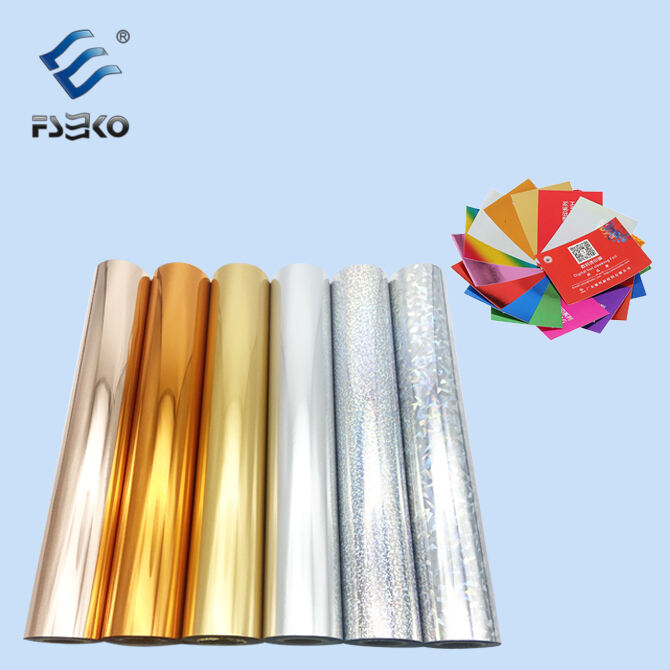

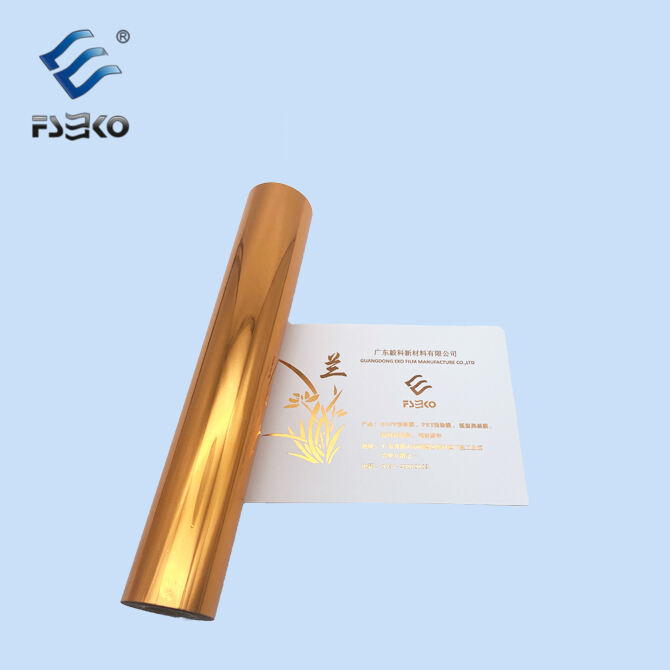

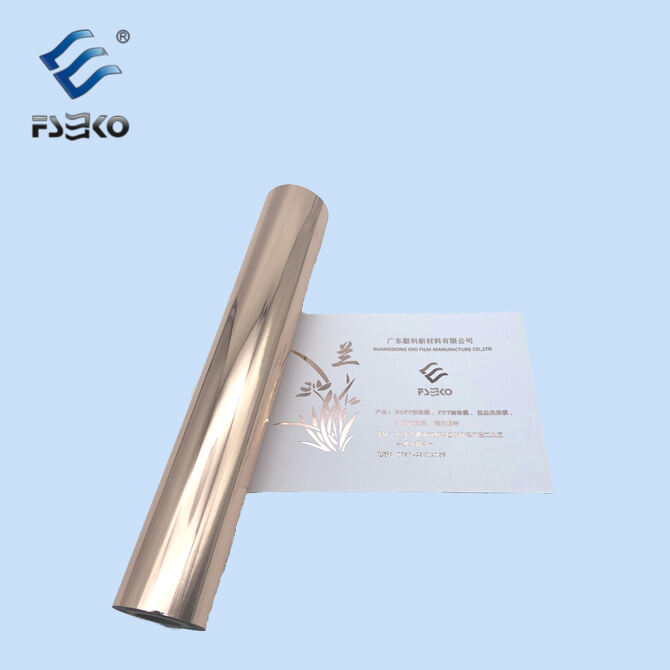

When it comes to adding a touch of elegance and shine to printed materials, both toner foil and traditional foil are popular choices. Guangdong EKO Film Manufacture Co., Ltd., with its expertise in the printing laminating materials industry since 1999, can help you understand the differences between these two options. Toner foil is a relatively new technology that is used in conjunction with digital printing. It works by applying a special foil to the printed surface using heat and pressure. The foil adheres to the toner on the print, creating a metallic or glossy effect. One of the main advantages of toner foil is its versatility. It can be used with a wide range of digital printing machines and does not require the use of plates or dies, as is the case with traditional foil stamping. This makes it a more cost - effective and efficient option for short - run printing projects or when you need to make frequent changes to the design. Toner foil also offers a high level of detail and accuracy. It can reproduce intricate designs, fine lines, and small text with ease, making it ideal for applications such as business cards, invitations, and packaging where precision is important. Additionally, toner foil is available in a variety of colors and finishes, including metallic, holographic, and matte, allowing you to achieve a wide range of effects. Traditional foil stamping, on the other hand, is a more established and traditional method of adding foil to printed materials. It involves the use of a metal die, which is heated and pressed onto the foil and the substrate, transferring the foil to the print. Traditional foil stamping is known for its high - quality, professional - looking results. It can create a deep, rich metallic effect that is difficult to achieve with other methods. The foil used in traditional stamping is also available in a wide range of colors and finishes, including gold, silver, copper, and specialty colors. However, traditional foil stamping has some limitations compared to toner foil. It requires the creation of a custom die for each design, which can be time - consuming and expensive, especially for small - quantity orders. It is also less suitable for intricate designs or fine details, as the die may not be able to reproduce them accurately. In terms of cost, toner foil is generally more cost - effective for short - run printing projects, while traditional foil stamping may be more economical for large - quantity orders due to the lower per - unit cost of the foil and the ability to reuse the die. In conclusion, the choice between toner foil and traditional foil depends on your specific needs and requirements. If you need a versatile, cost - effective option for short - run printing projects with high - detail designs, toner foil may be the right choice for you. If you're looking for a high - quality, professional - looking metallic effect for large - quantity orders, traditional foil stamping may be a better fit.