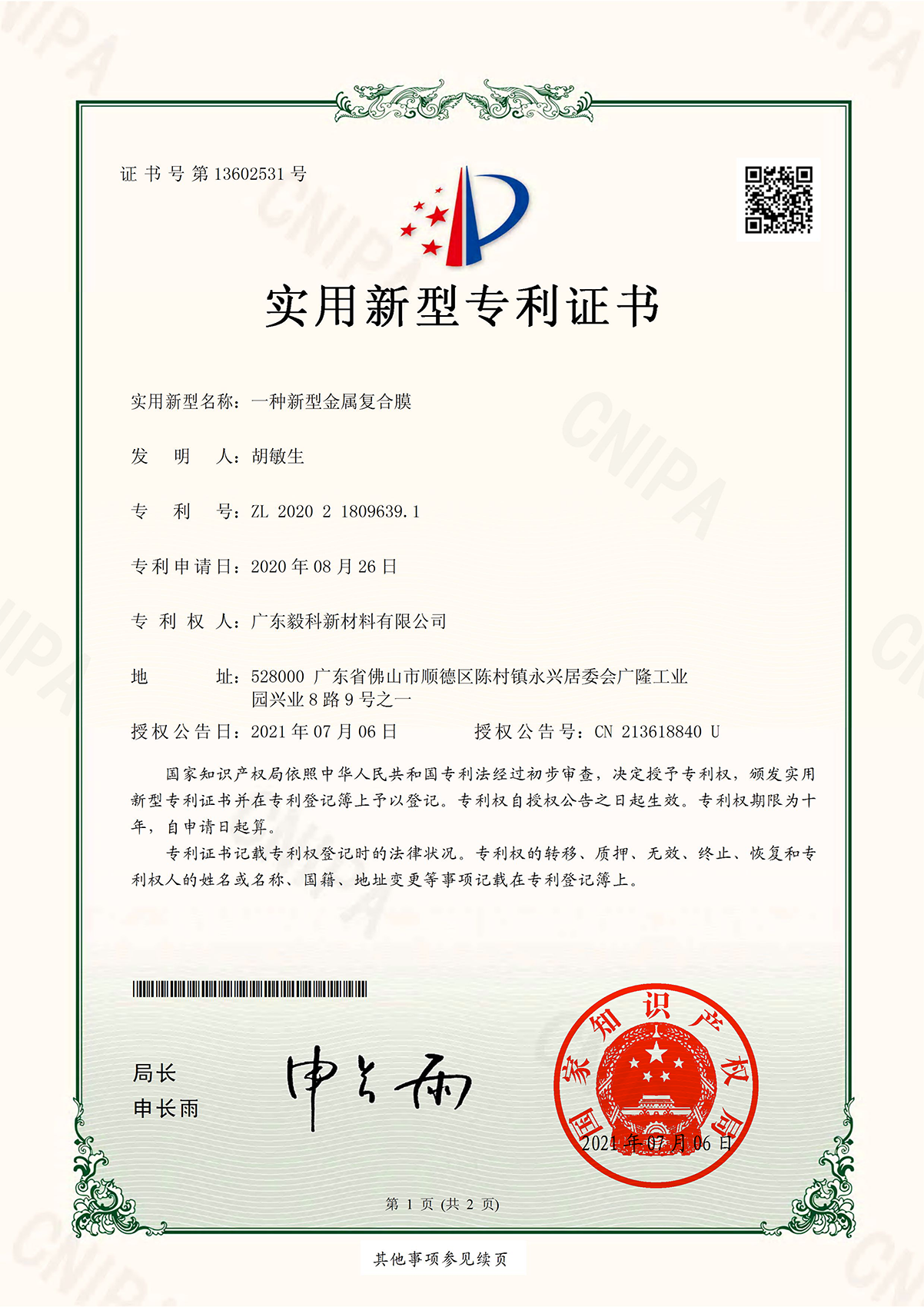

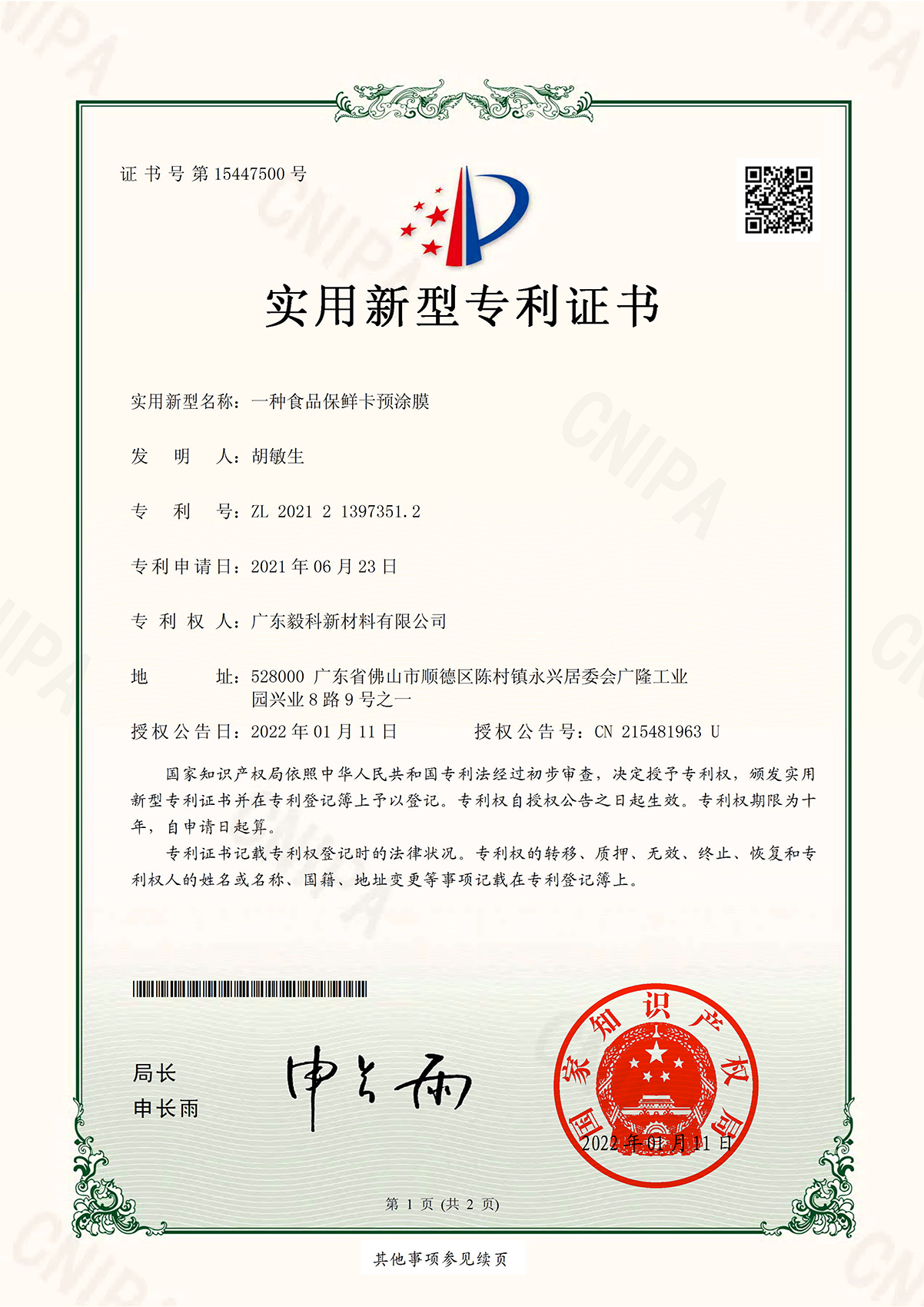

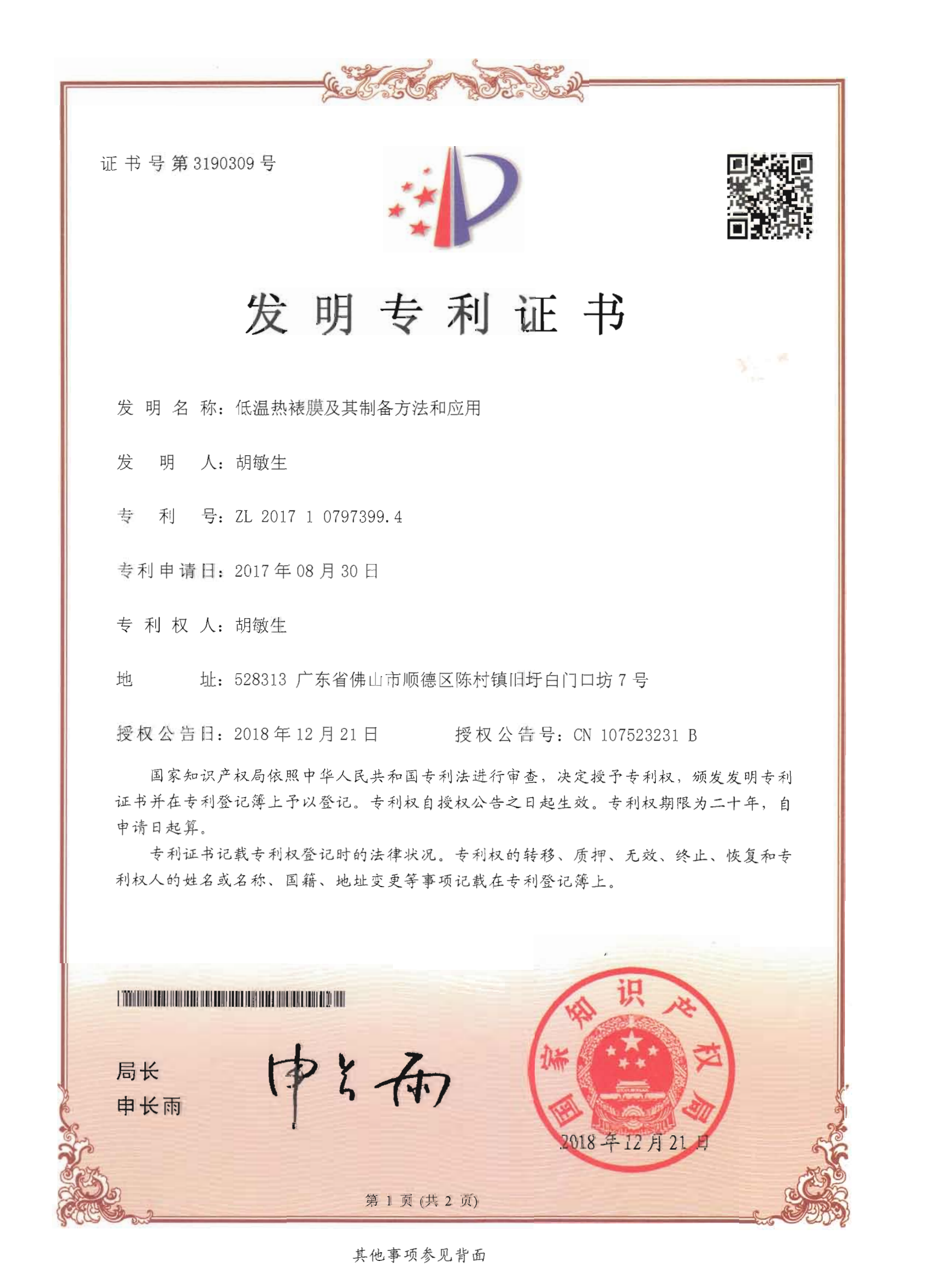

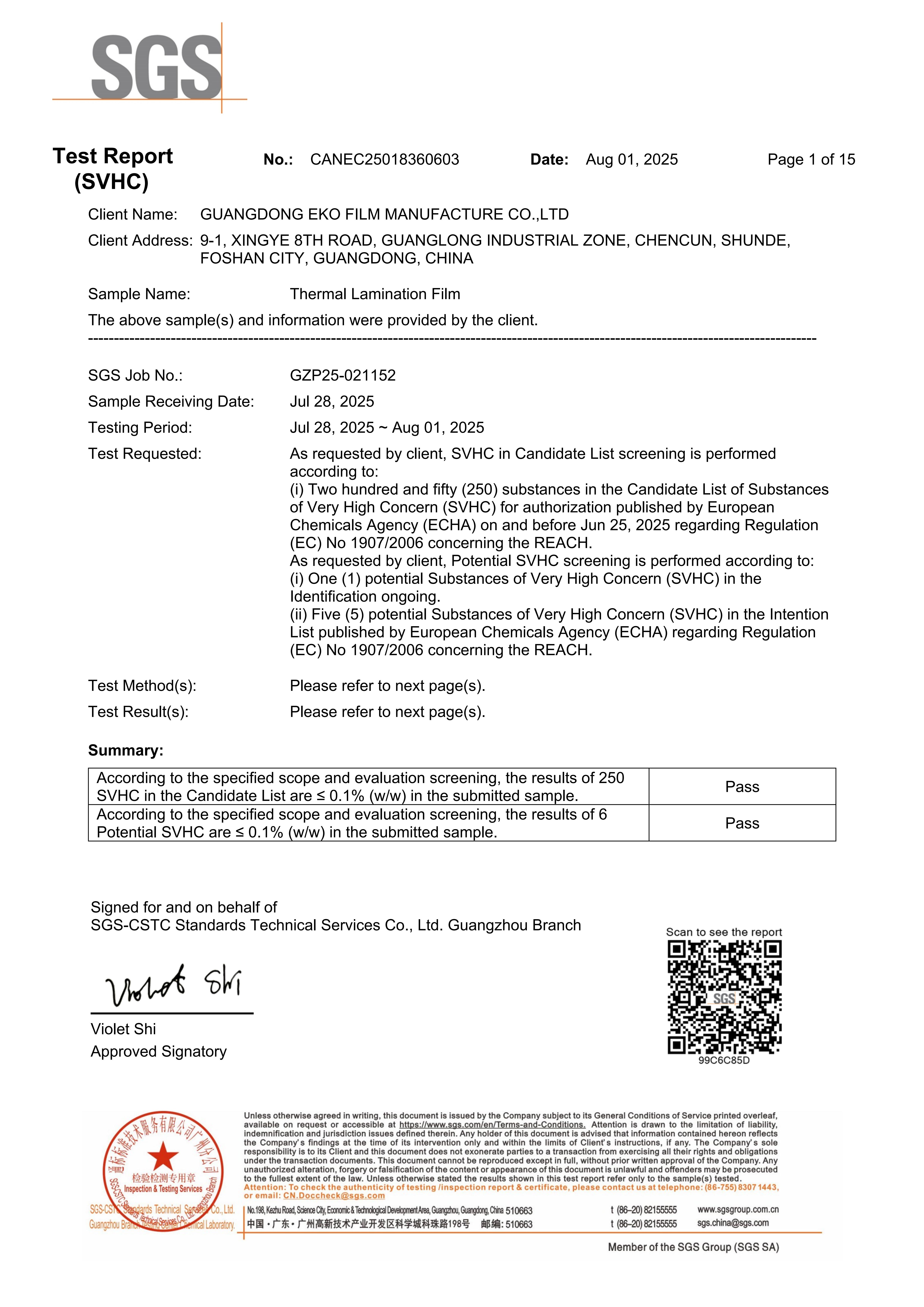

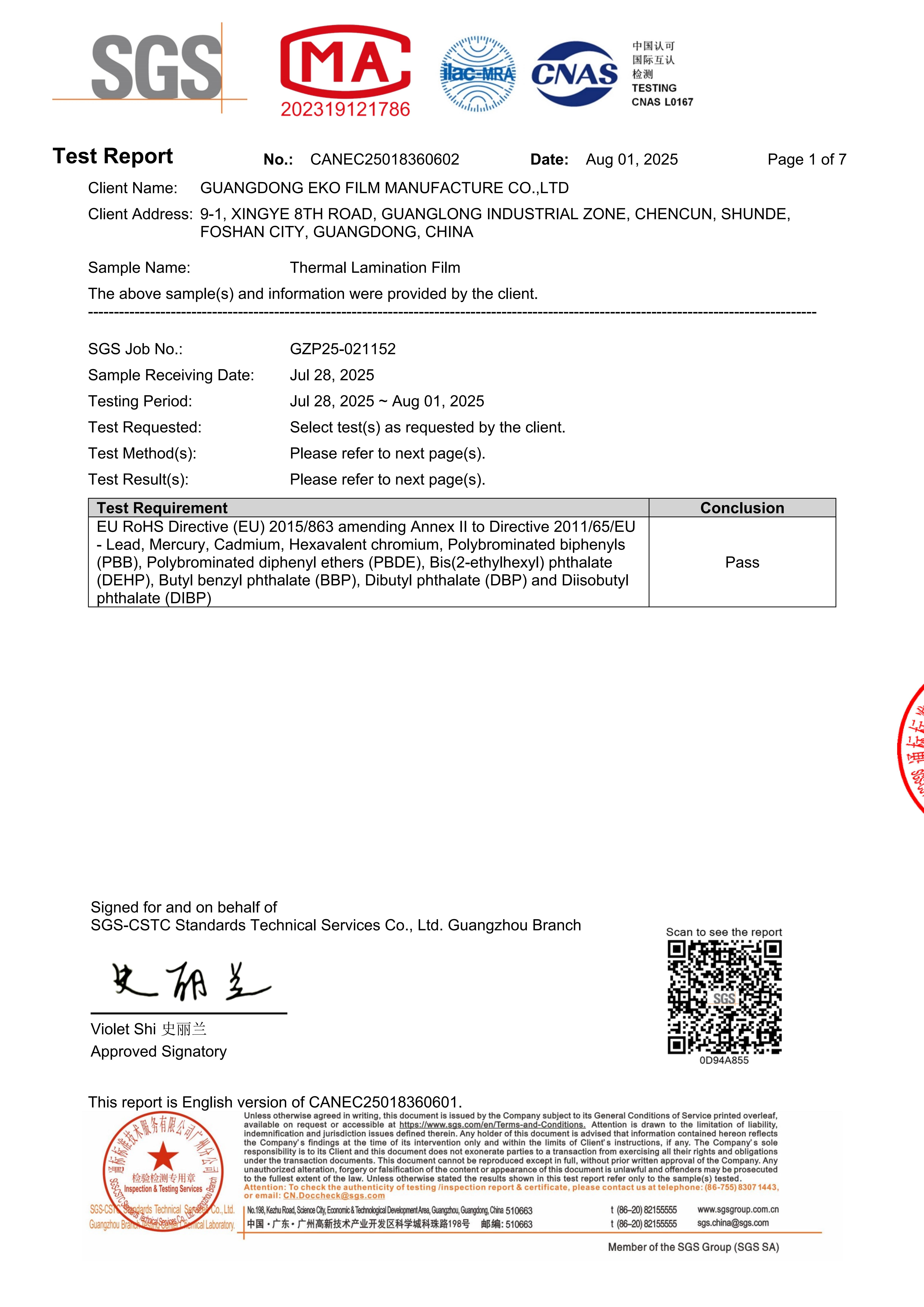

RoHS & REACH & හාර සම්බන්ධ ද්රව්ය ත්රිත්ව-සහතික කිරීම

ආකෘතිය පසුව සේවා :

නිෂ්පාදන ගැටළු සඳහා, කරුණාකර අප වෙත දැක්වීම සඳහා ඡායාරූප හෝ දෘශ්ය පටිගත කිරීම් සැපයිය යුතු අතර, අපගේ පසු-විකුණුම් සේවා දෙපාර්තමේන්තුව එය විසඳීම සඳහා උපරිම උත්සාහයක් දරයි. තාක්ෂණික සහාය සඳහා, ඔබගේ නිෂ්පාදන නියැදි අප වෙත යවා, අපගේ වෘත්තීය තාක්ෂණික සහාය කණ්ඩායම සමඟ සාකච්ඡා කිරීමට ඔබ සාදරයෙන් පිළිගනිමු. ඔබගේ ප්රතිපෝෂණය අප සඳහා අතිශය වටිනා වේ.

පාකින්ග් & සාම්ප්රේතනය :

FAQ :

Q1: ඔබ කර්මාන්ත ශාලාවක් ද, නැතහොත් වෙළඳ සමාගමක් ද?

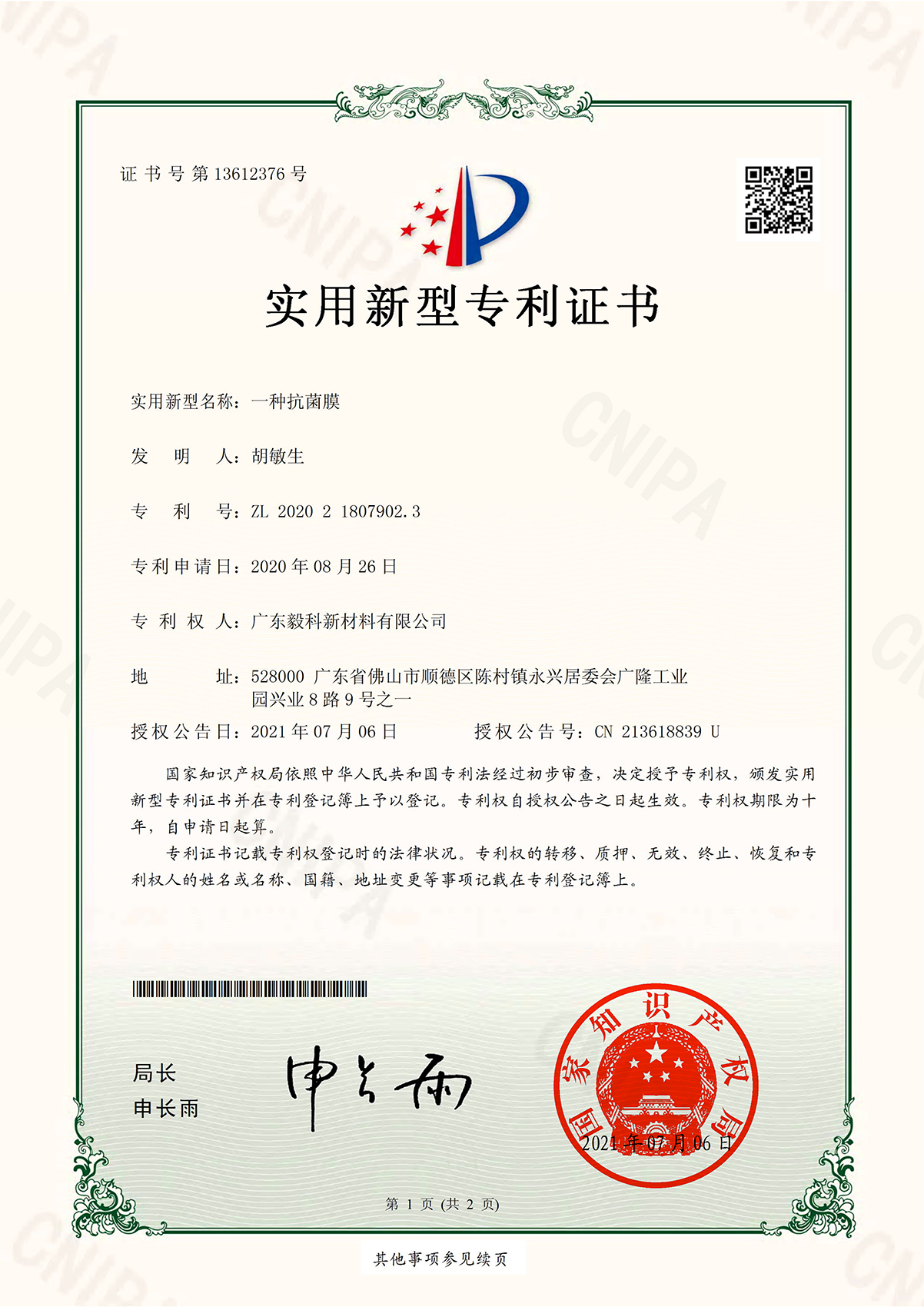

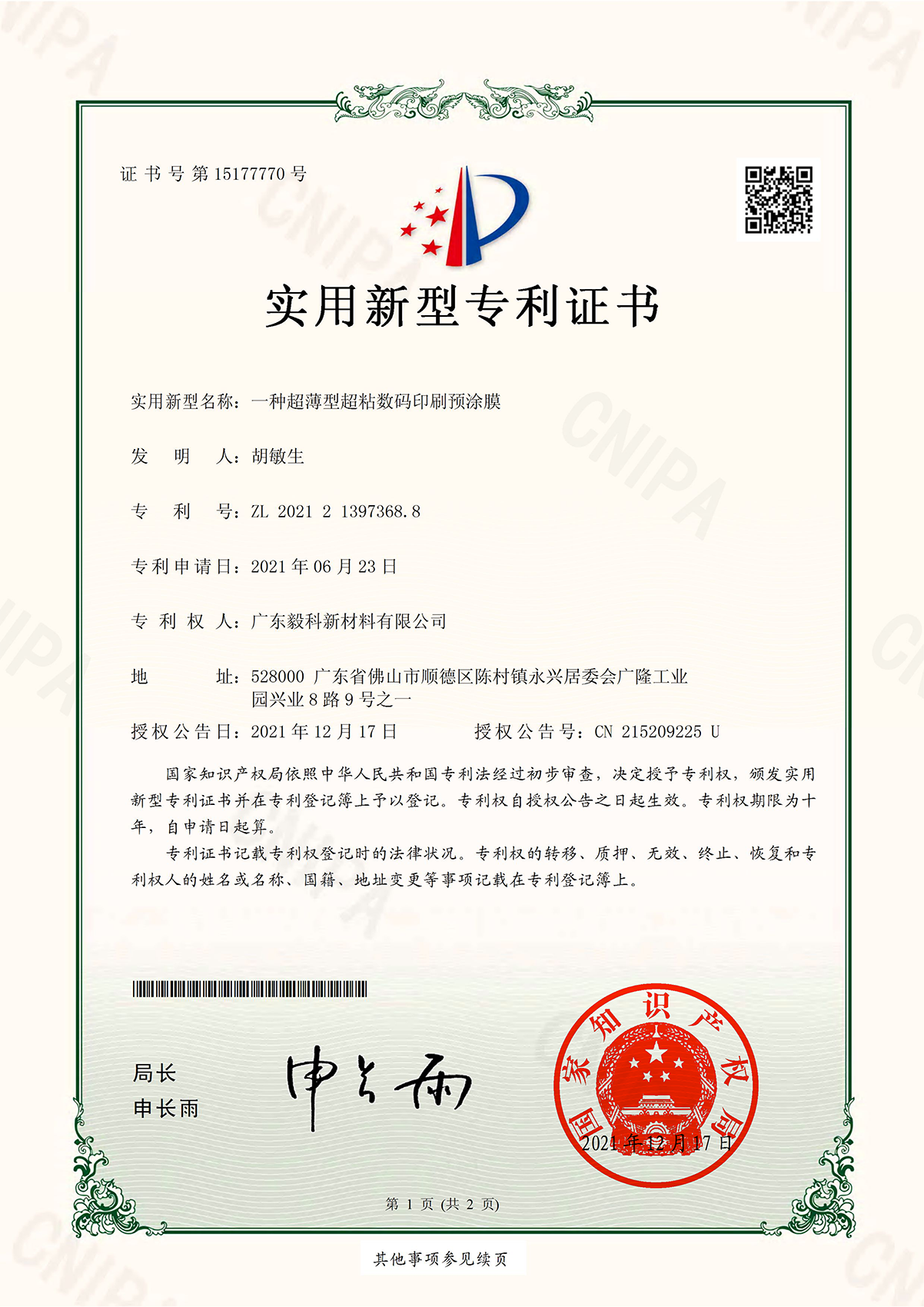

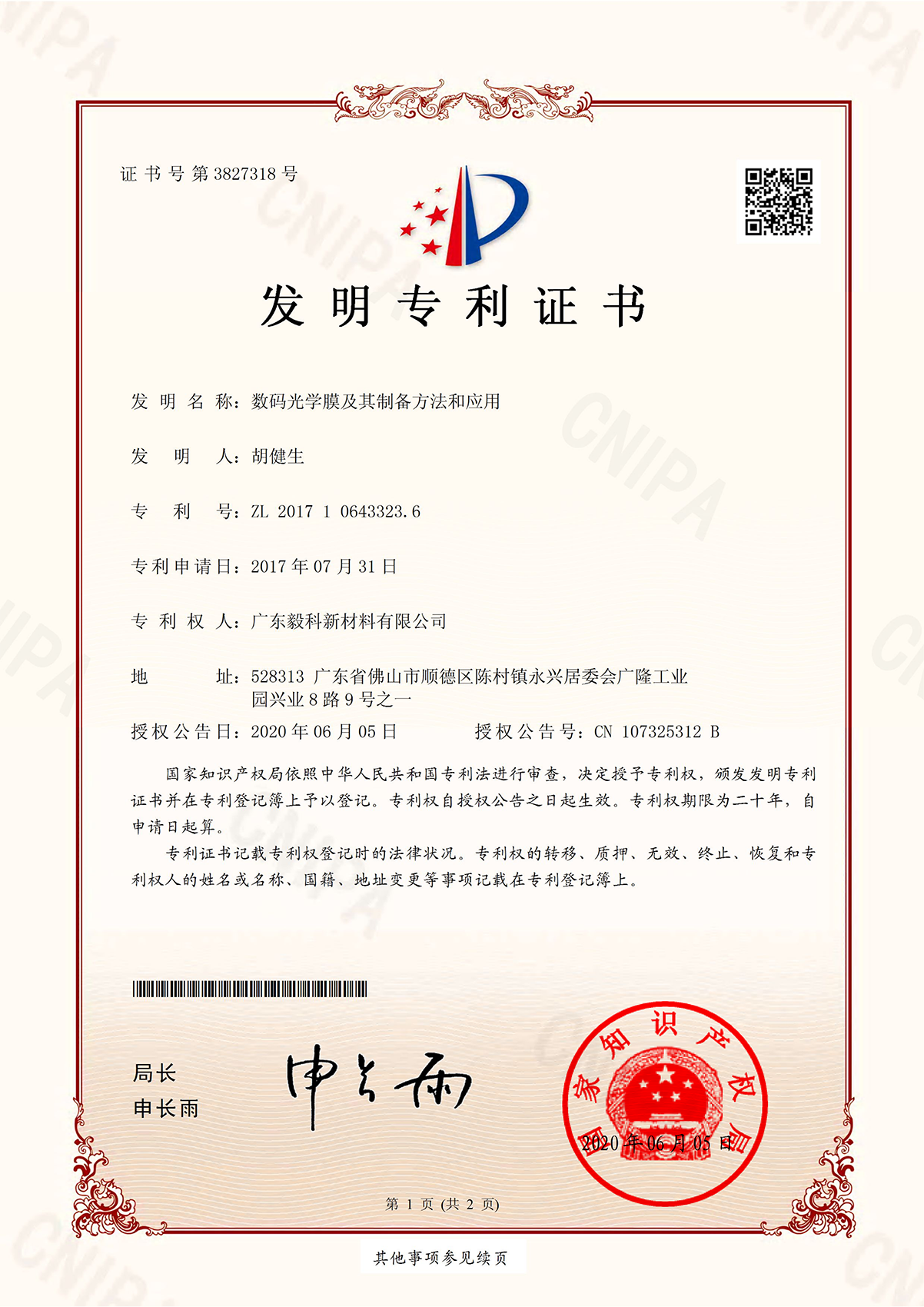

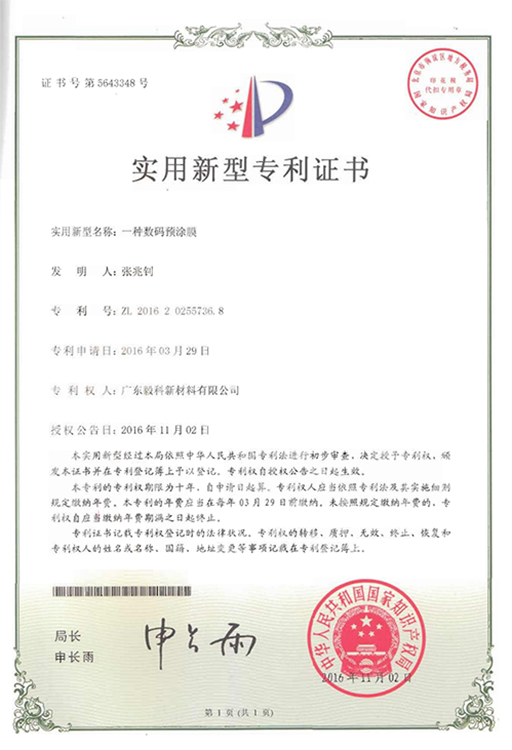

A: අපි R&D, නිෂ්පාදන හා විකුණුම් ඒකාබද්ධ කරන සමාගමකි.

Q2: ඔබේ නිෂ්පාදනවල ගුණාත්මකභාවය ඔබ කෙසේ සහතික කරයි?

A: අපි අවසන් දක්වාම ගුණාත්මකභාවය පාලනය කරමු - තාත්වික කාලයේ ඝනත්වය පරීක්ෂා කිරීම, කොරෝනා අගය හඳුනා ගැනීම, බන්ධන ශක්තිය පරීක්ෂා කිරීම, ක්රියාකාරී ඇසුරුම් කිරීම.

Q3: ඔබේ ප්රධාන නිෂ්පාදන මොනවාද?

A: EKO හට BOPP තාප චිත්රපට ආලේපන පටිය, ඩිජිටල් ඉතා අල්ලා ගන්නා තාප චිත්රපට ආලේපන පටිය, ඉන්ක්ජෙට් මුද්රණය සඳහා තාප චිත්රපට ආලේපන පටිය, ඩිජිටල් ටෝනර් පත්රය, DTF පටිය හා කෙස්ස, උණුසුම් සීල් කළ හැකි පටිය ඇතුළු විවිධ ක්ෂේත්රවල අවශ්යතා සපුරාලන පරාසයක් ආවරණය කරන පුළුල් නිෂ්පාදන ප්රවාහයක් ඇත.

Q4: මට සාම්පල හෝ පරීක්ෂණ ඇණවුමක් ලබා ගැනීමට හැකිද?

ඇ: ඔව්, අපි නොමිලේ නියැදි සැපයුම් කරන අතර, නියැදි ප්රමාණය රෝලයකට 320mm*30m ක් වේ. ඔබ ගාස්තු දිය යුත්තේ ගාස්තු පමණි.

Q5: අපිට ලබා ගත හැකි සේවා මොනවාද?

ඇ: අපි වෘත්තීය පාරිභෝගික සේවා, කැමැති පරිදි සැකසූ විසඳුම, නොමිලේ නියැදි, පරීක්ෂණ ඇණවුම, නිෂ්පාදන තොරතුරු පැකේජය, තාක්ෂණික උපදෙස්, සම්පූර්ණ ද්රව්ය ගමන් අඟලනය සහ ප්රතිපෝෂණය, සම්පූර්ණ පාරිභෝගික කැඳුම් ක්රියාවලිය ඇතුළු අවසන් දක්වාම පාරිභෝගික සහාය සැපයුම් කරන්නෙමු.

Q6: ඔබ ඉදිරිපත් කරන ගෙවීමේ කොන්දේසි මොනවාද?

ඇ: අපි EXW, FOB, CIF, DAP, DDP, ආදිය ඉදිරිපත් කරමු.