Understanding Metalized Lamination Film and Its Visual Impact

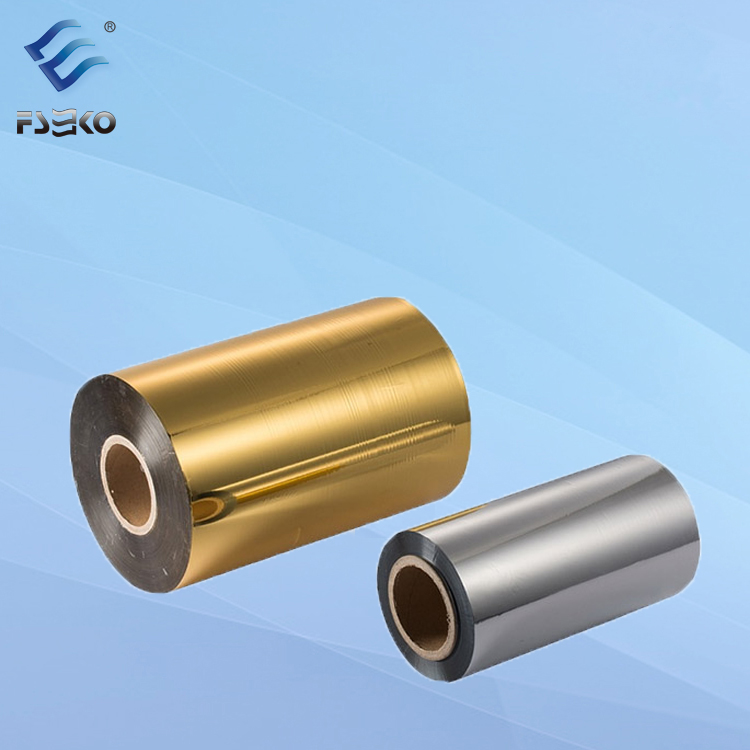

What Is Metalized Lamination Film?

Metalized lamination film is basically made by combining materials such as PET or BOPP with a super thin layer of aluminum deposited via vacuum metallization techniques. What this does is create that shiny reflective look we often see on product packaging, yet still keeps the original material flexible enough to handle without breaking. According to some recent market data from 2025, around two thirds of all high end packaging solutions actually use metallized BOPP films because they offer good value for money compared to other options available in the market today.

The Science of Reflectivity and Metallic Luster in Design

What makes this material stand out visually is the thin layer of aluminum deposited through vapor processes, typically around 20 to 30 nanometers thick. This coating reflects light at rates between 85% and 95%, creating what's called specular reflection where light bounces evenly across the surface instead of scattering randomly like regular foil does. For design purposes, this characteristic lets creators mimic chrome looks or boost those eye-catching holographic effects all while keeping things lightweight. Many product designers find this particularly useful when they want that premium finish without compromising on weight considerations for their final products.

How Metalized Films Elevate Aesthetic Value in Modern Packaging

Brands report 23% higher shelf engagement for products using metalized laminates compared to conventional materials, according to a 2024 Packaging Neuroscience Study. The technology enables three strategic advantages:

- Depth illusion: Reflective surfaces make logos appear floating

- Contrast amplification: Metallic backgrounds boost color saturation by 40%

- Premium signaling: 78% of consumers associate metallization with luxury

Leading manufacturers now combine matte varnishes with selective metallization to create "spot glitter" effects that comply with recyclability standards.

Key Types and Manufacturing Processes of Metalized Lamination Film

Common Substrates: PET, BOPP, and CPP Compared

When it comes to metalized lamination films, choosing the right substrate material is absolutely critical. The main players in this space are PET (Polyethylene Terephthalate), BOPP (Biaxially Oriented Polypropylene), and CPP (Cast Polypropylene). These three dominate most industrial applications because they each bring something different to the table. PET stands out for its exceptional clarity and tensile strength, which makes it great for those shiny packages that need to last through transportation and display on store shelves. Then there's BOPP, which manages to strike a nice balance between being flexible enough for curved surfaces yet still resistant to moisture damage. And finally we have CPP, which really shines when heat sealing is required, especially in things like snack food packaging where the seal needs to hold up during shipping but also open easily when someone wants a bag of chips.

| Substrate | Clarity | Flexibility | Barrier Performance |

|---|---|---|---|

| PET | High | Moderate | Excellent |

| BOPP | Medium | High | Good |

| CPP | Low | High | Moderate |

Vacuum Metallization Process: From Vapor Deposition to Film Coating

This precision-driven method vaporizes aluminum in a vacuum chamber, depositing a 20–30 nm metallic layer onto substrates. The controlled environment ensures uniform reflectivity while maintaining film flexibility. Post-metallization, acrylic or polyurethane coatings are applied to enhance scratch resistance and print adhesion.

Performance Advantages of PET-Based Metalized Films

PET’s molecular structure delivers unmatched benefits:

- 40% higher tensile strength than BOPP alternatives

- Superior resistance to chemicals and temperature fluctuations

- Optical clarity that preserves holographic and iridescent effects

Balancing Visual Appeal and Environmental Considerations

While metallized films create shelf-stopping brilliance, manufacturers now optimize aluminum usage through thinner coatings (≈15 nm) and mono-material structures. Recent advancements in plasma pretreatment allow 30% reduced metal consumption without compromising reflectivity, aligning luxury aesthetics with circular economy goals.

The Lamination Process: Creating High-Impact Visual Composites

Step-by-Step Guide to Film Lamination and Composite Formation

Lamination turns ordinary metalized film into eye-catching composite materials by carefully stacking layers on top of each other. To start with, manufacturers usually prep the base material's surface so the adhesive will stick properly later on. After that comes the really interesting part where they deposit a super thin layer of aluminum using vacuum technology, which gives these films their amazing reflective properties reaching almost 98% reflectivity in some cases. What happens next depends on whether they use hot or cold rollers for the actual lamination process. Either way, special pressure sensitive glues do the job of attaching the shiny film to whatever printed material needs decorating, all without messing up that beautiful metallic finish everyone loves so much in packaging applications today.

Adhesive Selection and Bonding Techniques for Optimal Clarity and Durability

Adhesives must balance optical clarity with chemical resistance. Key considerations include:

- Viscosity: Low-viscosity urethane adhesives minimize light diffraction for uninterrupted metallic visuals

- Curing speed: Fast-curing formulations (<15 seconds) prevent substrate warping

- Temperature tolerance: Stable performance between -40°C to 121°C ensures packaging integrity during transport

Advanced hybrid adhesives now enable peel strengths exceeding 8 N/15mm without compromising recyclability.

Quality Control in Roll-to-Roll Metallization for Consistent Output

Modern facilities implement three critical checks during continuous production:

| Parameter | Measurement Method | Tolerance Range |

|---|---|---|

| Coating Thickness | X-ray fluorescence | ±0.5 μm |

| Optical Density | Spectrophotometry | ΔE ≤1.5 vs master sample |

| Adhesive Coverage | High-speed cameras | ≥95% surface contact |

Automated defect detection systems using AI-powered vision technology now achieve 99.97% accuracy in identifying micron-level coating inconsistencies during high-speed reel processing.

Printing and Decorative Techniques for Enhanced Visual Effects

Ink Compatibility and Adhesion Challenges on Reflective Surfaces

When it comes to printing on metalized lamination film, regular inks just won't cut it. These special reflective surfaces need inks specifically designed for them. Most standard solvent-based options simply don't stick properly, which leads to problems like ink peeling off or colors looking patchy across the print. That's where UV-curable and water-based acrylic inks come into play. They work better because they have lower surface tension, making them cling to those tricky metallic surfaces. And with LED UV printing technology, printers can actually get pretty accurate results even on these challenging materials. For manufacturers working with these films, checking how opaque the ink coverage is becomes really important. Getting at least 95% coverage helps stop that annoying metallic shine from showing through and messing up the final graphic appearance.

Maximizing Color Contrast and Graphic Clarity on Metalized Films

Getting those striking color contrasts right on metal surfaces takes some careful planning when it comes to applying ink layers. Most professionals start with white base coats because they help cut down on how reflective the surface is. This simple step actually makes colors look truer and vibrant about 30 to 40 percent better than if someone tried printing directly onto the material. For real depth in designs, many artists reach for Pantone Metallics along with dense pigment formulas. At the same time, there's this technique called micro-texturing that works wonders at minimizing unwanted shine coming off the aluminum backing of these films. It's all part of what makes printed graphics stand out so well against shiny backgrounds.

Advanced Decoration: Embossing, Matte Finishes, and Selective Coatings

Tactile effects like embossing amplify the luxury appeal of metalized lamination film. Laser-etched patterns combined with soft-touch matte coatings create sensory contrast against glossy metallized areas. Selective holographic coatings can generate iridescent effects visible at 15°–75° viewing angles, a technique refined through nanoscale vapor deposition advancements.

Case Study: Luxury Cosmetic Packaging with Printed Metalized Film

A 2024 limited-edition fragrance launch used PET-based metallized film with gold foil stamping and gradient UV spot coatings. The packaging’s light-reflective properties increased shelf visibility by 70% in retail lighting simulations, contributing to a 22% higher click-through rate in digital campaigns compared to standard glossy boxes.

Applications and Trends in Packaging with Metalized Lamination Film

Metalized lamination film has become a cornerstone of modern packaging, blending functional performance with eye-catching aesthetics. Its adoption grew 18% annually from 2020–2025 as brands leverage its dual ability to protect products and amplify shelf presence across industries.

Functional and Decorative Uses in Food, Pharma, and Consumer Goods

More than seventy percent of packaging companies have started going with metalized films lately, especially when it comes to important stuff like those little pill blisters and snack bags. For medicines, these special films act as really good moisture barriers, keeping things dry even though they're pretty thin (something like less than 0.01 grams per square meter per day). Plus, they make it easier to tell if someone has messed with the package. When it comes to food products, manufacturers love how well these materials block out light which helps keep products fresh longer on store shelves. Take chocolate wrappers for instance - switching from regular coatings to metalized PET films cuts down on that annoying fat bloom problem by about forty percent according to what some industry folks are saying.

Flexible Packaging: Merging Durability with High Visual Appeal

The flexible packaging sector now accounts for 58% of metalized film demand, driven by e-commerce’s need for lightweight yet damage-resistant mailers. Metallized BOPP films (15–30 micron thickness) dominate here, offering 3x the puncture resistance of plain films while maintaining foldability for shaped pouches.

Holographic and Iridescent Effects Driving Brand Differentiation

Brands using holographic metalized films report 23% higher product recall rates in consumer tests. Limited-edition cosmetic releases increasingly combine iridescent finishes with matte lamination—a technique that reduces fingerprint visibility by 65% while maintaining metallic sheen.

Consumer Psychology and ROI: Why Shiny Stands Out on Shelves

Neuroscience studies confirm shoppers spend 400ms longer gazing at metallized packaging versus matte alternatives. This visual attention translates to tangible returns—products in metalized wrappers achieve 17% faster stock turnover in convenience retail channels.

FAQ about Metalized Lamination Film

What materials are metalized lamination films made from?

Metalized lamination films are primarily made by combining materials like PET or BOPP with a thin layer of aluminum deposited through vacuum metallization techniques.

How does metalized lamination film improve shelf engagement?

Products with metalized laminates report 23% higher shelf engagement due to enhanced depth illusion, contrast amplification, and premium signaling provided by the reflective surfaces.

What are the performance advantages of PET-based metalized films?

PET-based metalized films offer 40% higher tensile strength compared to BOPP alternatives, superior resistance to chemicals and temperature changes, and excellent optical clarity.

Why is ink compatibility a challenge on metalized films?

Regular inks often don't adhere well to the reflective surfaces of metalized films. Special UV-curable and water-based acrylic inks with lower surface tension are needed for proper adhesion and graphic clarity.

What industries benefit most from using metalized lamination films?

Industries such as food, pharmaceuticals, and consumer goods benefit significantly from metalized lamination films for their moisture barrier properties, light blocking capabilities, and visual appeal.

Table of Contents

- Understanding Metalized Lamination Film and Its Visual Impact

- Key Types and Manufacturing Processes of Metalized Lamination Film

- The Lamination Process: Creating High-Impact Visual Composites

- Printing and Decorative Techniques for Enhanced Visual Effects

- Applications and Trends in Packaging with Metalized Lamination Film

-

FAQ about Metalized Lamination Film

- What materials are metalized lamination films made from?

- How does metalized lamination film improve shelf engagement?

- What are the performance advantages of PET-based metalized films?

- Why is ink compatibility a challenge on metalized films?

- What industries benefit most from using metalized lamination films?