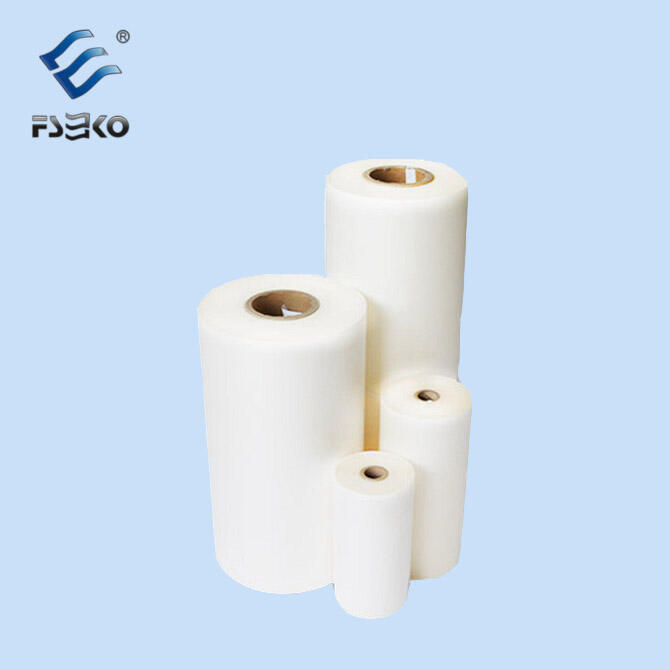

When it comes to enhancing the appearance and durability of printed materials, heat lamination film and UV coating are two popular options. Guangdong EKO Film Manufacture Co., Ltd., with its extensive experience in the field of printing laminating materials since 1999, can provide valuable insights into the differences between these two methods. Heat lamination film, such as our BOPP thermal lamination film and digital thermal lamination film, offers several advantages. One of the main benefits is its versatility. It can be applied to a wide range of materials, including paper, cardboard, and even some types of plastic. This makes it suitable for various applications, from business cards and brochures to packaging materials. Heat lamination film also provides excellent protection against moisture, dirt, and UV rays. It creates a durable barrier that helps to preserve the quality of the printed material over time. Additionally, heat lamination film can come in different finishes, such as glossy, matte, and soft - touch, allowing for a customized look. On the other hand, UV coating is a liquid coating that is applied to the surface of the printed material and then cured using ultraviolet light. UV coating provides a high - gloss finish that can enhance the colors and make the printed material stand out. It is also very durable and resistant to scratches and abrasions. However, UV coating has some limitations compared to heat lamination film. It is typically more expensive, especially for large - scale applications. Additionally, UV coating can be more difficult to apply evenly, which may result in some inconsistencies in the finish. In terms of environmental impact, heat lamination film can be a more eco - friendly option. We at EKO are committed to social responsibility and have developed a series of environmentally friendly and recyclable composite products, including some of our heat lamination films. UV coating, on the other hand, may contain volatile organic compounds (VOCs) that can be harmful to the environment. When choosing between heat lamination film and UV coating, it's important to consider the specific needs of your project. If you need a versatile, cost - effective, and environmentally friendly solution that offers good protection and a variety of finish options, heat lamination film may be the better choice. However, if you're looking for a high - gloss finish and are willing to pay a higher price, UV coating could be a suitable option.