How to keep the thermal lamination film in good condition?

Thermal lamination film, as one of the important post-printing processing materials, is of undeniable significance in the packaging printing industry. Proper storage can enable the pre-coated film to perform its functions better. Here are a few suggestions:

• Store In A Cool, Dry Environment

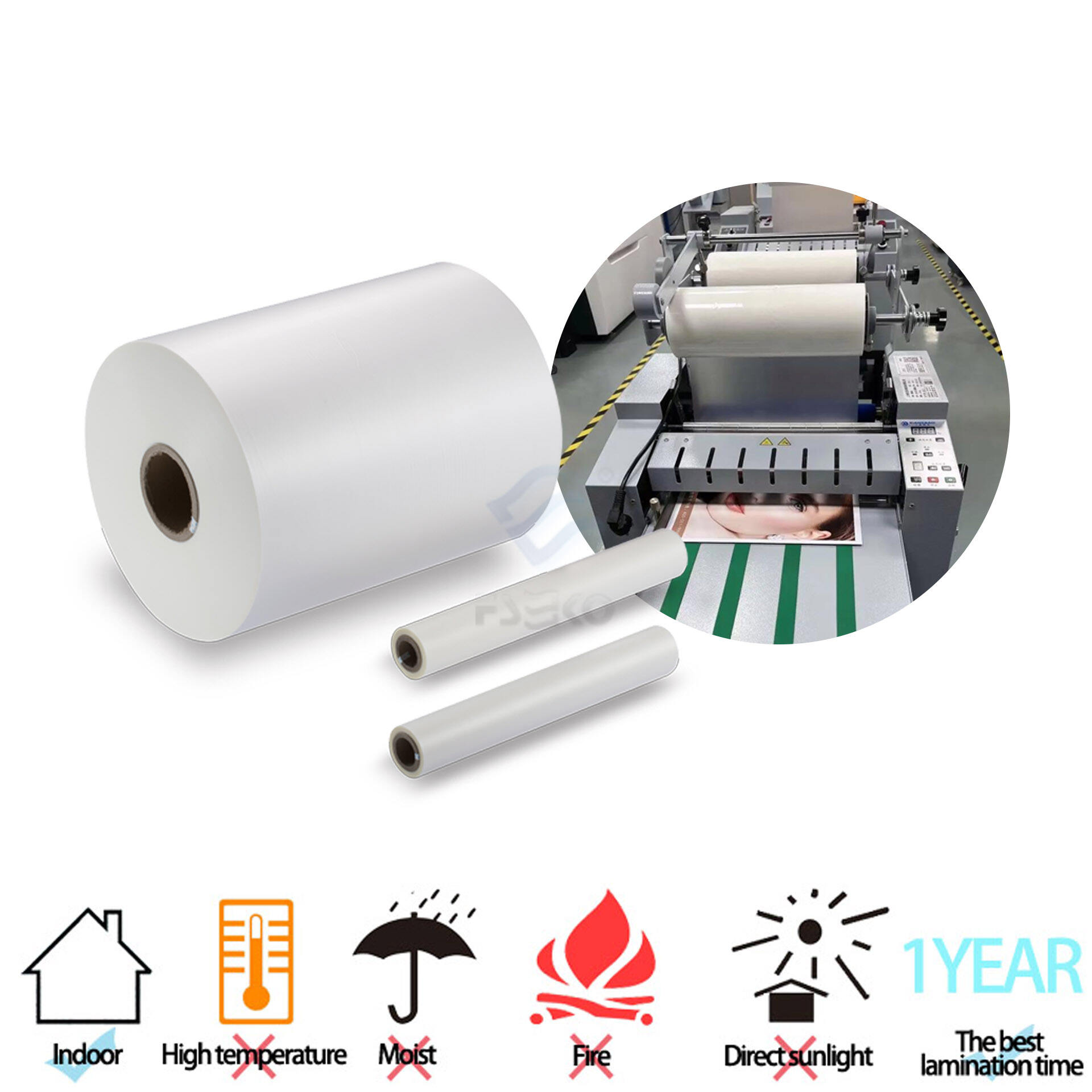

The thermal lamination film should be stored in a cool, dry place away from direct sunlight or extreme temperature fluctuations. Heat and moisture can affect the adhesive properties of the film, causing it to lose its effectiveness or possibly stick together.

• Keep Away From Sharp Objects

Avoid storing film where there are sharp objects that could puncture or tear the film. This may render the film damaged or unusable.

• Use Protective Packaging

Wrap thermal laminating film rolls in suitable packaging materials such as bubble wrap, top and bottom boxes or cartons to provide an extra layer of protection. Make sure the packaging is tightly sealed to keep out dust, moisture, and other potential contaminants.

• Avoid Excessive Weight

Do not stack heavy objects on top of film rolls, as this may cause the film to warp, crush, or lose its integrity. Store rolls in an upright position to prevent them from bending or warping.

• Handle With Care

When handling or moving film rolls, handle with clean, dry hands to prevent transfer of dirt or oil. Avoid touching the adhesive side of the film as this will affect its proper use.

• Rotation Inventory

If you have multiple rolls, it is recommended to implement a first-in first-out rotation system. This ensures that old volumes are used before new ones, preventing them from being stored for too long.

By following these guidelines, we can maintain the quality of the laminating film and ensure it remains in top condition for future use.