فیلمی ئەلومنیۆمی PET پێش-پۆلینکراو

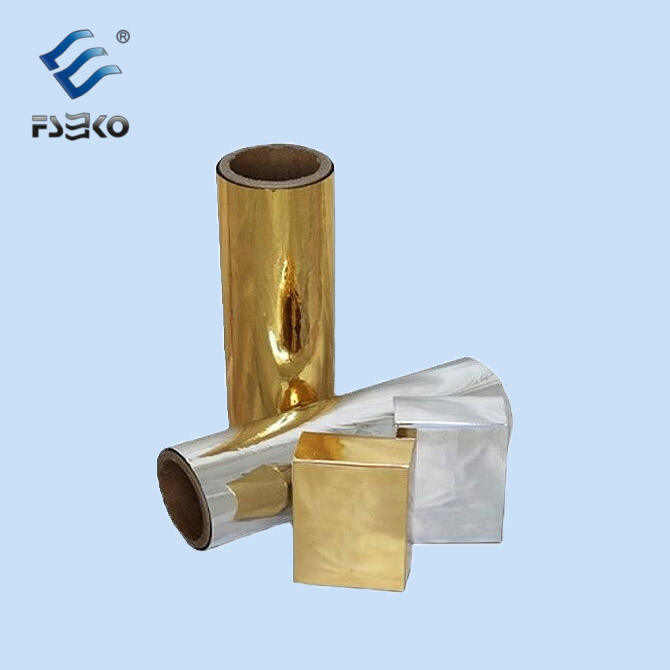

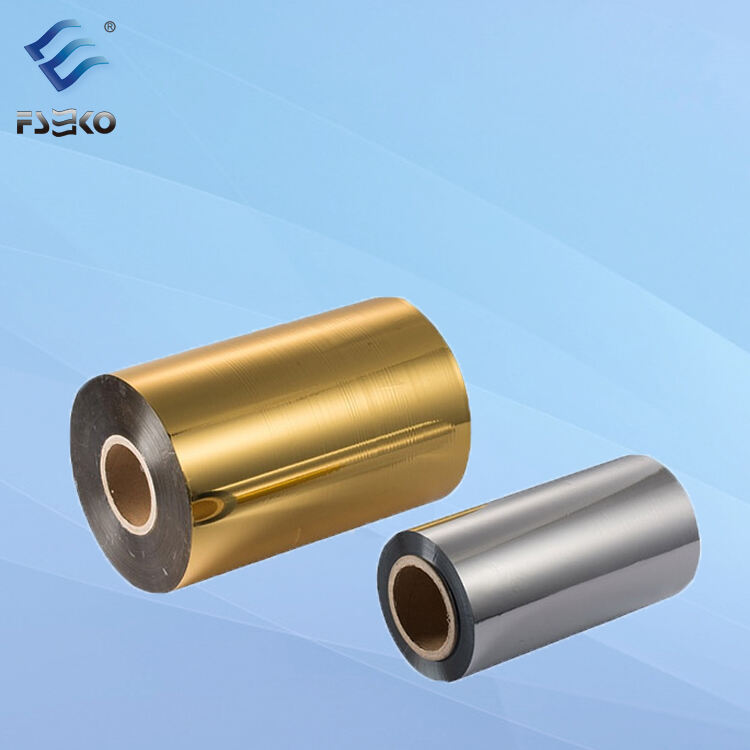

- ناوی بەرهەم: فیلمی ئالیومینیومی PET بەپێشەوە پۆشراو

- Adhesive: EVA

- Rû: Birûskî

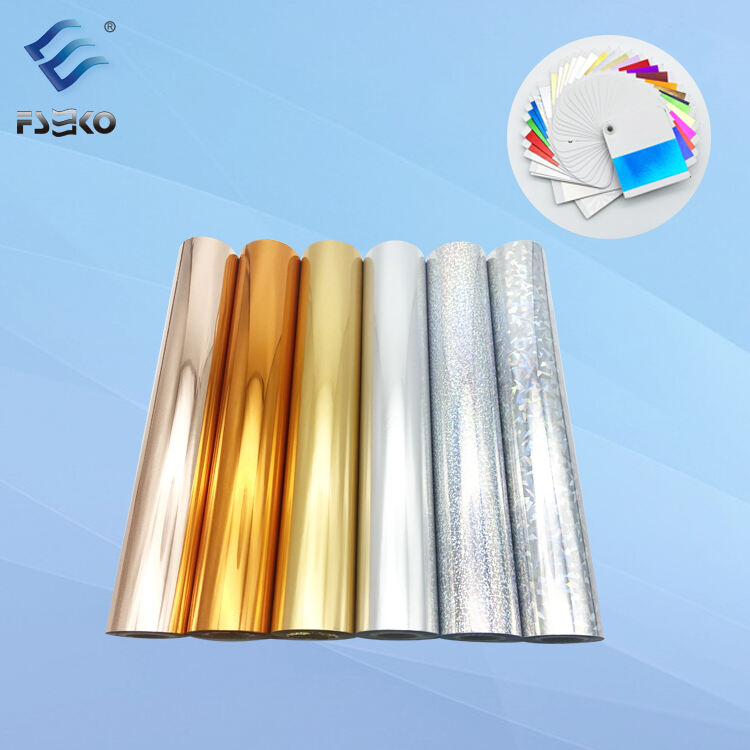

- ڕەنگ: زێڕین، سپی

- Core: 1 inch (25.4mm) / 3 inch (76.2mm)

- Overview

- تایبەتمەندی

- Avantajên

- پشتگیری کڕیار بە درێژایی ڕێک

- Xizmetên piştî firotanê

- Products ya pêşterandinê

Danasnameya Produktê :

فیلمی پێش کۆمەڵکراوی ئالۆمینۆم PET ماددەیەکی زۆر لاوەردانی بەرزە. تەکنیکی دروستکردنی وێنەی متالیکی ناسەری دەبەخشێت، هەروەها لەگەڵ ئەوەشدا ناوبانگ و بەهێزی PET دەمێنێتەوە. فیلمەکە بۆ بەکارهێنان لەگەڵ ئامێری لایمینەیسیۆنی گەرم دروستکراوە، بە بەکارهێنانی گەرمی و فشار فیلمەکە بە شێوەیەکی سەلامەت لەسەر ڕووکاری چاپ دەچووتە ناو، کە هەم بەهێزی دیزاوینی و هەم پاراستنی کارایی دەبەخشێت. فیلمەکە زۆر بەکاردێت لە بواری دابەشکردن، چاپکردن و ناوناندندا بۆ دەستکەوتنی ئەفەکتی متالیکی بڵاو و بەکیفیت.

تایبەتمەندی :

|

ناوی بار |

فیلمی ئەلومنیۆمی PET پێش-پۆلینکراو |

|

Pêvzeliqî |

EVA |

|

Surface |

Birqane |

|

Reng |

Zêr, zîv |

|

Deq |

22 mic |

|

پەیمان |

300mm ~ 1500mm |

|

درێژایی |

200m~4000m |

|

بنەما |

1 inch (25.4mm) / 3 inch (76.2mm) |

|

Paketkirin |

Qutiya jor û jêr / qutiya kartonê |

|

Germahiya laminasyonê. |

110℃~120℃ |

|

Cihê Çavkaniyê |

Guangdong, Çîna |

Avantajên :

- فریاکردنی مەتالیکی باشتر:

ڕووکارێکی بڵاو و بەهێز دروست دەکات کە وەک متالیکی پاکراو دیاری دەکات، کە ئەنجامی دیزاینی بەرھەمەکە زیاد دەکات و بەهای بازاڕی تێچووی بەرھەمەکە زیاد دەکات.

- دەتوانرێت چاکسازی ڕووکار بکرێت:

دەتوانرێت چاپ لەسەر ڕووکاری ئەم فیلمە بکرێت و دەربڕینی گەرمیش بکرێت، کە ئەنجامی ڕووکاری زیاتر بۆ دروستکردنی دیزاینی جوانتری دابەشکردن بەرهەم دێنێت.

- سەرپەرشتیاری بەهێزی باش:

ناوبانگ و ساختوری خۆی دەپارێزێت و لەگەڵ ئەوەشدا سبکە و ئاسانە بۆ هەڵگرتن یان شوێنگرتن.

- بەرزکردنەوەی سۆرەتی کارکردن:

پاراستنی باش دابین دەکات بۆ دژایەتی لە خراپبوون، خراپەکان و کیمیاوەرەکان، پاراستنێکی ماوەیەکی درێژ بۆ بەرهەمەکان کە بە مەودای زۆر بەکارهێنران.

- پاراستن لە گەرمی:

دەتوانێت بەرزی گەرمی هەڵوەشێنێت لە کاتی لاپەڕەدان و بەکارهێنانی کۆتایی، کە دەبێتە هۆی ناگۆڕان یان لەدەستچوونی ئەفەکتی مەتالیک.

پشتگیری کڕیار بە درێژایی ڕێک :

چارەسەری فیلمی تایبەت :

چارەسەری کردنی کێشە تایبەتەکانت

دوخانی کینەی ماددە چاپکردنە گەرمی تەنها نەبووەکان دوای لایەنکردن

ÇARESARÎ: Pêlîka Termal a Laminasyona Barmayî ya Tempratureyên Nizm

جیابوونەوەی چاپە دیجیتاڵەکانی تۆنەر دوای لایەنکردن

ÇARESARÎ: Pêlîka Termal a Laminasyona Dîjîtal

چەسبونەوەیەکی نزمی چاپە جەتی دوای لایەنکردن

ÇARESARÎ: Pêlîka Termal a Laminasyonê ji bo Çapkirina Inkjet

Çare :

هەمکاری قووڵ لەگەڵ بەشی توێژینەوەی زانکۆ بۆ بەرهەم هێنانی چارەسەری تایبەت n

پاشیەکی :

تایبەتمەندی سێلای روHS & REACH & موادی پەیوەندی لەگەڵ خواردن

Xizmetên piştî firotanê :

بۆ کێشەکانی بەرهەم، تکایە وێنە یان ڤیدیۆ بۆ بۆچووین بۆ مەبەستی ئێمە. قسەی سەر داهاتووی شوێنکاریی ئێمە هەموو هەوڵی دەدات بۆ یارمەتیدان لە چارەسەرکردن. بۆ یارمەتی تەکنیکی، دەستپێکردنمان بە ئێوە دەکەین بۆ ئەوەی نمونەی بەرهەمەکانتان بۆ بنێرن و لەگەڵ تیمی یارمەتی تەکنیکی تواناواوی ئێمە گفتوگۆ بکەن. فیدبەکی ئێوە بۆ ئێمە بەهایە.

Pakketkirin û bidrin :

پرسیارەکان و جووڵەکان پێکهاتوو :

پ1: ئایا شوێنکاری فاکتوری یان بازرگانی هەیه؟

وەڵام: ئێمە کۆمپانیایەکی دەکەین کە تەحقیقات و توێژینەوە، بەرهەمهێنان و فرۆشتن دەکات.

پ2: چۆن کوالیتی بەرهەمەکانتان دادەزانن؟

وەڵام: کۆنتڕۆڵی کوالیتی لە سەرەتاوە تا کۆتایی - کۆنتڕۆڵی نائاسایی بۆ درەختی قورسی، دیاریکردنی بەهای کۆرۆنا، تاقیکردنەوەی جێگیری چوولاندن، و پاکەتکردنی کارایی.

پ3: سەرەکیترین بەرهەمەکانتان چییە؟

وەڵام: ئێکۆ پۆرتۆفۆلیۆیەکی گەورەی بەرهەمی هەیە بۆ خزمەتگوزاری کردنی جیهانی کار و صنعت، لەوانە فیلمی لامینەی گەرمی BOPP، فیلمی لامینەی چوولاندنی دیجیتاڵی زۆر چوول، فیلمی لامینەی گەرمی بۆ چاپی ئینکجێت، فۆیلی دیجیتاڵی تۆنەر، فیلم و کاغەزی DTF، فیلمی گەرمی دابخستنەوە، و هتد.

پ4: ئایا دەتوانم نمونە یان فرۆشتنی آزمایشی بۆ تاقیکردنەوە بگرم؟

وەڵام: بەڵێ، ئێمە نمونەی بەخۆڕایی دابین دەکەین، جیاتی نمونەکە 320 مم * 30 مەتر بۆ هەر ڕۆلێک. تەنها دەبێت هەنگاوی ناوبراو بپەرێنم.

P5: ئەمەن چ سەرڤیسێک دەتوانین بەدەست بهێنین؟

وەڵام: ئێمە هەموو توانای پشتگیری کڕیار دابین دەکەین، لە جملەی خزمەتگوزاری پیشەیی، چارەسەری تایبەت، نمونەی بەخۆڕایی، فرۆشتنی تاقیکردنەوە، کۆمەڵە زانیاری بارەی بەرهەم، شورا و ڕاوێژی تەکنیکی، تەواو کردنی ڕاپرسی کرداری لاگیستی، پرۆسەیەکی تەواو بۆ شیکایی کڕیار.

پ6: ئەمەن چ جۆرە مەبلەغی پارەدانێک دابین دەکەین؟

وەڵام: ئێمە EXW, FOB, CIF, DAP, DDP، و غەرەکان دابین دەکەین.