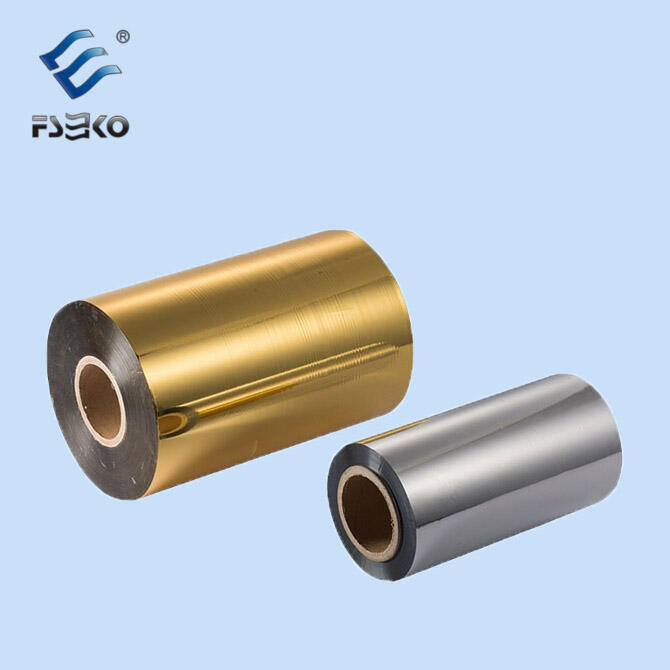

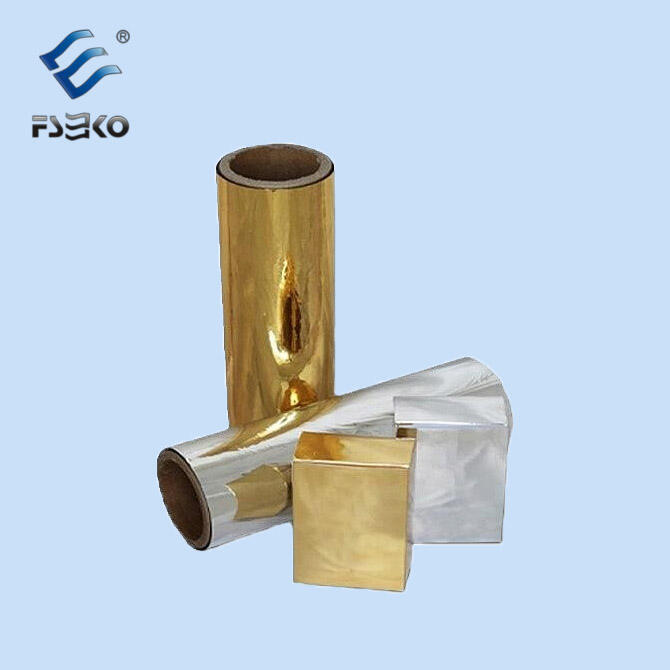

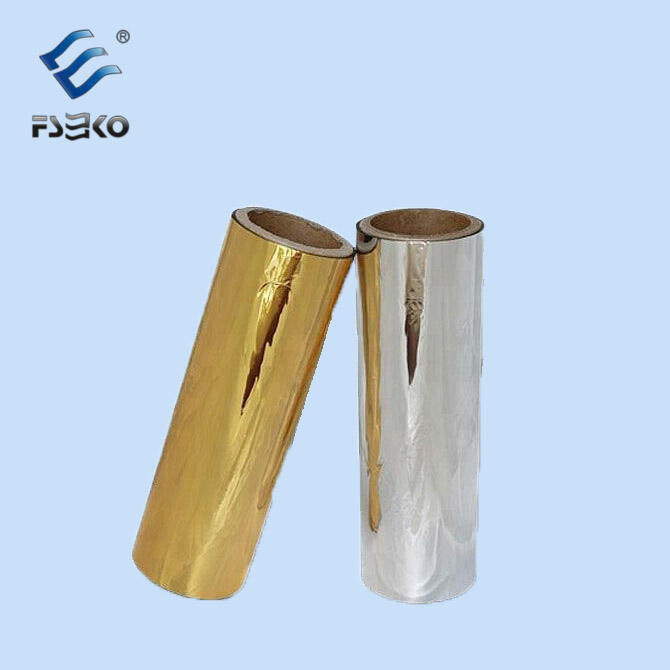

Metalized lamination film, offered by Guangdong EKO Film Manufacture Co., Ltd., a company with extensive experience in the printing laminating materials industry since 1999, works through a process that involves depositing a thin layer of metal onto a base film to create a unique and visually appealing finish. The first step in the production of metalized lamination film is the selection of the base film. Common base films used include BOPP (Biaxially Oriented Polypropylene) and PET (Polyethylene Terephthalate). These films provide a strong and stable foundation for the metal layer. The metal deposition process typically takes place in a vacuum chamber. A high - purity metal, usually aluminum, is heated until it vaporizes. The vaporized metal atoms then travel through the vacuum chamber and deposit onto the surface of the base film. The thickness of the metal layer can be controlled precisely to achieve the desired level of opacity and reflectivity. Once the metal layer is deposited, a protective coating may be applied to the film. This coating serves several purposes. It protects the metal layer from scratches, abrasion, and corrosion, ensuring the long - lasting appearance of the metalized film. It also improves the film's adhesion properties, making it easier to bond to the substrate during the lamination process. During the lamination process, the metalized film is combined with the substrate, such as paper, cardboard, or another type of film, using heat and pressure. The heat activates the adhesive on the metalized film, causing it to bond securely to the substrate. The pressure ensures that the bond is strong and uniform, creating a durable and long - lasting laminate. The metalized layer on the film gives it a distinctive metallic appearance. It can reflect light, creating a shiny and eye - catching finish. This makes metalized lamination film ideal for applications where visual impact is important, such as in the packaging of luxury goods, cosmetics, and high - end food products. It can also enhance the perceived value of the product, making it more attractive to consumers. In addition to its aesthetic benefits, metalized lamination film also offers some functional advantages. The metal layer can provide a barrier against moisture, oxygen, and UV rays, helping to protect the contents of the package and extend the shelf life of the product. It can also improve the film's opacity, preventing light from passing through and potentially damaging sensitive products. At Guangdong EKO Film Manufacture Co., Ltd., we have mastered the art of metalized lamination film production. Our advanced technology and strict quality control ensure that our metalized lamination films are of the highest quality, providing both visual appeal and functional performance for a wide range of applications.