Choosing the right thickness of lamination film is crucial for achieving optimal results in various applications, whether it's for post-press processing, luxury packaging, flexible packaging, or any other field where Guangdong EKO Film Manufacture Co., Ltd.'s products are utilized. At EKO, we understand that different projects and materials require different levels of thickness to ensure durability, aesthetics, and functionality.

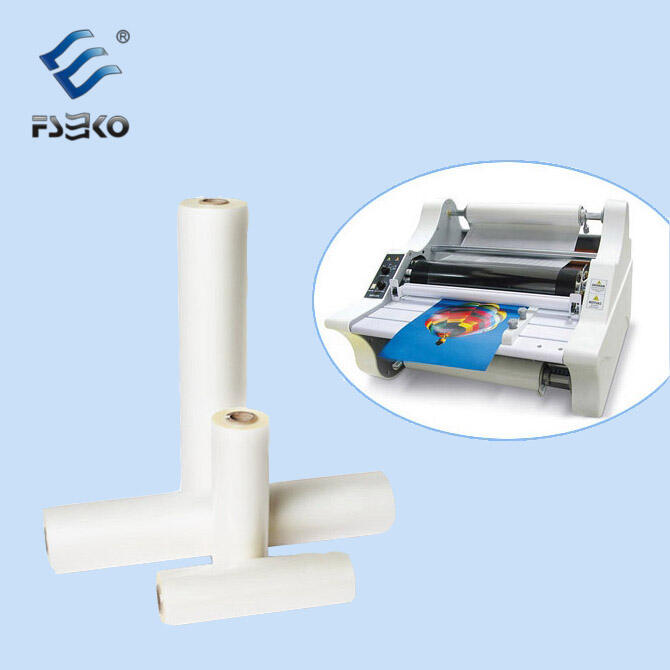

The thickness of lamination film is typically measured in microns (μm). For general purposes, such as standard document lamination, a thinner film, usually around 80-125μm, may be sufficient. This thickness provides a good balance between protection and cost-effectiveness, offering a clear, shiny finish that enhances the appearance of the document while keeping it relatively lightweight and flexible.

However, when it comes to more demanding applications, like luxury packaging or products that require extra durability, a thicker lamination film becomes necessary. Films in the range of 150-250μm offer enhanced protection against scratches, moisture, and general wear and tear. They provide a more substantial feel, which can elevate the perceived value of the packaged item. For instance, in high-end cosmetics or electronics packaging, a thicker lamination film not only protects the product but also adds a touch of sophistication.

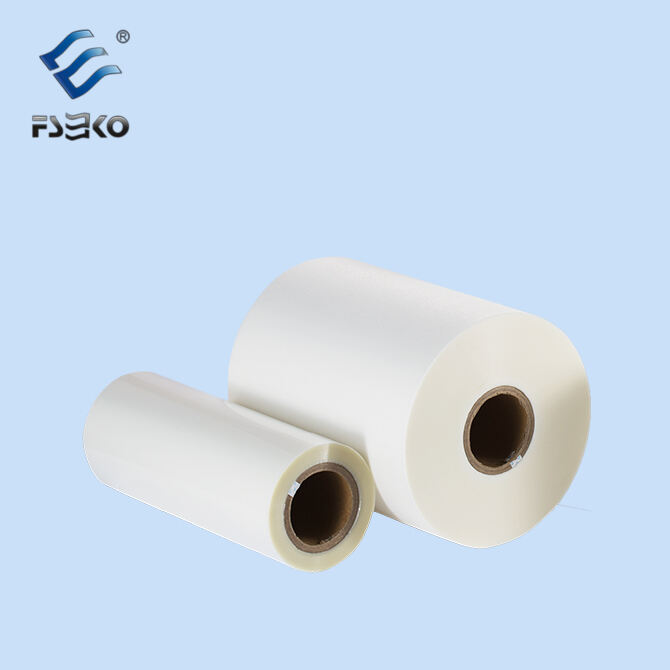

In the field of flexible packaging, where the film may be subjected to bending, folding, and even some stretching, the choice of thickness is even more critical. A film that is too thin may tear easily, compromising the integrity of the packaging and the product inside. On the other hand, an overly thick film could make the packaging difficult to handle and may not be cost-effective. EKO's thermal lamination film for flexible packaging comes in a variety of thicknesses, carefully engineered to provide the right amount of flexibility and strength for different flexible packaging applications.

Another factor to consider when deciding on the thickness of lamination film is the printing method used. For inkjet printing, a specific thickness may be recommended to ensure proper adhesion of the ink and to achieve the desired print quality. EKO's thermal lamination film for inkjet printing is formulated to work seamlessly with this printing technology, and the appropriate thickness is selected to optimize the printing and lamination process.

When it comes to digital printing, which has become increasingly popular due to its ability to meet personalized and short-run printing needs, the thickness of the lamination film also plays a role. Digital thermal lamination film from EKO is designed to complement digital printing processes. Thinner films may be preferred for some digital printing applications to maintain a lightweight profile and reduce costs, while thicker films can be used for projects that require a more robust and durable finish.

It's also important to note that the substrate onto which the lamination film is being applied affects the choice of thickness. For example, when laminating a thick cardboard or a rigid material, a thicker film may be necessary to provide adequate adhesion and protection. In contrast, for a thin paper or a delicate material, a thinner film may be more appropriate to avoid adding unnecessary bulk.

At Guangdong EKO Film Manufacture Co., Ltd., we offer a wide range of lamination film thicknesses to cater to the diverse needs of our customers. Our BOPP thermal lamination film, digital thermal lamination film, and other products are available in various thickness options, allowing you to select the one that best suits your specific project requirements. Our experienced team is also available to provide guidance and recommendations based on your application, ensuring that you make the most informed decision when it comes to choosing the right thickness of lamination film. By selecting the appropriate thickness, you can achieve the desired level of protection, aesthetics, and functionality for your products, enhancing their overall quality and market appeal.